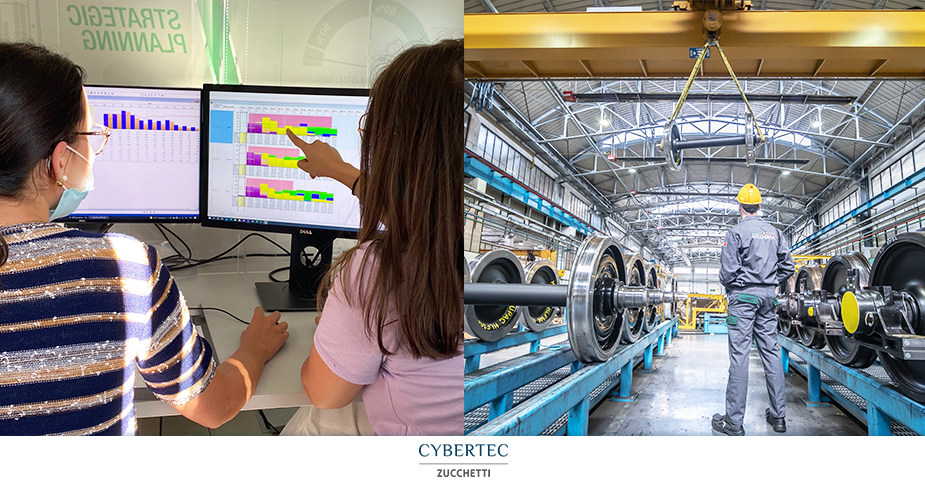

Lucchini RS is an important Made in Italy company specialising in the production of rolling stock for trains, trams and metros. The management of the Brescia company, with the aim of growing and remaining competitive, had the great merit of understanding the importance of the planning process. And it is precisely thanks to this intuition that the Lucchini RS production planning department has evolved over the years, moving from a purely operational task to an element with a strategic role. The company thus began to prepare the Sales and Operations Plan on a monthly basis, paying greater attention to a medium and long-term time horizon.

Marco Mariotti, Strategic Planning Manager of the Railway division, tells us about the journey that began in 2006 and that through a series of stages has led to this incredible change.

Simplify the planning of non-standard products

Lucchini RS made a mistake, common to many other manufacturing companies: it planned production through Excel files in the management system. “The operation to obtain all the necessary information was quite laborious, since it was necessary to make extractions from SAP that then had to be crossed, and the process had to be repeated in full every time it was necessary to update the information” says Mariotti. In essence, it lacked a tool capable of collecting and converging all the useful information and data, without having to resort to numerous operations to extrapolate the data and to unite them.

Adding complexity to the scenario was also a peculiarity that the company was facing, i.e. products that are not standard. Lucchini RS in fact produces wheels, axles, wheelsets for railway use, and each project has its own type of wheel, because it is produced according to the characteristics of the train on which it will be applied. This involves different degrees of difficulty and different project lead times. It was therefore important to have a planning tool that took into account the different complexities of the products.

A step-by-step journey to evolve the planning process

The Lucchini RS journey began with careful software selection, which led to the choice of the CyberPlan APS. CyberPlan’s ability to transform and adapt to the needs of those who use it was decisive, a characteristic that played a crucial role in the evolution of the planning process and in the growth of the company, so much so that today it is an indispensable tool for operational and strategic decisions.

As mentioned, Lucchini RS’s journey has been divided into several stages. The initial priority was to set up CyberPlan to import and analyze data related to production cycles, times and machines, so as to have all the information necessary for planning in a single container. Another important stage was that relating to the control of the production process through simulations of finished capacity workloads. The next steps included the monitoring of production progress, supported by an effective Shop floor control system, the sharing of machine schedules in the various departments, the development of balanced production plans, the sharing of MPs with production lines on a web platform and the automation of KPIs on MPs plans.

“The transition to Sales and Operations Planning processes allowed us to see in advance and quickly the workloads of the different types of products. This allows the appropriate actions to be implemented in time in order to re-balance workloads, through appropriate commercial actions, and capacity, through the remodulation of plant utilization rates. Thanks to Manufacturing Forecasting, then, the production of certain components is analysed starting from the data history, in order to reduce the production lead time and reach the customer first “, says Mariotti.

Multi-product planning in the sign of reduced lead times and WIP

With the right tools, the Lucchini RS planning team was able to effectively solve the problem of managing the production of multiple products. In fact, CyberPlan allows you to carry out a multi-product planning, but not only. It is also possible to simulate production plans based on the optimal queue of work centres considered critical, and this has allowed WIP to be controlled and reduced. Outsourced loads are also monitored, processing MPs for suppliers. In general, the efficiency of the processes has been improved, in fact, starting from the analysis of workloads, in case of overloads, alternative cycles can be identified on other internal machines or on suppliers, whether they are intra-group, Lucchini RS has a network of international or external plants.

Other main results concern the improvement of delivery performance and customer service, the reduction of lead time, the possibility of having all planning information available in one place and, finally, the possibility of carrying out finite capacity simulations.

CyberPlan also improved the flow of information between departments. Through software, in fact, balanced production programs easily come to the attention of the production that validates them and makes them available to the departments.

Lucchini RS, one company and two divisions

The Lucchini RS group operates in the steel sector and is active in two divisions: railway and forged components with drawings and castings. The production of high-end railway components includes wheels, axles, high-speed mounted halls (locomotives, passenger trains, trams, subways), meeting the demands of customers all over the world. The production of forgings with designs and castings for various application uses includes electrical generators, oil and gas, offshore platforms, cement processing, industrial plant engineering, steel and iron production plant engineering or naval transport. The group also produces a wide variety of tool steels.

The Lucchini RS group operates in the steel sector and is active in two divisions: railway and forged components with drawings and castings. The production of high-end railway components includes wheels, axles, high-speed mounted halls (locomotives, passenger trains, trams, subways), meeting the demands of customers all over the world. The production of forgings with designs and castings for various application uses includes electrical generators, oil and gas, offshore platforms, cement processing, industrial plant engineering, steel and iron production plant engineering or naval transport. The group also produces a wide variety of tool steels.

Lucchini RS offers safe, reliable and high quality solutions operating with advanced and efficient technologies, thus promoting the sustainable progress of mobility and industry.

Curious? Learn how to improve your planning

Today you can contact a planning and scheduling expert, ask them your questions to resolve any doubts or have your curiosities answered. Learn how you can improve the tools and processes in your planning department to achieve superior performance. Contact an expert now.