4 ways to reduce traversal time in production.

Whatis production lead time?

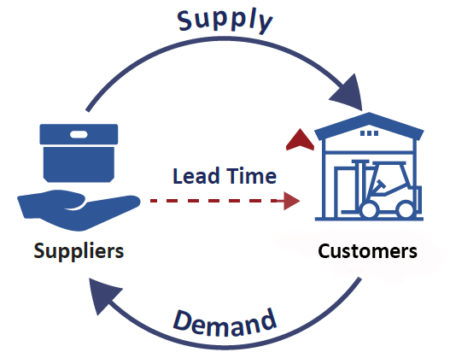

Lead time, or crossing time, in production, is the time that elapses between the arrival of raw materials and the deposit of the finished product.

Why is reducing production lead time so important?

Reducing the time needed to make the product is now increasingly important because it allows you to create a competitive advantage over competitors. The quality of the finished products has now risen and leveled off, to the point that it is taken for granted by the end customer. Hence, the time necessary to have the product is therefore a differentiating factor of primary interest to give the product to the customer who ordered it by the established date.

A reduction in production lead time also leads to a substantial reduction in production costs.

What factors influence lead time?

Have you ever received very different expected delivery times, from virtually identical product suppliers? There are many reasons behind this apparent strangeness, some of them are:

- Stock breakdown or lack of materials in the warehouse;

- Different lead times related to the materials;

- Non-standard products;

- Too many internal procedures;

- Various production efficiencies;

- Different production planning capabilities.

How to reduce lead time?

To reduce lead time, companies must pursue production optimization. The steps to optimise production are different, let’s look at them.

1. Reduce set-up times

The setup consists of the series of operations necessary to put any workstation in a position to carry out a new activity. Reducing preparation times therefore reduces the total time needed to make a product. Reducing set-up time also means reducing machine downtime and increasing compliance with On-Time Delivery.

2. Identify bottlenecks

A bottleneck, or constraint, is a step in the production process that causes a slowdown compared to the other phases. Like the neck of a bottle, in fact, the previously faster flow slows down and an accumulation of semi-finished products ready to be processed by the machinery or operator representing the bottleneck is formed. Identifying these constraints is therefore essential if you want to improve the production process.

3. Eliminate bottlenecks

The next step is to remove the limit that constraints represent for the company. This can be done by increasing resources at that point by purchasing additional machines of the same type, increasing the working hours of that machine or by finding alternative solutions to the method currently used.

4. S stop the bottlenecks

If it is not possible to remove the constraints (in English constraints), it must be ensured that they never remain inoperative but are always loaded and that they work at full capacity. This allows you to maximize what represents the minimum of production.

Reducing crossing times thanks to better planning

To reduce lead time, it is therefore essential to optimise internal production processes by saturating machinery and resources. Achieving the best organization of resources and processes, however, often causes an increase in planning complexity. For this reason, companies feel the need to equip themselves with tools that can support them in accelerating the planning and scheduling processes, improving the quality and feasibility of the plans produced.

Learn more about how to improve the production planning and scheduling process in the article “How to Accelerate the Production Planning Process.” In this article we will investigate the tools, processes and people needed to achieve an efficient supply chain.