Even today, manufacturing companies equipped with ERP, to plan and schedule production, find themselves making important decisions on dozens if not hundreds of Excel spreadsheets. And we are talking about decisions that impact production performance and the entire company business in terms of efficiency, service level, warehouse costs and WIP. In many cases, in fact, spreadsheets are also used to create the production plan.

Whatis a production plan in Excel?

A production plan created in Excel is a tool with which companies try to follow the production trend of their company.

This Excel sheet is usually set up to process production data and provide graphs that highlight the values and trends over time of production, waste, rework, productivity, etc., both overall and for individual production lines.

Usually the main page is the one related to the production data, to which all the other pages and tables of the sheet are attached. In particular, the sheet consists of the following pages:

- Production data that contains production data and is designed to be fed with data extracted from the management system, for example Zucchetti’s Infinity,

- Control of the production lines for the daily analysis of the lines,

- Waste and productivity,

- Trends.

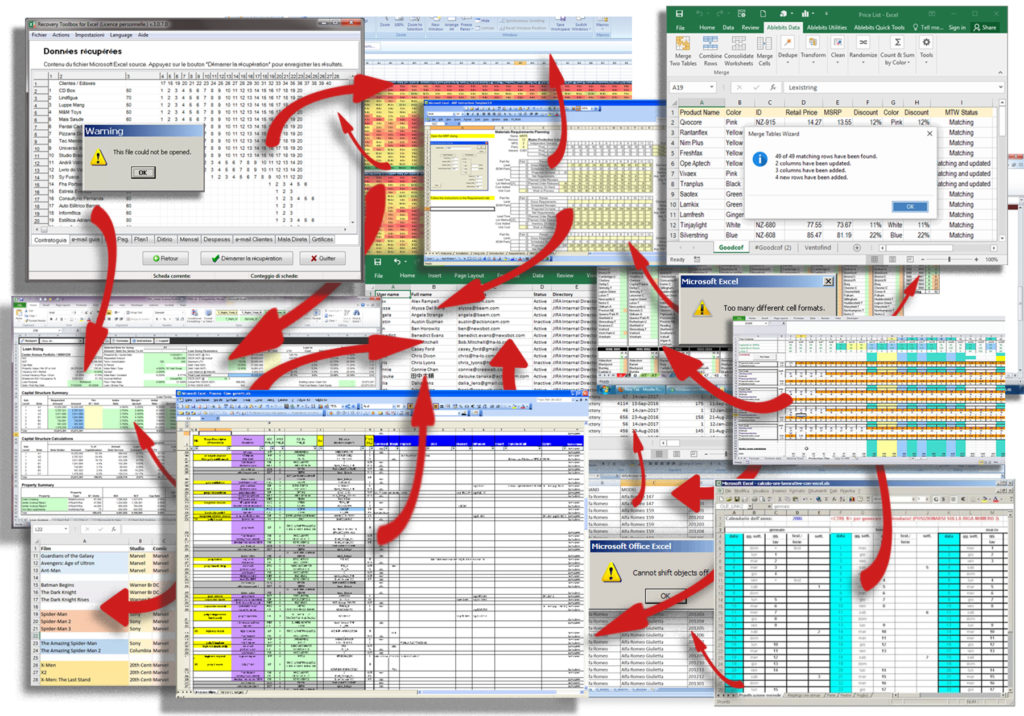

So let’s see what are the risks of planning using spreadsheets:

1) Simple changes to the plan create laborious changes to the Excel file

In Excel, even the simplest variations (such as changes to dates) require a consequent deletion / addition of new cells, variation of colors, merging /disjoining of cells, and other small changes, as appropriate. Planning and scheduling become laborious to the point that large changes or constantly changing plans can absorb even hours of work by the planner and without the assurance that the Excel output is correct.

Temporary work situations (and more) are often downplayed as “unique situations” when the reality is that such occurrences occur continuously in the life of each company. The solution therefore lies in exploiting a tool that allows you to be flexible and make changes in a simple and controlled way.

2) The information is divided into silos of the different departments

The use of Excel leads to the creation of a multiplicity of files for different users, departments and locations as silos isolated from each other. Connecting and merging these silos when you need to get an enterprise-wide overview takes a lot of work in terms of energy and time. This isolation of information combined with the rapidity of today’s data changes leads to a continuous state of emergency and the creation of management reports that are obsolete from the moment of release.

It is therefore necessary to provide access to the same production plan to several users in your organization through a centralized system, offering operators the possibility to simulate the impacts for the different departments while maintaining the original version and the overall vision. Once the changes to the data lead to a plan that turns out to be better, this must be easily shared and made visible to everyone in real time so as to allow the entire organization to achieve the best, functioning as a cohesive unit.

3) Production planning in Excel is less efficient

An extended and/or disorganized Excel file system makes it extremely difficult to search for information contained within a large number of files and does not allow all the data to be processed in the necessary level of detail. The consequence is the expenditure of an enormous amount of time to obtain results that nevertheless remain imperfect. If it is not possible to identify the best plan in time, or if that step is skipped because it is a task that takes a long time for the operator, the advantage that can be obtained is lost and a lot of time continues to be spent on discreet results.

Everyone invests a large part of their time in work; not being able to maximize the results is therefore a waste. What is needed is a simple and fast functionality that allows company-wide searches in the blink of an eye, transforming all the data already present in the management system into easy-to-use information. Data is always present within companies with ERP, the difficulty is to exploit all the data by processing it into information to be used to make safe decisions with clear impacts at all levels and departments. When the results are processed instantly by calculating all the factory constraints and the interests of the various departments, precious time is not wasted and a high level of efficiency is easily achieved, greatly reducing production costs.

4) An Excel production scheduler makes it difficult to make predictions

Many companies completely lack the ability to dynamically forecast demand and production capacity. Excel was not created for this process type. These companies therefore have a limit in generating regular or ad hoc reports for different levels of management, or waste a lot of time and effort because they have to do it manually. In addition, all data must be copied and re-copied manually with a huge risk of error. Lack of forecasting costs companies a huge competitive disadvantage.

The solution to this problem is to strengthen your company thanks to the business intelligence you need to predict the use of capacity and resources. This allows you to adapt to changes before they arrive, take advantage of new market opportunities and always stay one step ahead of the competition.

5) Excel confines the exchange of information to a file-based scheduling system.

It is not possible to generate a user-specific view of the information from a spreadsheet. It is therefore necessary to distribute the information in individual files, one for each user. This means risking huge misunderstandings and communication problems on a daily basis.

To have a cohesive company you need to centralize data at the enterprise level in one place while allowing users to access information that relates to their specific tasks and needs, whenever they need it. The end result is a saving of time, energy and improved communication.

{{cta(‘c15e481e-a69f-4941-8c6a-0b4cd5a71b2d’)}}

Conclusions:

Planning should work for you… not the other way around!

It is common to continue to use cumbersome tools and systems when you are not given time to evaluate new solutions or implement them in your organization.

However, when you are realistic about the energy consumed and the inefficiencies caused by programming using Excel, you realize that it is not possible to persevere in the use of these spreadsheets. The problems generated by these systems that require the constant work of the operator (isolation of information in individual files, inability to make forecasts, inability to achieve the optimal plan and time required by these spreadsheets) can be overcome by special tools that, connected directly to the company management, facilitate the task of planning.

The tool that can solve all the aforementioned problems, thus improving efficiency and reducing costs, is represented by APS, advanced planning and scheduling software. APS support the company in an integrated and flexible way in all phases of production planning, from demand forecasting to detailed planning and scheduling of production departments. Interactivity allows the user to interact with the tool, exploiting all company data in a simple way, simulating different scenarios and having evidence of the impacts at all levels. This cycle takes place in real time, allowing you to react to unforeseen events and create solid production plans considering all capacitive and material constraints.

CyberPlan: the most used APS

CyberPlan, Cybertec’s APS, is the best of these production planning software tools, thanks to the most modern technologies used and more than 25 years of experience with Italian and foreign customers.

Companies that replace the numerous Excels with CyberPlan, have in a short time found numerous advantages:

- Increase in service level up to 33%;

- Reduction of warehouses by up to 50%;

- Increased productivity by up to 10%;

- ROI within the year.

These benefits are possible thanks to the strong investments in R&D and innovation, and above all thanks to the close collaboration with hundreds of Italian and foreign companies, from small businesses to large multinationals. This commitment has made it possible to create complete, powerful and simple solutions used effectively all over the world.

Plan and schedule in an advanced way

Learn how to eliminate Excel spreadsheets by enhancing your production planning and scheduling process. Save time, improve your performance! Download the guide