The importance of visualization and more specifically of a visual program, lies in the fact that it is able to give transparency to all your information literally at a glance. The addition of colour increases the effectiveness and immediacy of communication and this also applies to the planning and scheduling systems of production processes. In contexts where there is a large amount of data to manage, where scenarios are constantly changing and where readiness, interpretation and identification of problems are needed, colour can make the difference in understanding a production plan and future scenarios.

Analyse and identify production issues

The benefits of color within a visual program are many and such that it may be difficult to say that you have achieved the best result, without the use of color. This variable is so fundamental and present in what we do every day that we often take it for granted but its importance is such that it must be thoroughly analyzed and understood.

Color increases visibility on business programming and allows it to be effectively modified more quickly, thus achieving effective results more immediately, this is because it adds an element that can be understood instantly and that adds information to the data present in the Advanced Planning and Scheduling software. It is therefore evident that a good APS must be equipped with effective graphics and this also with regard to the colors present in the windows, graphs and KPIs in order to make the decision-making process easier.

The use and importance of color in the life of the human being is so long and rich that it deserves a deepening in itself, here we intend to analyze its use for a more effective planning and scheduling of production.

The role of colour in production planning

Color is used with different functions within a production planning and scheduling program, however it can be grouped into three main functions:

- Colour as an aesthetic element. Different colors can be used to create a pleasant virtual work environment that is easy to work with.

- Color as meaning. Colors can be used to communicate certain messages, in addition to other aspects. Thus, a triangle that indicates the delivery date of an order within a calendar can easily be indicated with the color green or red, depending on whether the date meets the customer’s requests or not. A use of this type allows to increase the understanding of often complex and articulated production plans. Our brain recognizes certain colors automatically with very precise meanings. Red often means an alarm, hazard, or stop, yellow a warning, and green a permit or green light. For this reason it is important and useful to use the right colours within a production programme.

- Colour as information. When representing information, colors allow the planner to make crucial decisions effectively faster.

Understanding the immense value that color can bring to a production schedule is certainly the first step to take to effectively use this aspect. However, effectively using colors in planning and scheduling requires not only the ability to recognize the values they bring, but also the ability to recognize the right amount of colors present. In fact, it is necessary to carefully avoid using an excessive amount since too many colors present on a plane create as many problems as the absence of colors.

The color palette used in CyberPlan has been specially designed for the daily use of the software, the result is a harmonious and coordinated set of pleasant colors that signal critical or virtuous situations when needed.

Recognize critical issues in CyberPlan

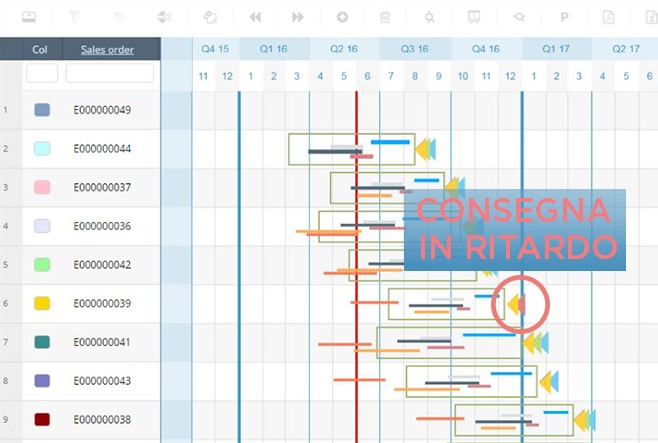

In the development of CyberPlan, great attention was paid to the use of visual indicators that can immediately communicate the potential occurrence of undesirable situations. For example, in the view of sales orders you can immediately recognize if one or more of the sales orders will fall behind the promised date, viewing it in advance so that you can make reliable decisions to improve the On-Time-Delivery. In the screen below we see a series of coloured indicators: the scheduled delivery date (red triangle) indicates that the order will be delivered late than the date requested and promised to the customer. It is then possible in CyberPlan to explore the data by investigating the reasons for the delay (loading of resources, missing materials) and try to remedy it.

All this means that color is not only useful for planning and scheduling, but is now a mandatory element for programming that wants to be effective. What is now established is that a correct use of colour makes the difference in the effectiveness of the scheduling process.

Ready to see how color makes a difference?

Request a free CyberPlan demo to see firsthand the effectiveness of a smart use of color within the most widely used APS workspace by manufacturing companies.

{{cta(‘ab85071a-d654-4295-bbad-b8e8302eeff7’)}}