Faber, a leader in the production of hoods and aimed at continuous improvement, has drastically reduced the time required for scheduling, achieved an excellent warehouse turn-over and an enviable level of service thanks to Cybertec’s APS. Interview with Dr. Vittorio Bossio, Supply Chain Manager of Faber S.p.A.

Continuously improve and reach new levels of performance

The Marche-based company is always focused on improving and maximising the efficiency of internal processes. For this reason, with great foresight, almost fifteen years ago it chose to equip its production process with software for advanced planning and scheduling.

Faber had the objective of improving itself by obtaining an improvement in the level of service, increasing the inventory turn-over, eliminating the risk of stock-out, reducing the time required for planning and scheduling and increasing productivity.

Forward thinking in choosing an APS for planning

Faber decided to increase company performance by entrusting production planning and scheduling to APS software directly integrated into the management system. After careful software selection, the choice fell on CyberPlan, thanks to some unique features necessary to achieve all the ambitious objectives:

- calculation speed;

- advanced graphics;

- planning and scheduling in a single solution;

- adaptability and configurability;

- reliability of the system.

In not too distant times, Faber has also changed the structure of its production, moving from 2 production plants distant from each other, to a single one that manages all the production first divided between the two plants.

“Thanks also to the support of CyberPlan, which has allowed us to have full visibility on production plans and a strong improvement in efficiency, today a single plant produces more than was previously done with two plants.” Vittorio Bossio – Supply Chain Manager.

Change ERP without performance reduction

During its path of innovation, the Marche-based company has changed ERP software. This important and challenging step required a huge migration of data. On this occasion, the Marche-based company was able to count on a team of expert Cybertec consultants who remained by its side and allowed a harmonious transition to the new SAP management system. In fact, planning has always remained active throughout the migration without reducing efficiency and performance.

The result: excellent production

Thanks to the CyberPlan solution, Faber has drastically reduced the time required for planning, and continues to reduce it: thanks to CyberPlan implementations, the time required for scheduling today is 1/3 of what it was 5 years ago. This result has also led to an increase in the weekly frequency of scheduling, from 2 times a few years ago to 3 today.

The adoption of a first-level APS solution has also allowed Faber to obtain the simulation capacity and thus be able to verify different scenarios in the scheduling field, which allows it to identify the best plan for the company’s objectives.

The Marche group has thus achieved a considerable level of service, the already excellent 88% has been brought to a value of excellence of 96%.

The inventory turnover is now 8.7, a result of absolute importance that demonstrates the company’s determination to continue improving and to move its standards to ever higher levels.

The stock-out has been reduced, thus allowing Faber to meet the needs of customers in terms of changes in order delivery times.

The communication of the planning department with the sales department has increased and improved thanks to the advanced planning and scheduling software. Today, Faber’s production planning is able to give delivery dates safely and quickly to the sales department, which can then communicate this to customers in a timely manner. Communication has also improved with regard to suppliers: today Faber can rely on a tool that indicates the necessary materials according to the scheduled plan and that allows it to communicate them to suppliers.

Consulting for continuous improvement

“Thanks to Cybertec’s advice, at Faber we continue to increase the functionality and performance of the CyberPlan software, adapting it to new challenges and business conditions, which demonstrates an extraordinary versatility.” Vittorio Bossio – Supply Chain Manager

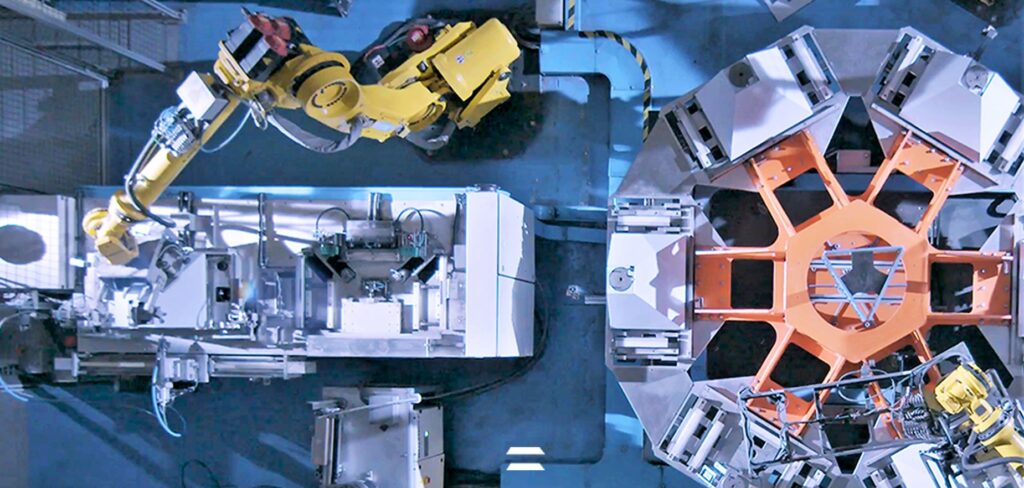

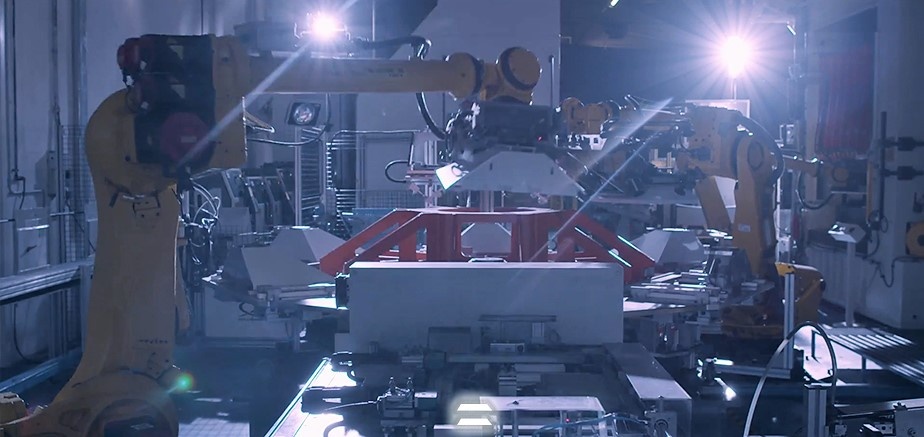

The company: the first in the production of kitchen hoods

Faber was founded in 1955 with the creation of the world’s first kitchen hood, an industry in which it is today a leader. It is an industrial group present with its own offices in 8 countries and 3 continents and which produces a wide variety of suction hoods for its own brand and not. The quantity of MTO (Make To Order) is preponderant and the Marche-based company meets the needs of customers by demonstrating high flexibility and versatility, tackling the consequent high complexity of production in a winning way. In fact, the production of hoods often sees customised products, even if for small batches, with a view to maximum customer satisfaction.

Request a CyberPlan Demo

Request a CyberPlan demo, one of our professionals will answer your questions and support you in understanding how powerful tools like CyberPlan can support you and your company.