A book that enjoys considerable fame in the manufacturing and supply chain environment is the one written by Eliyahu M. Goldratt and entitled “The Goal”. A perfect combination of novel and theory that helps to make the theory of constraints its own. This theory is also known as Theory Of Contraints or with the acronym TOC, and is useful to solve the typical problems of a factory. “The Goal”, however, is not only a great read that reveals the principles of TOC in a very practical and easy-to-understand way, but also contains valuable “hidden” lessons on the world of supply chain.

Goldratt’s “Hidden” Lesson

Alex is the manager of a struggling production facility. His factory has incomplete orders for weeks, tons of stock, large amounts of work in progress, and he is constantly losing money. He is given three months to transform this tragic situation and save the plant from imminent closure. 90 days later, the plant is not only profitable, but even the best in the division. How did Alex accomplish this miracle?

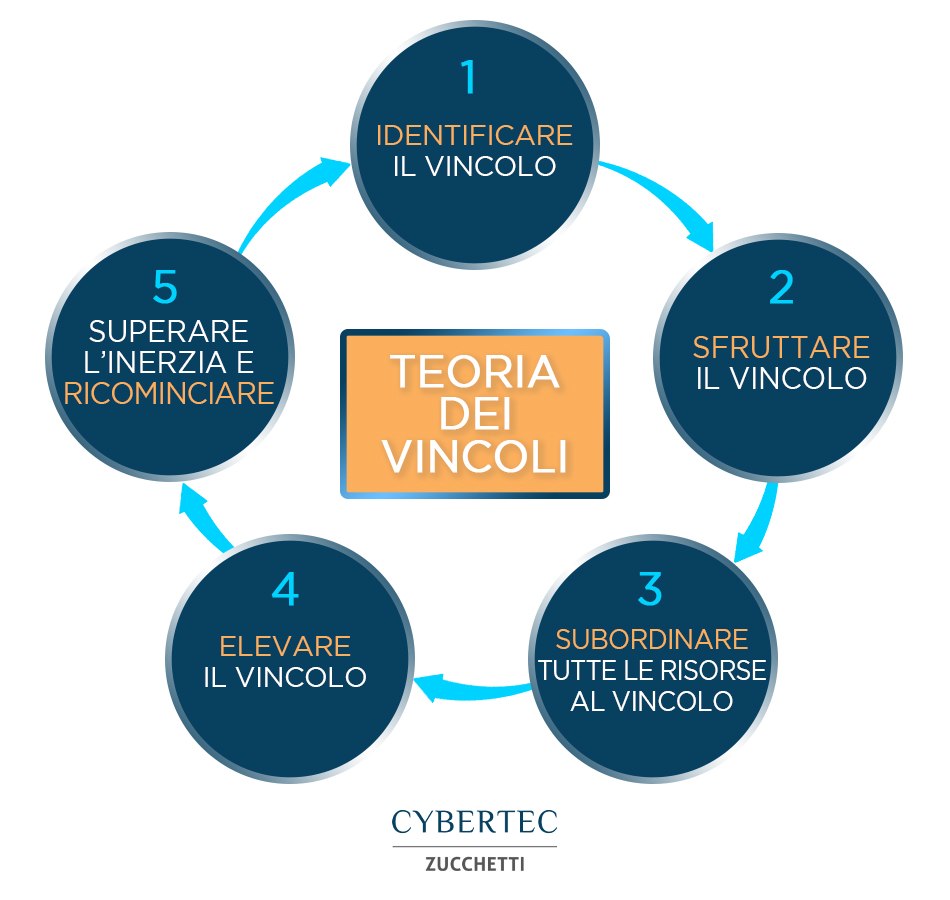

It all starts with five steps formally described as the theory of constraints. In simple terms, TOC is about identifying the constraints of a system, taking full advantage of its operation, and subordinating the rest of the system to the flow through the constraint. Once the flow of the system is leveled, the capacity of the constraint should be improved in every possible way. This process is repeated, in order to continuously improve the system.

The advantages of applying the Theory of Constraints

The advantages of constraint theory are diverse and include:

- Better product and service process throughputs

- Greater profitability thanks to the achievement of objectives

- Increased productivity, production capacity and average quality

- Reduced delivery times and inventory levels

- Increased service level

- Improving culture, staff engagement and problem solving

Goldratt’s 5 Steps of Constraint Theory

In Alex’s plant, the five steps look like this:

1. Open the bottlenecks: it is discovered that the bottlenecks are represented by the plant’s newest machine (NCX-10) and the heat treatment oven. Discover the bottlenecks with these tips.

2. Take advantage of bottlenecks: make sure that the NCX-10 machine and oven are always used at maximum capacity. Do this by eliminating downtime (i.e. making sure there are no interruptions) and reducing cycle time on the machines.

3. Subordinate the other production processes to the bottlenecks: with regard to quality control, for example, only suitable products should reach the bottlenecks (it is therefore necessary to move the quality control upstream of the NCX-10). Do not let the bottlenecks work on parts that will be discarded. It is recommended to establish a tag system (red and green) to give the right priority to the elements on which the rest of the system should work to guarantee the bottlenecks the available parts.

4. Increase the performance of bottlenecks: to increase the flow of bottlenecks it is useful to dedicate the necessary personnel to the two machines, outsource some of the work of the bottlenecks to external suppliers or even use alternative equipment, even if old and less efficient, that are able to carry out the activity of the bottleneck.

5. Once the bottlenecks have been unlocked, repeat the process to find out what the new constraint is.

“The Goal” is therefore not just a great reading that reveals the principles of OCD in an extremely practical and easy to understand way. Working at Cybertec you can see how the reality of manufacturing companies is complex and tends to get more complicated over the years. For this reason, simple but complete products such as the APS CyberPlan are essential to remain competitive and also as Goldratt would say “to do more with less”.

The different types of factories

According to the lexicon of constraint theory, there are four main types of factories (or plants). If you draw the material flow from the bottom up you will get the four types, which specify the material flow through a system and also provide some tips on where to look for typical problems. This type of analysis is known as Vati analysis since it uses the letters V, A, T and I to describe the types of plants. In more complex production facilities these four types can be found combined with each other in many ways, for example you can have a type A plant that feeds a type V. These four types of plant are:

- Plant V: The overall material flow is one-to-many.

An example is a plant that uses a raw material to produce many end products, such as foundries.

The main problem in type V systems is “theft”, which occurs when an operation (A) located immediately after a divergent point “steals” materials destined for another operation (B). Once the material has been processed by A, it cannot go back and be processed by B without significant reworking. - Plant A: The general material flow is many-to-one.

An example is a plant where many sub-assemblies converge towards a final assembly.

The main problem in type A plants is to synchronize all the converging lines so that each one delivers the semi-finished product to the final assembly point, at the right time. - Plant T: The general flow is that of a plant I (or has several lines), which is then divided into many assembly points (many-to-many). Most of the parts produced are used in multiple assemblies and almost all use multiple parts.

Custom devices, such as computers, are a good example of this type of plant.

As far as problems are concerned, type T plants suffer from both the synchronization problems typical of A plants (often the parts are not all available for assembly) and the “theft” problems of type V plants (one assembly steals parts that could have been used in another). - Plant I: the material flows along a sequence, such as an assembly line, and the main work is carried out along a linear sequence of events (one-to-one).

The constraint is the slowest operation.

Thanks to this list, the different types of production plants can be analysed, a useful aspect in the theory of constraints.

Learn how to “do more, with less”

Request a demo of the most advanced Advanced Planning and Scheduling Software in Italy, find out how the planning and scheduling solution can help your company to do more with a better use of resources. The CyberPlan solution uses techniques such as the drum buffer rope, the agile method and the study of bottlenecks. Learn more: