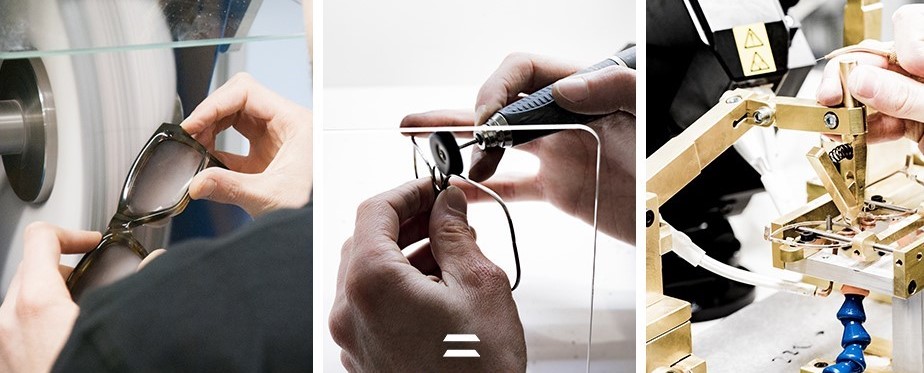

Opened in early 2018, Manifattura Thélios is the result of a joint venture between LVMH and Marcolin. Created with the aim of combining the skills of the two groups and pursuing the vision of both about the future of eyewear, Manifattura Thélios wants to be the reference in customer service both in terms of product availability on the market and the quality of the products made, thanks to the combination of advanced technologies and know-how.

Mattia Dazzi, Production Planner Manager at Thélios, tells us how the young Venetian company has decided to organise production planning and scheduling processes in order to support company growth and success.

Thélios’ goal: a benchmark level of service thanks to versatility and flexibility

Thélios was born by combining the skills of the eyewear world of Marcolin with the experience of the luxury leader LVMH as a new house focused on eyewear. Thélios’ goal is to be a leader in the production of luxury eyewear and to provide the best possible service to customers, both in terms of relationship and product availability.

Since its inception in 2017, the Venetian company has therefore focused its attention on allowing the achievement of the best level of customer service, paying particular attention to the containment of production lead time. In this sense, it was useful to increase the capacity to evaluate constraints, production plans and line balancing.

To achieve these goals, Thélios has focused on innovation and standing out by taking all the know-how of eyewear and taking it in a lean direction, both in terms of supply chain and in terms of production.

Driven by these aspirations, the Venetian company has sought the best solution on the market that would allow an advanced management of production processes and that would have at the same time characteristics of flexibility and versatility such as to adapt to the new company reality and follow it in growth and in the years to come.

CyberPlan to plan and schedule a growing production

Thélios has thus chosen CyberPlan, Cybertec’s advanced production planning and scheduling solution, since the start of production. The choice was made quickly because the alternative solutions evaluated by the company did not guarantee the same possibility of customization or the same depth of analysis guaranteed by the Cybertec solution.

In selecting the best planning solution Thélios also benefited from Marcolin’s experience. The countless years of use of APS by the Venetian company have in fact led Thélios to consider the CyberPlan solution the best able to follow them in rapid growth while maintaining the focus on performance and service level.

The aspects that were considered to be the strengths of CyberPlan were its versatility, the possibility of configuring the tool in a fairly strong way, which allows it to be adapted to the needs of the business.

CyberPlan was chosen for all planning operations, from Sales and Operations Planning to detail scheduling and the job set.

A fast project and robust integration with SAP

The adoption of CyberPlan and its integration into Thélios happened quickly. First, the data transfer structure was created that allows CyberPlan to use the data from the SAP ERP and then return the plans drawn up to it.

Every day information such as sales forecasts, sales orders, production orders and master data are processed by CyberPlan to develop plans and simulations extremely useful for production planning. These analyses and processes are then sent to SAP, in a relationship of close mutual communication.

Subsequently, some aspects developed at the specific request of the company were customised, always bearing in mind the ultimate goal of quickly and effectively achieving the company’s objectives.

Integrated planning to make quick and effective decisions

Thélios is now able to carry out specific calculations and reasoning that SAP ERP did not allow to be carried out: from MRP (Material Requirements Planning) calculation to detailed scheduling, passing through the generation of production plans, to stock and backorder analyses, to evaluations about the punctuality of deliveries and feasibility. Cybertec’s solution therefore provides a fundamental help to the planning department to make decisions about the entire production.

Thélios carries out a series of analyses thanks to CyberPlan, among the main ones:

- Sales and Operations Planning;

- MRP (Materials Requirements Planning) calculation;

- Production scheduling;

- Make or buy decisions;

- Decisions and prioritization of certain orders;

- Stock projections;

- Back-order projections;

- Detailed analysis of the punctuality of the delivery of certain orders;

- Analysis for delivery plans;

- Feasibility analysis.

Thélios has found in CyberPlan the tool to manage the entire production process, from the planning of operations for the months to come to the daily detailed scheduling.

The benefits of using CyberPlan

CyberPlan is useful not only for tactical planning analysis and production planning but also for strategic analysis. In fact, the software solution is also used to make decisions regarding subcontractors and inventories, as well as backorder projections or detailed analysis of the timeliness of deliveries.

Another aspect assessed as particularly useful by Thélios is the possibility of carrying out numerous simulations of future production scenarios. In fact, CyberPlan allows you to modify parameters and values, enter orders and modify existing ones without the need to create customised structures. This allows operators to evaluate the possibilities and choose the one that best suits the business context of the moment.

In addition, as a Make To Stock company, the use of CyberPlan is also useful to Thélios for the accuracy of production forecasts as well as the accuracy in predicting the delivery date to the customer. All this allows Thélios to achieve service levels at 2 and 4 weeks that are around 90%.

In a constantly growing and changing company like Thélios, more rigid software would have limited the continuous adjustments and improvements needed. CyberPlan’s flexibility and configurability allow it to adapt very well to a constantly evolving business such as that of Thélios that needs continuous changes, continuous variations and improvements.

Thélios, innovative joint venture between LVMH and Marcolin

Launched in 2017, Thélios is a joint venture that combines the expertise of LVMH and Marcolin, two groups that share the same vision of the future of eyewear. The company has 400 employees worldwide, of which about 200 within the Manufacture. Thanks to the combination of advanced technologies and unique know-how, the Thélios Manufacture constitutes a complete and dynamic production organization that ensures widespread control of products: from the initial creative brief to the 3D design and final realization, through the development of the prototype.

The digital planning solution for manufacturing companies

Numerous manufacturing companies have decided to implement finite-capacity production scheduling software, in order to get the most out of their plants and production resources. The positive aspects of these projects do not stop at the boundaries of the plants but also touch on inter-company and extra-company communication, reaching the purchasing, sales and suppliers offices. Contact a Cybertec supply chain expert to learn more and learn more.