AP Automotive Products, an automotive company in continuous expansion, had the foresight to move from manual production planning to advanced management through an APS (Advanced Planning and Scheduling software). Engineer Ilaria Romagnoli, Supply Chain Manager, tells us the story of the company that has been governing production planning and scheduling processes with CyberPlan for over fifteen years.

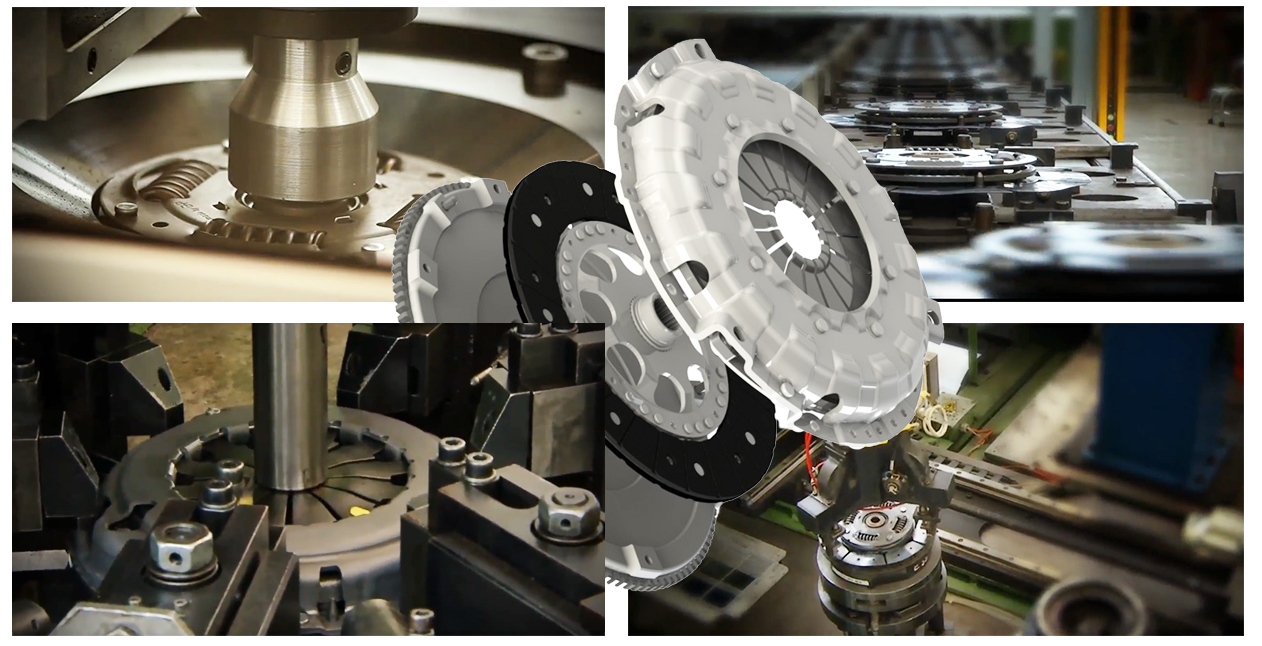

Automotive clutch production planning and scheduling

AP Automotive Products, a Raicam group company, is a leader in the production of clutches for cars, trucks, motorcycles and tractors.

Maintaining Control in a Growing Company

AP Automotive Products had the foresight to move from manual scheduling to APS, advanced scheduling and scheduling software. The need to change the tools used to plan production was born from the strong and continuous growth of the company, both in terms of products and turnover.

Before CyberPlan, in fact, the assembly gantts were calculated using Excel sheets only, within which an operator had to enter codes and quantities and then manually color the boxes in order to simulate the hours of work necessary for production. This file was difficult to share and required a continuous update of the boxes that were added, removed and colored manually.

The calculation of the missing components was also carried out manually by an operator who had to check the bill of materials; within the bill the same component could in fact appear simultaneously on different batches, so it was complicated to identify the components. Unlike CyberPlan, in fact, AS400 does not take into account all production commitments.

Both the production planning and the assembly gantts were operations that had to be speeded up and simplified and at the same time it was necessary to reduce errors and increase the depth of analysis. All this while the company continued to grow.

Integrated planning and scheduling

AP Automotive Products has foresightedly identified the APS (Advanced Planning and Scheduling software) tool as the best response to the challenges ahead.

CyberPlan was thus installed in 2001 and began to bring its benefits immediately after the installation phase. The software solution for advanced planning and scheduling has been so adapted to AP’s business reality that today the MRP (Material Requirements Planning) is calculated together with procurement and subcontractor accounts. The time horizons covered range from the three months of planning the production plan to the daily schedule.

When AP Automotive Products took over an English company, it was decided to migrate the latter to the management system in use in AP and to integrate the plant with the planning carried out through CyberPlan. This has led to numerous advantages as it has allowed the two companies (previously in a customer-supplier relationship) to bypass the entry of orders and leave the management of these aspects to CyberPlan.

Ease of use, communication and responsiveness to the market

AP Automotive Products today carries out both long-term planning and detailed scheduling of its clutch production, thanks to a single tool: CyberPlan.

The benefits that the company had were immediately visible with a fast and simplified production planning. In terms of communication, the APS tool has made it possible to facilitate meetings between management and the planning and production departments, thanks to the fact that all MPs information can be collected and exported. In addition, the communication between the purchasing and sales offices in England and Italy can communicate directly with each other thanks to the fact that they no longer have to place the related orders.

CyberPlan also supports customer service by allowing you to analyze the situation, in case of arrears, to send reminders to internal departments or suppliers. Today, when a customer requires extra production, AP can also carry out simulations in a fast and organized way, giving certain answers in a short time, thanks to the fact that it takes into account all the constraints, giving the certainty of taking into account all the problems and overlaps that could exist.

“In AP Automotive Products it is now possible to carry out in-depth analyses, from production to logistics, and export the results in tables, allowing you to take into account all the data master data, useful for data analysis.” Tells Eng. Romagnoli.

AP’s considerable and continuous business growth over the last few years has led to the development of many new products, increased turnover and the acquisition of new productions. In this context of expansion, CyberPlan has helped the company to manage growth and keep warehouses under control, rationalizing their growth, improving timing and planning accuracy, despite the considerable increase in the amount of data.

The most popular features:

- Ease of searching for information;

- Easy analysis of information, both in aggregate and disaggregated form;

- Depth of analysis;

- Visibility of data;

- Export of data for further analysis;

- Extremely short planning times;

- Planning speed.

Specialised advice and assistance

“In addition to the CyberPlan tool, which allows us to keep business competitiveness high, another strength of Cybertec is represented by the consulting and assistance teams, which are always present and quick to respond. These are people who stand out for seriousness and punctuality, something they tell me is not so obvious to find, elsewhere.”

AP Automotive Products

AP Automotive Products, a Raicam group company, is a leader in the production of clutches for cars, trucks, motorcycles and tractors.

The company has always paid great attention to the high quality and safety of its range of products and services, thus managing to become an expert partner and trusted supplier for the Automotive industry around the world (some of the company’s customers are: Aston Martin, CNH, Fiat, Ford, Iveco, Land Rover, Lotus, and Volvo). The trust that customers recognize in the AP product is the result of over a decade of collaboration with these leading companies in the automotive sector and is concrete proof of the validity of the products as well as the absolute professional capacity of its collaborators. The products made by AP Automotive Products are used both as first plant and as original and after-market spare parts. The collaboration with the manufacturers goes all the way to the creation of products that are as personalised as possible.

The Raicam group has several production plants, which are located in England, Italy and India.

CONTACT US

Contact a Supply Chain expert to learn more about APS software and the benefits it can bring to your business, call us on 040/898111 or fill out the form.