A basic rule when travelling on a via ferrata in the mountains is that you should never detach both carabiners at the same time, but only one at a time, so as to always remain attached to the cable with at least one carabiner.

In the course of the life of companies, sooner or later the time comes to change management, the software that most of all represents the heart of the company since it manages a lot of information and data. Changing the management system is not a trivial activity, a bit like having to detach the carabiners at a critical point of the ferrata. Like the hiker who finds himself clinging to a vertical wall with his feet resting on small rock spurs, companies that change their management system find themselves in an equally difficult position, where the processes to be managed are more complex. For manufacturing companies, one of the most important processes is the planning of operations and the change of management can compromise visibility and control over production. In such a situation, changing the management system is a bit like detaching both carabiners: there is a great risk.

For this reason, to avoid losing control over your production, you must manage the production with a special software, to ensure that you always remain insured with at least one carabiner on the wall.

Whatis a production management software

The management software, also called ERP (Enterprise Resource Planning), is a fundamental software for companies of any size, as it helps to optimize and manage the main processes, saving time and reducing the margins of error.

A management software coordinates the data related to the various business processes and simplifies operations. Thanks to this coordination and liaison function, all departments of the company benefit, such as: accounting, invoicing, inventory management, sales and purchasing management, human resources management and production management.

A management software provides a complete overview of business activities in real time, so that executives can make informed decisions based on up-to-date data.

When to change production management?

When the management system in use becomes obsolete compared to actual needs, it is time to change it. An obsolete ERP, in fact, in addition to making the work for the team inefficient and more tiring, can also be an obstacle to the growth of the entire company.

The signals that allow you to realize that the management system in use needs to be replaced can be different: lack of data, need to perform many manual operations to be repeated even daily, poor integration with other software solutions present in the company. Other signs that indicate that the time has come to change your management system are:

- Growing company: coordinating the company’s organisational activities in an integrated way has become difficult, also due to increasingly poor communication between departments.

- The management system does not integrate with other software, making it difficult to exchange data and reducing visibility between departments.

- Difficulty working remotely due to poor software performance.

- Excel used to create formulas and make analyses, with a consequent loss of time combined with the risk of making mistakes.

- Little visibility on costs, especially related to licenses and upgrades and maintenance.

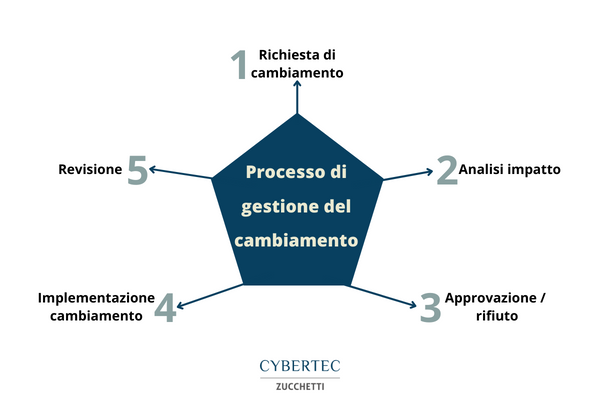

The challenges of management software change

As with any innovation introduced in a company, implementing a new management system also brings with it some risks. Switching from one ERP to another could lead to disrupted workflows and reduced employee productivity.

In general, the main risks concern:

- Unrealistic expectations about the software and what it can do. It is common to expect that new software will help simplify operations by automating them, that it will be easy to implement and use, integrating with the software already present in the company. And in general, it is expected to help achieve business objectives. For this reason, when choosing the software, it is important to know the features and what the software can do. In addition, to maintain realistic expectations, it is necessary to have clear timelines and expected results from the implementation project.

- Choose a standard ready-to-use software. A choice that you fall back on when you want to have ready-made and reliable software immediately available, because there may not be the resources to rely on a development team to make the software tailor-made. The main risk here is that no additional functionality is available to cover specific use cases.

- Inadequate resources for the implementation and testing phases of the new software, which should take place with a dedicated team that knows the company’s specifications, involving all stakeholders and process managers who will be affected by the new software.

- Poor management of the change that involves a failure to prepare users for the transition to the new software, thus limiting its adoption and achievement of objectives. To limit the natural human tendency to resist change, we must work precisely on this human side. So it is necessary to train the staff so that the transition to the new software is easier and the teams are able to identify the necessary process changes. In addition, a communication strategy should be developed with the aim of informing staff about the advantages of the new software, how it can improve the daily work and the quality of the entire organization.

- Poor technological integration and difficulty in data migration in case the new software fails to integrate with other systems. The data on the old management system must be migrated to the new one while maintaining their integrity to avoid losing valuable information. Migration should be seamless and without impacting existing processes. To avoid such risks, the implementation and data migration phases should be closely monitored to ensure that the new software is aligned with the company’s existing IT architecture.

Why choose CyberPlan

As seen, ERP is a software that integrates with many departments of the company, consequently management change involves all business processes and areas and very often becomes an onerous project in terms of resources, time and processes involved.

In manufacturing companies, one of the most important processes that can be put at risk by changing the management system concerns the planning of operations. Poor integration between old and new software and difficulties in data migration can in fact compromise the continuity of operations and cause you to lose control over your production. Added to this is the fact that companies that change their management systems do so at a time of growth and expansion, in a phase where operations management is characterised by greater complexity.

All these critical issues can be avoided by entrusting production planning to an APS (Advanced Planning and Scheduling) software, which allows you to maintain control over production even when the visibility on company data usually guaranteed by the ERP is poor or if there are problems in the transition.

CyberPlan is the suite that for more than 30 years has met all the needs of manufacturing companies in advanced production planning and scheduling. The suite covers all processes from creating forecast plans, to planning feasible production plans, to finite-capacity detail scheduling. The use of CyberPlan therefore allows you to maintain complete and autonomous control over production, overcoming the transition phase between management systems without the risk of compromising operations. And maintaining an optimized production even afterwards.

If your company is in a management transition phase and you want to secure your production, ask for advice to know all the advantages of CyberPlan.