DDMRP is a method to plan and manage the Supply Chain based on demand. Initially this methodology was applied by small and medium-sized companies, and then spread more frequently to larger and multinational companies. To date, thousands of companies have implemented DDMRP, which has become one of the most popular methods among Supply Chain experts. SAP, one of the most popular ERP software, offers a specific functionality to manage the supply chain in a DDMRP perspective. Learn about the benefits of using DDMRP with SAP and which APS to choose for optimal supply chain management.

Whatis DDMRP

DDMRP is a multi-level supply chain planning and management method, which is based on managing inventory reserves through strategically positioned decoupling buffers. The DDMRP combines aspects of Material Requirements Planning (MRP) and Distribution Requirements Planning (DRP).

DDMRP has developed precisely from MRP and represents its evolution. MRP is a production management system based on inventory control. Born in the 1950s, the method was based on a market where the life cycle of products was much longer and confined to local markets, both in terms of supplies and distribution. The main limitation of MRP is that it does not take into account the complexity of the current market, products with increasingly shorter life cycles and a demand that becomes more diversified and personalized. In addition, the Supply Chain is also increasingly variable and populated by a greater number of actors.

A consequence that derives from the inability of the MRP to cope with the volatility of the modern Supply Chain is represented by the so-called “whip effect“, according to which variations in demand are amplified by going up the entire Supply Chain to the suppliers, and consequently the logistics flow undergoes variations that are amplified to the downstream. On the other hand, DDMRP, thanks to the introduction of buffers, disconnects, at least to a certain extent, the different production lines from market trends, absorbing, or in any case softening, the effects of any distortions.

Whatis SAP

SAP is an ERP (Enterprise Resource Planning) software capable of managing all company resources and planning activities. Used mainly by large companies and multinationals, in recent years it has also been adopted to a greater extent by SMEs.

SAP has a modular structure that encompasses the macro-areas where the software allows you to operate (e.g. purchasing, orders, accounting, budgeting, production planning, strategic data analysis). In total there are about 15 modules, each one on its own but at the same time 100% integrated with each other. Each user who works with SAP is specialized in only a few areas and therefore uses only a few modules.

SAP allows you to follow the entire production process by carrying out common operational actions through the software, such as requesting an order, purchasing from suppliers, managing accounting or budgeting. Thanks to its characteristics, the various business areas can be better managed, promoting company productivity.

The benefits of DDMRP with SAP

Using SAP in a DDMRP perspective helps increase the efficiency and optimization of production and procurement plans. Demand-Driven Replenishment (DDR), a feature offered by SAP, helps you plan and manage your supply chain efficiently based on customer demand. Material flows are strategically decoupled and protected by dynamically managed buffer levels, so as to be less vulnerable to disruptions that may occur along the supply chain.

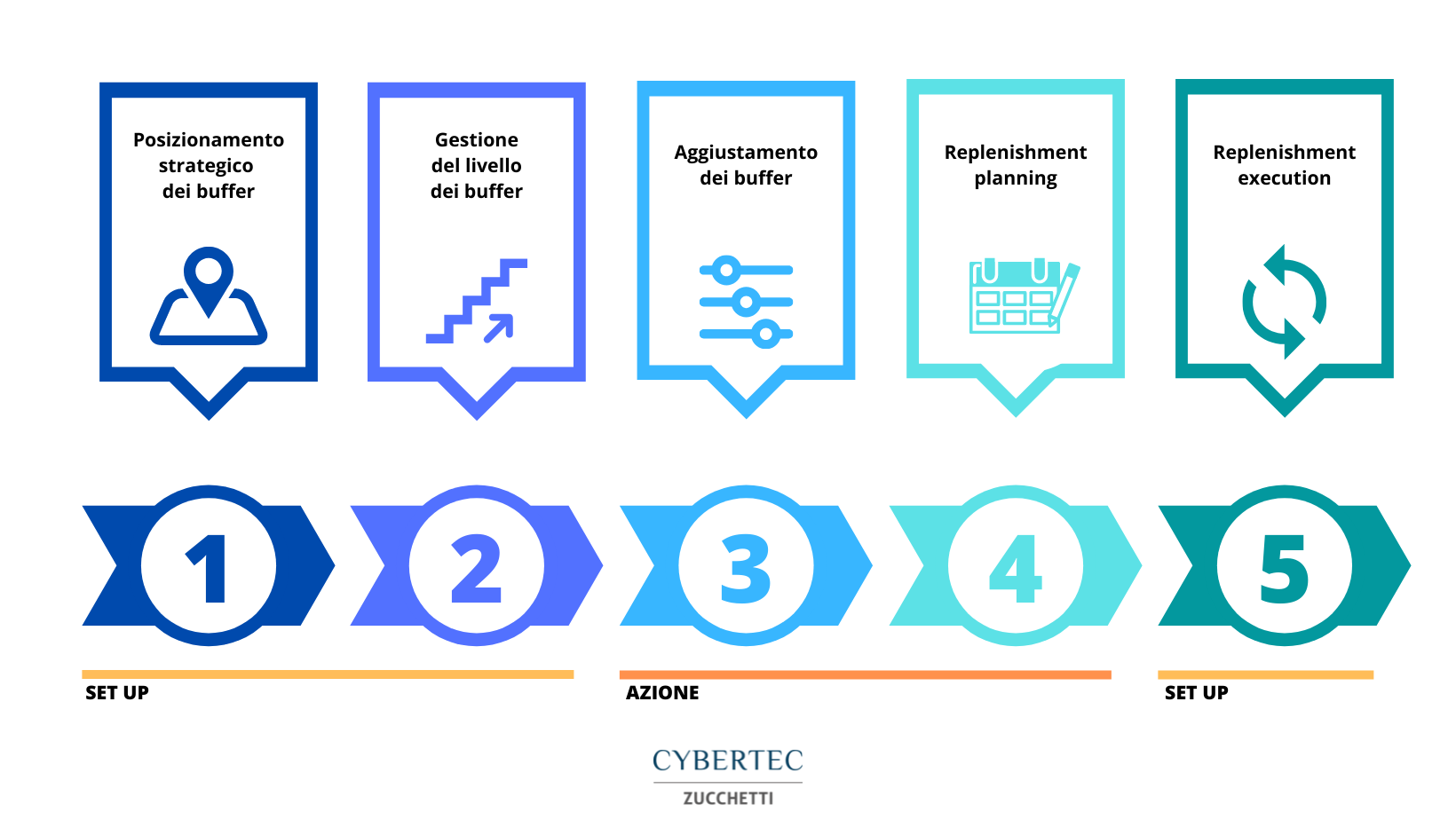

Strategic decoupling and buffers are just two of the elements on which DDMRP is based. Both serve to create independence between processes and stop the whipping effect, mitigating supply and demand variability and reducing lead times. Other elements are dynamic buffer adjustments to stabilize the Supply Chain and demand-driven planning, which allows you to generate supply orders by evaluating actual inventory, stock ordered but not received, and qualified sales orders.

The main objective of the DDMRP is to enable the flow of materials, an essential concept when demand is volatile due to promotions, innovation, shorter product life cycles and competition, and when there is rigidity in supply (long lead times, large batches, capacity constraints…). Two elements that often translate into challenges in terms of service, inventory, speed to market and costs.

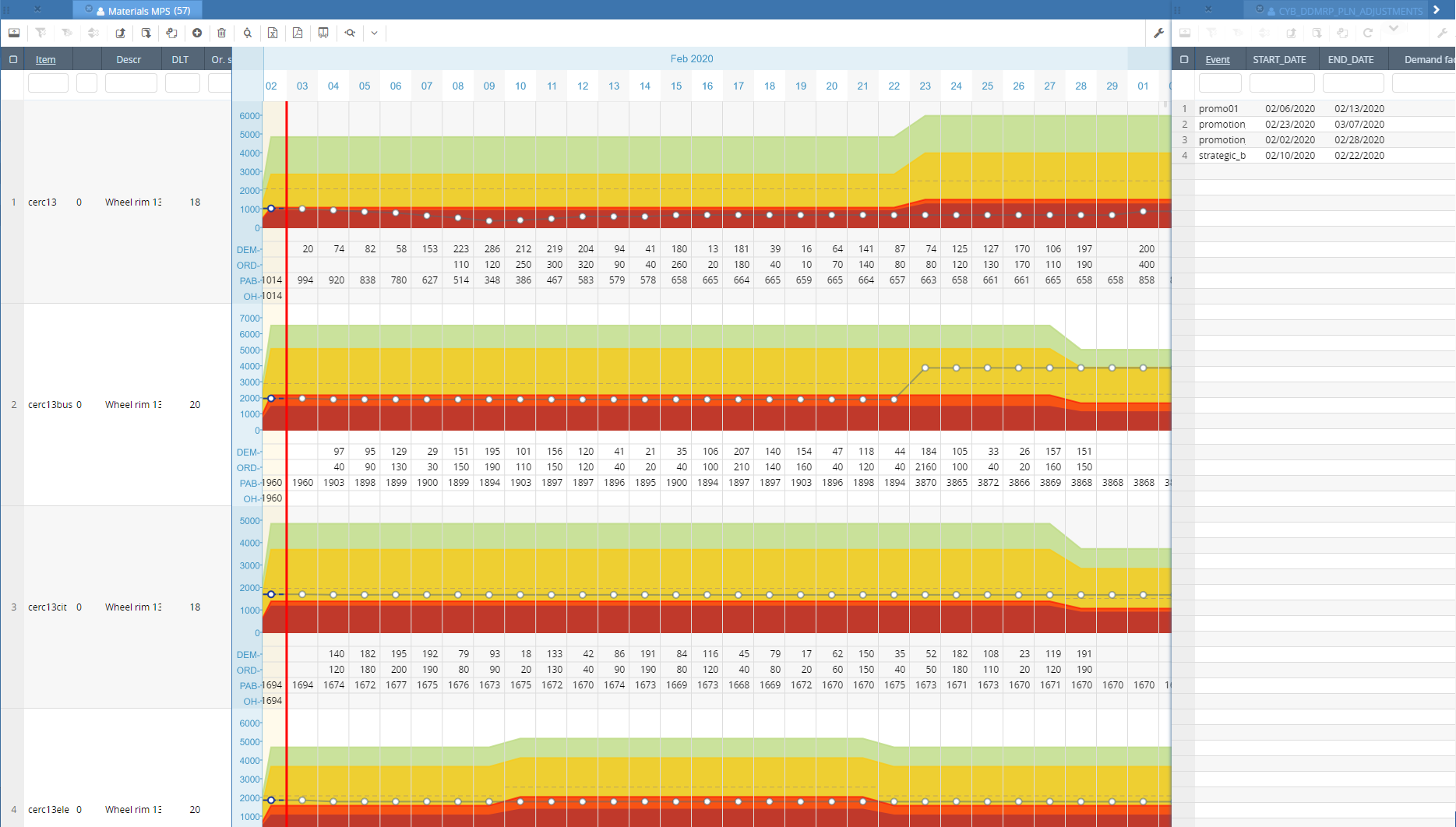

SAP simplifies DDMRP planning by making it more intuitive and accurate. The software allows you to classify materials and products by identifying them as relevant to the DDR and to define the inputs to set the buffers. Relevant products tend to be ranked based on their decoupling lead time within a specific evaluation interval. Products can also be reclassified periodically for the most accurate results possible.

Based on average daily usage, decoupling lead times, buffer profiles, and other factors, different buffer level proposals can be generated to manage safety stock, reorder point, and maximum stock, ensuring products are available when needed. Buffer proposals can be recalculated periodically to keep them up to date and maintain appropriate inventory levels during DDR.

SAP also makes available information sorted by planning priority and useful to replenish on time, avoiding running out of stock and experiencing delays in completing production or sales orders. The ability to view the stock of each product in real time is useful to speed up procurement.

Why use CyberPlan DDMRP

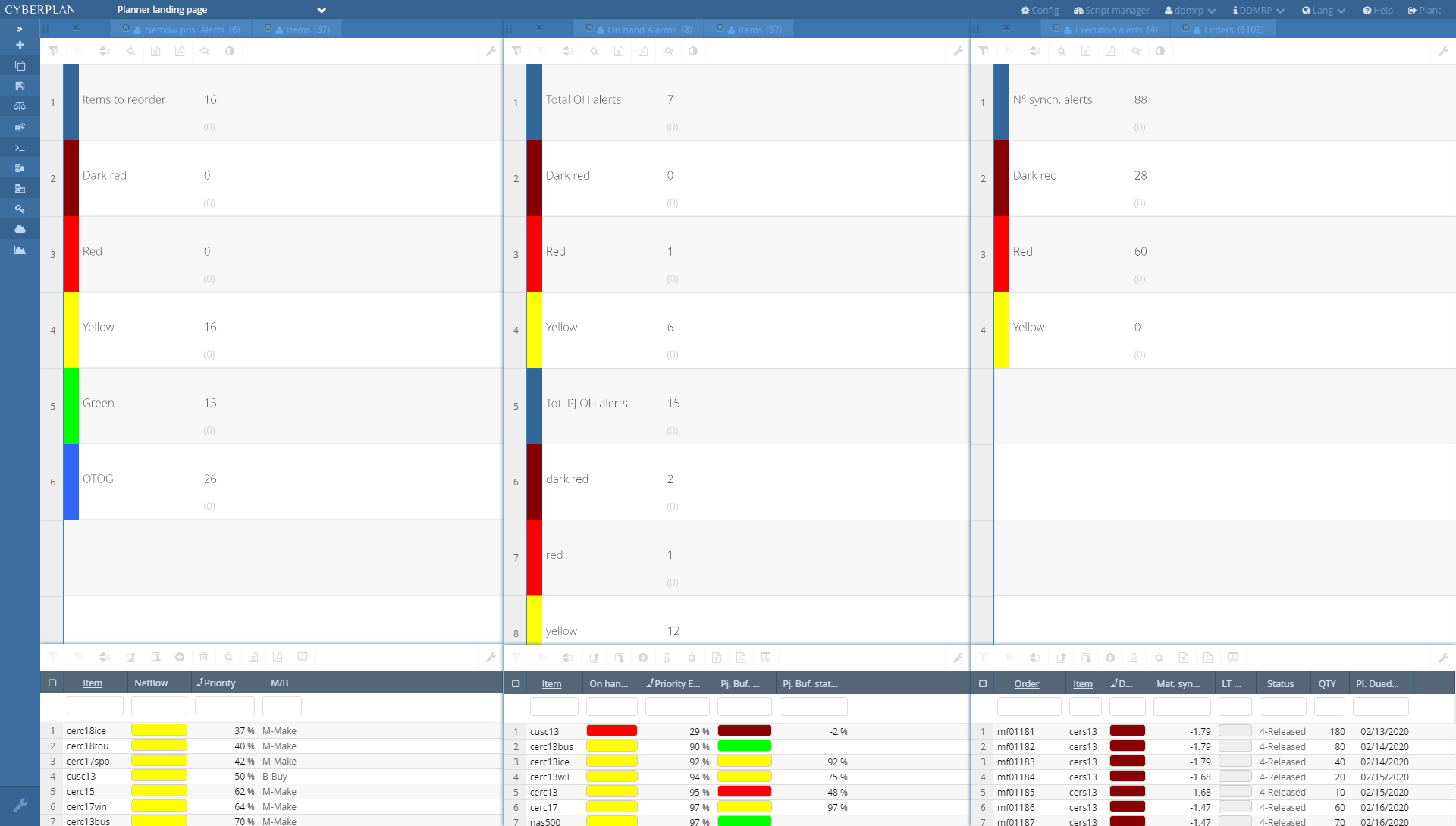

CyberPlan’s DDMRP software allows purchasing and production departments to plan the production and procurement of materials in a precise and timely manner. Planning with CyberPlan avoids interruptions in the production flow and stock outs, as well as excess inventory in stock or obsolescence of materials.

Through intuitive workflows, all the necessary information is available, reducing time and process errors. Dynamic buffers ensure the right amount of stock and it’s easy to prioritize orders.

The solution is certified by the Demand Driven Institute and in addition to integrating with the rest of the CyberPlan suite, it integrates with the main ERPs, such as SAP.

If you want to find out how the right solution can help you, contact a Cybertec consultant.