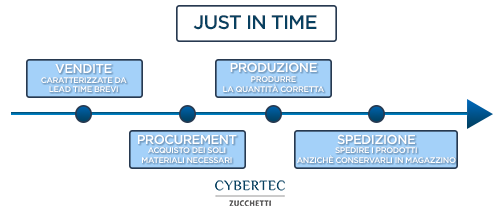

Just In Time production involves carrying out only and exclusively what the customer requests, in the times and quantities requested by the customer. Indeed, this is the dream of every production manager: to be able to have a production system so flexible and elastic that it adapts at all times to demand, both as a mix (number of items) and as a volume (quantity).

Whatis Just in Time in production management

Just In Time (also known by the acronym JIT) is a management model born in the production field and that over time has also incorporated aspects related to logistics. Today when we talk about JIT we can refer to a broader set of concepts that are part of the Lean philosophy. Just In Time, which means “just in time” in Italian, is therefore a production technique linked to the management of stocks and inventory that allows you to minimize waste of resources and renew items according to demand. Founded in the 1950s in Toyota’s automotive factories, Just in Time production then spread around the world and contributed to the spread of the Lean philosophy.

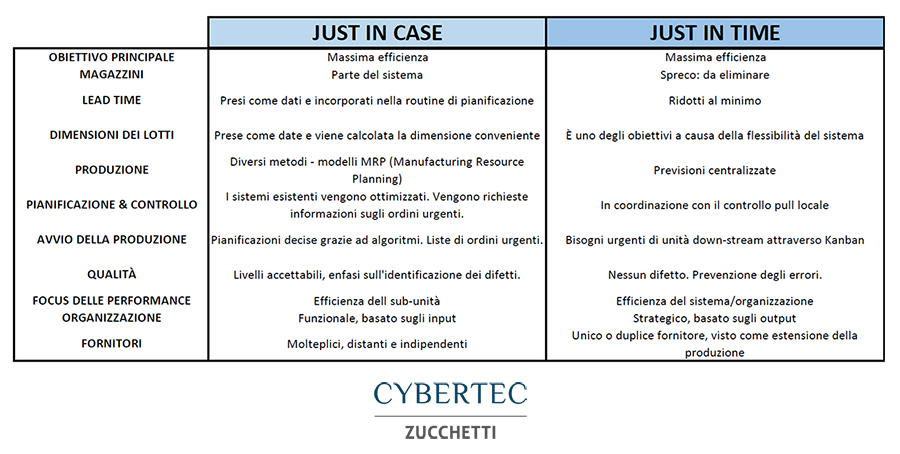

The JIT management model is based on the pull logic that reverses the traditional production scheme and plans to send into production only the products that have already been sold. In short, if applied scrupulously, it allows only the quantities of products actually requested by customers to be prepared in a short time.

The history of Just In Time management

The JIT method originated in Japan and its introduction as a methodology/technique/work philosophy is generally attributed to the Toyota motor company. It is a mentality/way of looking at a production system that is clearly different from what was carried out until its introduction.

In particular, within Toyota, Taiichi Ohno is commonly credited as the father of this working method. The origins of this method are attributed to the historical period that Toyota faced after the Second World War. At that time, the Japanese automotive sector produced a ninth, compared to the American one, and Ohno realized that American manufacturers made the best use of the economic lot (also known as economic order quantities or EOQ), according to which it was better to produce a batch or predetermined quantity of a certain piece or product, before moving on to another. Ohno thought that instead of adopting this method it was better to focus on eliminating waste. In the system he envisaged, waste was eliminated thanks to:

- just-in-time – products move through the production system only if and when they are needed;

- autonomation – automate the production system to include inspections only when a defect is automatically detected, following which the system would stop and not proceed until it is resolved.

In this system, the inventory (or stock) of materials is considered a waste just like having to deal with defects. For Ohno, the waste was in terms of time, resources and materials. He identified a number of causes of waste that needed to be eliminated:

- overproduction: greater waste of resources than necessary

- time lost waiting: time lost such as the worker waiting for the colleague to pass him a piece to work

- transport/movement: waste such as that related to the transport of pieces within the plant

- processing time: processing time longer than necessary

- inventory: waste associated with keeping materials in stock

- defects: waste related to defective products

Toyota also changed the layout of its factory, to eliminate the need to move work products from one work centre to another.

To control the production and flow of items, Toyota introduced the kanban method, which is essentially information about what needs to be carried out and can consist of a card on which the worker finds indications on what to carry out, which pieces to collect and which to produce.

Another aspect of Toyota’s production system is the reduction of setup times, for which the machines and processes must be specifically re-engineered.

As for the history of JIT, Toyota itself managed to use kanbans in its own company in 1962, ten years after the introduction of this system, also due to the difficulties related to the development of techniques.

In Western countries, JIT had a concrete impact only in the late 1970s and early 1980s and was also referred to heterogeneously at the time with terms such as “stockless production” used by Hewlett Packard. Such systems were created based on informal documents as the first detailed books on the subject date back to the late 1980s.

The advantages of Just in Time production

Just In Time production allows companies using this methodology to achieve great results:

- Reduction of the risk of product obsolescence, as we always work with minimum stock levels;

- Increased capacity to react to any fluctuations in the market;

- Strong reduction of preparation times in the warehouse. Reducing preparation time allows the company to increase productivity and efficiency while leaving time to devote to other areas that may need improvement;

- Improving the flow of materials from the warehouse to the shelves. Making workers focus on specific areas allows them to process the goods quickly and not get tired doing too much work at the same time;

- Production intervals are short, which means that manufacturing companies can quickly move production from one product to another;

- Cost reduction thanks to the fact that JIT minimizes the need for warehouses and therefore the costs related to storage. The goods in stock are reduced and the costs related to their conservation are reduced;

- In addition, companies spend fewer resources on raw materials because they can only buy enough to produce the recorded sales orders and no more than necessary.

Since stocks are interpreted as a cost to be eliminated, it is advisable to avoid as much as possible the expenses deriving from an accumulation of raw materials (or other materials and products) that, when they remain in storage, do not generate value.

To apply the Just In Time methodology, therefore, it is necessary to intervene on the upstream phases and meet some fundamental requirements.

The Disadvantages of Just in Time Production

However, Just In Time inventory systems present potential problems for supply chains. If a raw material supplier has a problem that creates an interruption that prevents the timely delivery of goods, this can create cascading problems over the rest of the production process until it is interrupted. In the event of a sudden and unexpected order of products, it is possible that the delivery of finished products to customers may be delayed.

Unfortunately, the JIT inventory system can cause some problems for companies using this method, as happened to Toyota in February 1997. Following a fire at a plant of the Japanese supplier Aisin, in fact, the production capacity of valves for Toyota vehicles was significantly reduced. Since Aisin was the only supplier for this component, its stop of several weeks caused Toyota to stop production for several days. This also caused a cascade effect, where other Toyota parts suppliers had to temporarily stop their production processes as the manufacturer no longer needed their products during that shutdown period.

Who is involved in Just in Time production

The Lean philosophy and in particular Just In Time production involve different roles and departments within a manufacturing company. Being methodologies that concern the type of production and its management, they mainly involve the following roles and professional figures:

- Head of Supply Chain/Supply Chain Manager

- Production Manager/Production Manager

- Plant Manager/Plant Manager

- Head of Planning/Planning Manager

- Planners/Planners

The requirements of Just in Time production

The Just In Time production model imposes certain conditions that it is good to respect from an organisational point of view. Below we briefly list the main requirements to be met:

- The flow of information must be fluid and constant. Excellent coordination between suppliers, manufacturers and customers is necessary;

- It is essential to prioritize supplier reliability, and to put the purchase of large quantities of products at advantageous prices on the back burner. This may involve re-planning procurement processes and supplier selection criteria.

- It is appropriate to consider the implementation of technologies that allow accurate forecasts to be made and that are able to cope with sudden increases in demand.

The requirements listed above bring out all the complexity of a model that relies on the ability to adapt production to demand. In many cases, especially when the latter fluctuates more than expected, the production sector may end up under pressure, as it must always be ready to provide resources in a short time.

But how can JIT be applied concretely in a warehouse and what are the most suitable systems for storing materials? Below we provide a quick overview of the elements that distinguish the warehouse oriented to the Lean management model. First of all, you need to have a layout designed for lean logistics. The Just In Time warehouse above all seeks agility, which is achieved thanks to the correct mix of area organisation and storage solutions. Therefore, it is advisable to design the warehouse taking into account both the storage needs and the speed required by the JIT. In order to move goods quickly, it is good to simplify operations and to achieve this there are several ways:

- Reducing the distances that operators have to travel and/or installing conveyor belt circuits;

- Building automated warehouses that can take up less space and reduce the storage time of low-rotation products. For products with a high turnover index, which must be accessed directly, it is advisable to opt for shelves suitable for picking;

- Through the strategic positioning of warehouse entrances that must facilitate the reception and shipping phases of goods that normally travel in large quantities and are contained in small packages;

- Automatic systems facilitate the loading and unloading of goods, a fundamental aspect of JIT.

We have said that just in time is the result of the choral work of all the actors in the supply chain. In this regard, departmental software are the most suitable tools to control what happens along the supply chain and in the warehouse.

Just in Time Production Examples

If we look at concrete examples of the application of Just In Time, we cannot fail to mention Toyota Motor Corporation, a company famous for its Just In Time inventories, which orders components only when it receives new orders for the sale of its cars. Although this method dates back to the 1970s, when it was implemented by Toyota itself, it took over 20 years to perfect it. The terms Short-Cycle Manufacturing (or SCM), used by Motorola, and continuous-flow manufacturing, used by IBM, are synonymous with the Just In Time JIT system.

Improve your work by reducing effort

Every professional wants to work using suitable tools that allow them to improve the quantity and quality of output. Planning managers, Supply Chain Managers and department managers can now use software solutions designed specifically for their daily tasks and assignments. Ask an expert how you could increase performance, reducing effort and effort to focus on higher value-added tasks.