Let’s find out how it is possible to address and solve the recurring problems in companies producing cables for the transport of energy and information through the use of specialized production planning and scheduling tools. The main challenges are related to the world outside the company, regarding the delivery dates to be guaranteed to customers, but also internal, aimed at reducing production costs associated with frequent machine changes or set-ups on production lines.

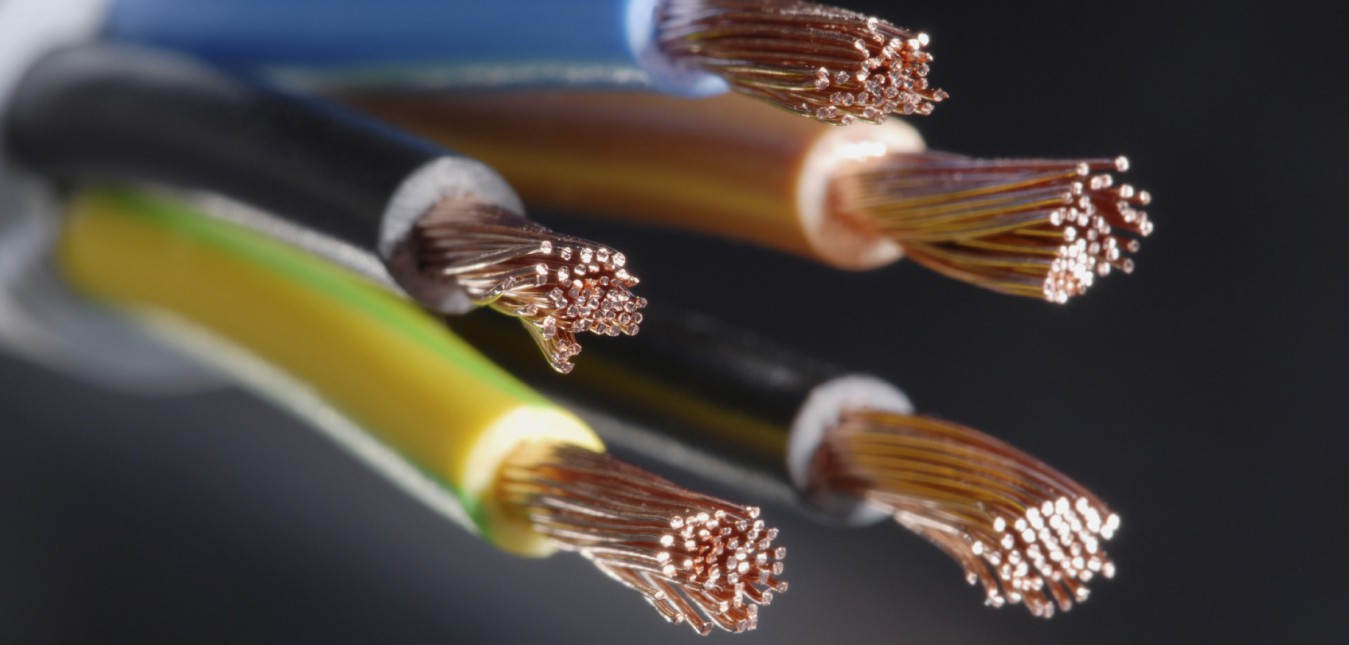

Production of cables for the transport of energy

The company that is the object of the project is a national company, producer of cables for the transport of energy, for medium and high voltage, operating on the national and international market. With a turnover of over 400 million and more than 1200 employees, distributed over several plants, it is a significant reality among companies in the sector. Production is managed on a contract basis, on specific orders from customers, including Enel.

The products

The company produces different types of cables that differ in:

- application (overhead cables, underwater cables, cables for high temperatures etc.),

- geometry (different sections depending on the application),

- external coatings (lead sheaths, oiled paper, etc.).

In addition to the main basic components, copper or aluminium conductor and compounds, for each type of cable other materials are added, different depending on the specific applications (e.g. steel cables with structural functions for aerial applications, external reinforcement for submarine cables, etc.). The structure of the product is divided into a bill of materials of up to 5 levels.

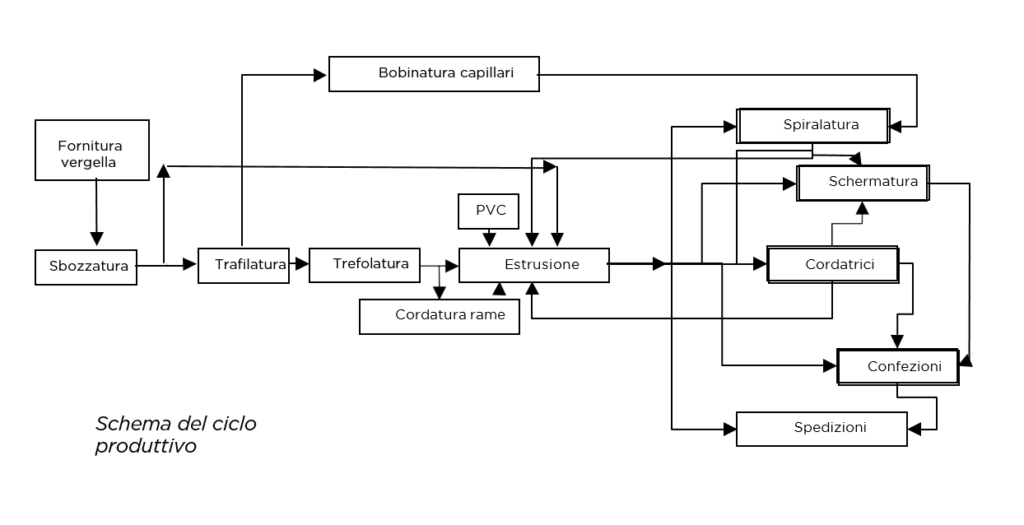

The production process

The production process develops according to a multi-level flow logic. The wire rod of conductive material is transformed into wire of variable section through a blanking process and subsequent cold drawing. The wires, in varying numbers depending on the applications, are wrapped together by a multi-wire machine and subsequently subjected to braiding. The strands obtained are wound together to create the strings. The ropes obtained are subsequently covered with hot-extruded insulating plastic material and cooled in water. On the “cores” thus obtained, a copper wire can be wound, in wide coils, with shielding functions. Everything is covered with protective foam and a second plastic sheath. The resulting material constitutes the component of the final three-phase cable which, in particular conditions of use, can in turn be covered by a sheath before commissioning. Each processing is carried out on the stretched material which is then wound on reels to be transported to the next processing machine.

Overall, the number of raw materials used for the production of the final cable is limited: copper or aluminium wire rod, copper wire, compounds and rubbers, fillers, cardboard are the main ones. Despite the reduced number of raw materials, the variability in the finished product is extremely wide and this causes numerous problems for the management of all codes.

Problems in the production process

Analysing the production flow of this reality, it emerged that, although only some components of the process were critical, the performance of the entire production system was affected:

- the raw materials are not particularly critical: the supply lead time is limited and manageable;

- the drawing phase does not constitute a production constraint, as the programming carried out at infinite capacity on it does not cause any management difficulties or production delays;

- the lines downstream of the drawing are critical, involving numerous set-ups, for the management of different rope/cable sizes, different coating colours, etc. The sub-optimal management of these lines results in difficulties in managing the delivery dates agreed with the customer and considerable internal costs due to frequent set-ups, or incomplete exploitation of resources.

The intervention needs on process management

At the beginning of the study on the reality in question, it was evident that the difficulty in managing and synchronizing the lines downstream of the drawing had as a consequence a low level of customer service, which in turn had an impact on the production reality not only in terms of image and customer satisfaction, but also in terms of penalties to be paid for failure to meet delivery dates (this is a very frequent problem for companies that operate with large public and private clients). To increase the level of customer service, it seemed that the only viable route was to use, where necessary, frequent machine changes, which followed the different orders being processed one after the other. Such a choice entailed frequent set-ups, which raised internal production costs and decreased production efficiency. To these costs were added others due to machine downtime caused by “sudden” shortages of material on the lines (due to incorrect programming). The decision to improve the level of customer service seemed to inevitably lead to an increase in internal production costs, which, however, was not to be met. To cope with this situation it was necessary to find a solution that would guarantee certain and reliable delivery dates and optimised and balanced production sequences.

Complete visibility and governance of production

The above problems have been addressed and solved by the company with the help of Cybertec technicians and with CyberPlan, the tool for planning and scheduling production. After an initial study phase of the production reality and its characteristics, the solution for the specific production reality was proposed. The first phase of the project was the implementation of the interface architecture, through which the complete integration between CyberPlan and the central information system is achieved. Subsequently, some minimal customizations were made to the package, after which the use of CyberPlan was started. The total time taken for the implementation of the entire project was 4 months. With the introduction of the new tool and some of its innovative and peculiar features, a new series of operations connected with production scheduling have become possible:

- generate production plans and production sequences that ensure greater customer service in terms of delivery dates and at the same time lead to a reduction in production costs;

- carry out simulations in a short time of different production scenarios, starting from different initial hypotheses (e.g. effect on the use of alternative machines, the insertion of a new order, etc.): this is possible thanks to the innovative technology with Ram database, which allows processing of large amounts of data and information in a very short time, and thanks to the advanced graphic interface, which allows the driven interactivity between instrument and operator;

- divide the workloads on similar machines, but with different capacities and quantify the commitment on each one: this is possible thanks to the finite capacity calculation of resources and the use of alternative cycles;

- react promptly to sudden changes in production through reprogramming of the plan (e.g. machine downtime): this is possible thanks to the speed in reworking the production plan in real time.

Service level, production efficiency and cost reduction

The new solution introduced has led to significant improvements, both in terms of customer service level and internal production efficiency. This result is the consequence of various factors directly or indirectly related to the overall company performance:

- the production sequences have been managed and piloted;

- production lead times have been reduced;

- increased reliability in delivery dates to the customer;

- the number of set-ups and tooling and consequently their average cost have been reduced;

- it was possible to have a reliable plan processing tool, which always provides consistent and repeatable results.

Top companies in the industry that have chosen Cybertec solutions

- Triveneta Cavi – has been planning and scheduling with the CyberPlan solution for 15 years; it has been active since 1965 and is one of the most important companies in the European market for the production of low and medium voltage cables for the industrial, domestic, energy distribution and renewable technologies sectors.

The constant growth of turnover and a policy of investment in research and production processes ensure the customer a continuous improvement in the quality standards of services and an increasingly complete range of electrical cables. With a solid presence in more than 25 countries around the world, the LTC group employs about 600 employees divided into its five offices for a total area of about 160 thousand m2, of which half is covered. - Italian Cable Company (ICC) – is a leading company in the field of cables for industry and energy transport with headquarters and production in Bolgare, in the province of Bergamo. It was born from the intuition and commitment of the Rota family that founded Rota Cavi in 1961, a company destined to follow a growth path of over fiftyyears on the national and international market.

- African Cables – CBI-electric african cables has been designing and manufacturing a full range of electric cables at the Vereeniging factory near Johannesburg since 1935. For over eightyyears, the growth of the production structure has gone hand in hand with technological progress, always with an eye to international trends.

- Essex – With a turnover of over €200 million 55,000 tons and two plants in Quattordio, ESSEX ITALY SpA is one of the leading companies in the world for the electrical winding conductors market. The range of products is wide, ranging from thin enamelled wires to large transposed cables for transformers. Its considerable industrial strength is traditionally oriented towards technological development and customer service.

- Fanton – Located in the municipality of Conselve, on an area of 30,000 square meters, of which 18,000 are productive and an office area of over 2,000 square meters that houses over 60 employees.

- Bruno Baldassari – is one of the leading manufacturers of low voltage electrical cables on the market. Technical and management resources, constantly in step with technological progress, allow “lean and punctual” production to meet the needs of the market, always attentive to product innovations.

CyberPlan for cable production planning and scheduling

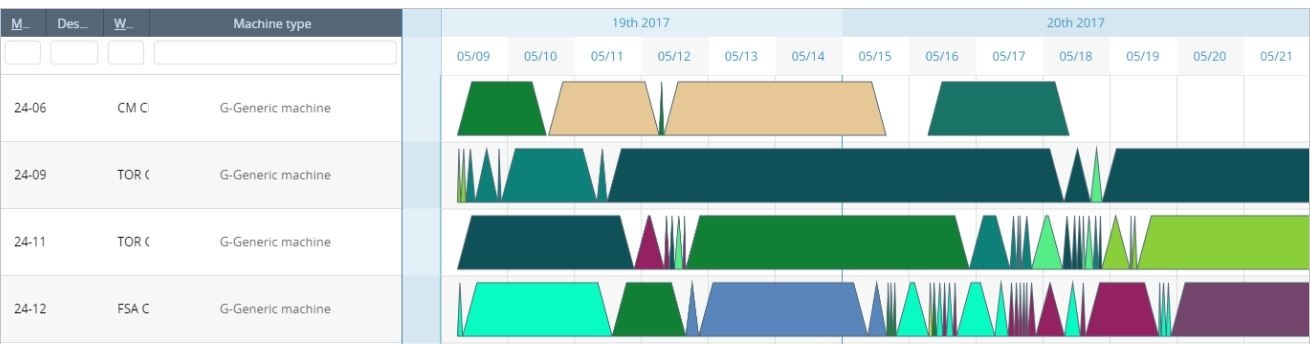

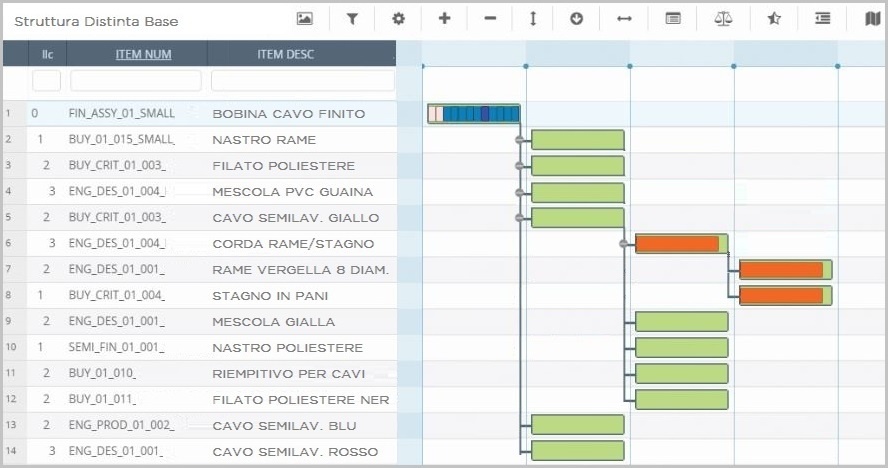

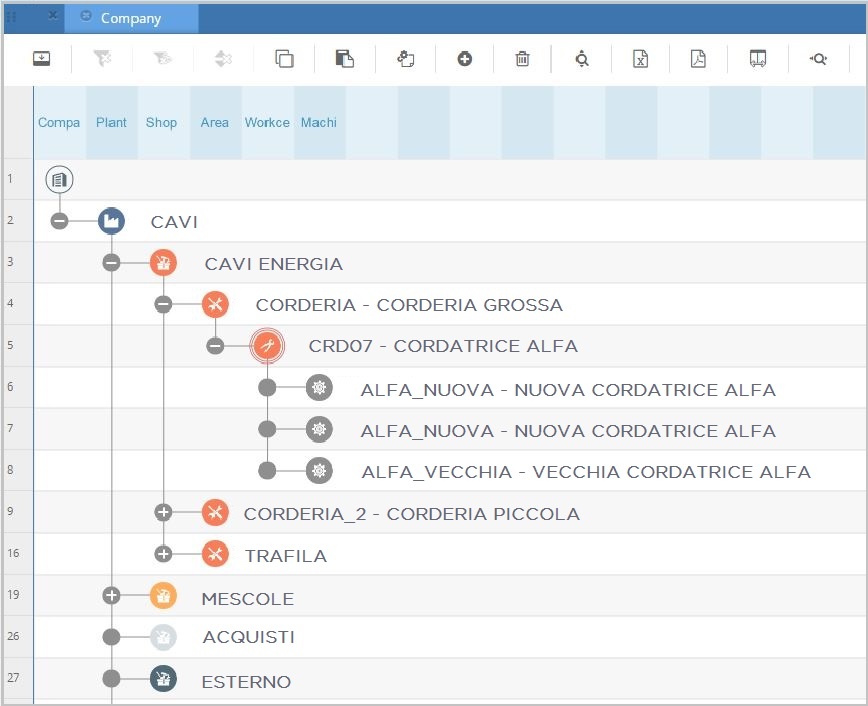

In the images below you can see the CyberPlan solution actually applied in the company for the production of cables for the transport of electricity:

- Bill of materials – The bill of materials of the sample material is divided into 4 levels. It is possible to identify all the components that make up the assembly.

- The business model – The structure of the company is schematized in CyberPlan on departments, areas, work centers, machines.

- Gantt machines and table performance – The first window shows the machines on which some machining is performed. Each task is related to the processing of a material, whose description and quantity appear in the figure. The second window displays the performance dashboard of the plan, which shows the measures relating to the active plan of the performance indicators previously chosen for verification.