KPIs are important indicators to improve the efficiency of the production process because they monitor performance trends. These are data sets that reflect or measure the efficiency, capacity and effectiveness of different aspects of production. They play a fundamental role especially when you consider that the data used by the MRP must have a certain degree of accuracy.

Whatis an MRP

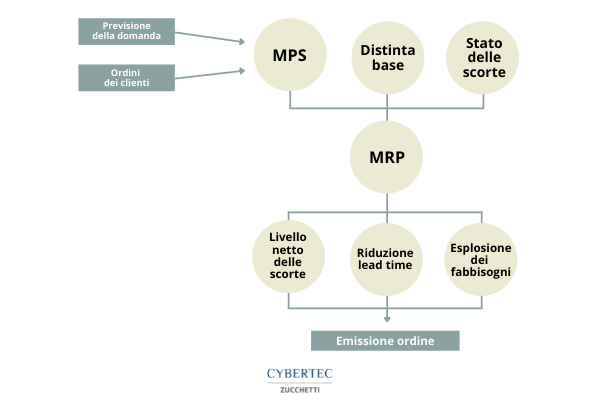

MRP is at the heart of any business planning process because it calculates the amount of materials and components needed to make a product. It includes all systems concerning the acquisition, production and delivery of the finished product. The MRP therefore allows you to plan production and purchase orders based on variable factors such as market demand and production lead time.

The main KPIs of the MRP

KPIs must be by definition specific, measurable, actionable, in line with objectives and updated. It is therefore important to base your decisions on metrics that matter, because unreliable KPIs can lead to risky decisions.

There are numerous KPIs that can be measured, but in practice it is good to focus on those that have a main role in your company. In particular, there are six KPIs that it would be good to focus on that can also be partly automated through ERP or MRP software.

On-time delivery

This KPI measures the punctuality of delivery, calculating shipments delivered on time compared to those that arrived late and highlighting any problems in the customer’s logistics. It is considered by many to be one of the most important KPIs because it gives information about customer satisfaction and can directly affect profits.

On-time supply

On Time Supply is calculated as the difference between orders delivered on time and late, divided by the total number of orders. It is an important KPI to evaluate the reliability of a supplier.

Downtime

The downtime in proportion to the operating time consists of the ratio between the time in which the production and supply chain lines are stopped and the time in which they are operational. This KPI is a direct indicator of the availability of resources for production. A low value indicates an efficient use of the production equipment. On the other hand, a ratio of 0.5 indicates, for example, that the production lines have been interrupted for half the time.

Productivity per employee

This KPI shows the areas with the highest return on investment and allows analysis at multiple levels such as company, department and production line. It is calculated by dividing revenue by the number of employees.

Inventory turnover index

The KPI that indicates the rotation of materials in stock is linked to valuable financial and real estate aspects. This is a useful indicator since the spaces of the production area should be allocated as much as possible to the production functions and should not be used to store extra materials and components. The inventory turnover index, or inventory turnover index, indicates the number of times a given product has been completely renewed within a warehouse, and all this over the period of time considered (which can be a year, a month, a quarter and so on). Thanks to this indicator, management is able to understand the efficiency of the efficient supply chain. The higher it is, the more efficient it is, but typically a turnover that can be considered good is 30 days or less.

Inventory quality

It consists of the time or money spent to repair a product due to the quality of the materials used to make it. The KPI can be calculated by supplier, by product category or as a percentage of defective materials compared to good materials.

What KPIs are available on CyberPlan?

Very often it is possible to monitor KPIs directly through production planning software. As in the case of CyberPlan, which has a dashboard with all the typical KPIs for good planning, such as service level, efficiency, missing, lead time. The peculiarity of CyberPlan is that it has as standard all those that are needed, but it also provides the possibility of making configurations that can include the KPIs most relevant to the specific needs of a given company. In addition, in addition to the KPIs, there are also alarms. Get expert advice.