For manufacturing companies, the process of analysing and understanding demand (or Demand Planning) is one of the most important strategic actions for the optimisation of material management and the fulfilment of sales orders, together with the Demand Management process. Being able to make reliable demand forecasts allows in fact a more careful and optimized inventory management, as well as an improvement in the level of customer service and an overall reduction in operating costs. Unfortunately, however, few companies, tending to be the leaders in their respective sectors, have staff belonging to the different company departments dedicated to the forecasting process, which develops a unique and shared demand forecast plan at company level.

The Demand Plan

The Demand Plan, or demand plan, indicates the volume of realistic demand that the company intends to achieve in its forecast horizon, taking into account the supply plan and the sales budget, which establish the resources necessary for production and the set of commercial actions to be taken for sale.

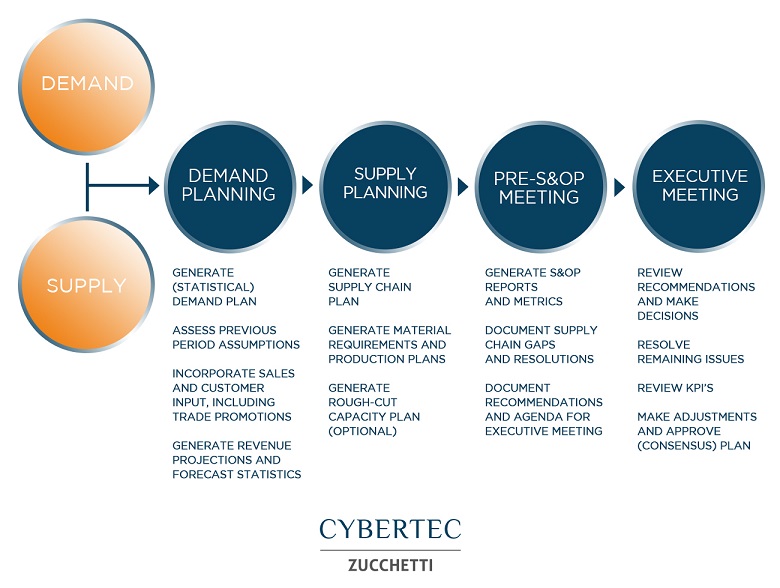

The demand plan is an output of the Sales & Operations Planning process to which both the departments that deal with demand (marketing and sales) and those involved in its implementation (production, logistics and purchasing) contribute. In fact, it is obtained from the cross-analysis of demand, established by sales opportunities on the market, and supply, in particular the possible limitations of production and distribution that depend on logistical-productive structures. The production, distribution and supply plans, established in the short-medium term, then depend on it.

Whatis Demand Planning

The term Demand Planning refers to the set of business processes, management methodologies and quantitative techniques aimed at defining the demand plan of industrial companies. Demand Planning is the set of procedures aimed at analysing, forecasting and managing demand; it requires the use of processes and tools for sales forecasting and correct inventory management. In particular, the Demand Planning discipline aims to define and study the business processes of:

- g generation of sales forecasts;

- generation of the company budget concerning sales (sales budgeting) at appropriate levels of aggregation on products, markets and periods;

- formulation of the final demand plan, with respect for the company’s constraints in terms of production.

The demand plan, generated through Demand Planning processes, methods and mathematical models, quantifies the resource requirements (labor, machinery and materials) necessary to obtain it, supporting planning managers in the formulation of supply plans. The demand plan is therefore the main input for the generation of production, distribution and supply plans.

The Demand Planning process

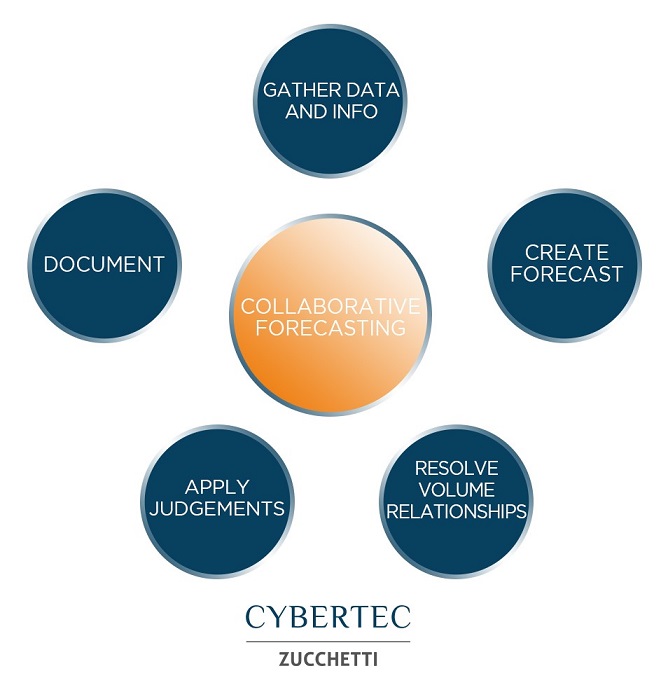

The Demand Planning process is in turn composed of some characteristic macro-processes, including:

- the analysis of historical demand, product and customer characteristics (Demand Analytics & Intelligence);

- the definition of sales forecasts for product-customer segments over time (Sales Forecasting);

- the definition of the demand plan, sales budget and supply plans (Demand & Supply Planning ).

The objective of Demand Planning processes is to manage commercial demand effectively, during the different phases of its life cycle.

Demand Planning and the current situation

Recent research from Aberdeen has unfortunately highlighted a certain backwardness of Italian companies towards the market for IT solutions that are available today to support Demand Planning. As many as 43% of respondents declare that they do not use specific tools or at most use spreadsheets adapted by the operators (and therefore closely linked to the operator and his logic).

Many planners then rely on management software modules (29%), probably ignoring that often the performance of such modules is quite far from what is the “state of the art”, in an attempt to have a single solution that performs all the calculations. Fortunately, 24% of respondents jointly use specialist tools and Business Intelligence solutions, which is probably the most correct approach to forecasting.

The advantages of Demand Planning

Demand Planning is a useful support to the company’s management mechanisms and is essential also and especially in cases where all other variables, such as price or product quality, are useless to differentiate from competitors. So what are the advantages of Demand Planning?

The advantages of Demand Planning are many and start from the possibility of planning for the future by reducing uncertainty. Planning demand means anticipating and managing change, both endogenous and exogenous. Proper demand management allows you to anticipate stock changes and better manage lead times and consequently increase competitiveness, reduce costs, increase the level of service and speed of response to customer needs.

For this reason, among the “best-in-class” companies, awareness of the importance of a correct forecast of demand has now spread; for almost all of these companies, combined with excellent performance in terms of logistics performance and Service Level, the most important strategic action aimed at optimizing stocks and simultaneously improving the level of service, consists in the analysis and understanding of the demand phenomenon.

The role of the Demand Planner

The Demand Planning process is overseen by a professional figure: the Demand Planner, or the one who carries out the activity of forecasting sales and related management of product promotions. However, this forecast, like the consequent promotional activity to be activated, is closely connected to the type of product sold.

Demand Planning software

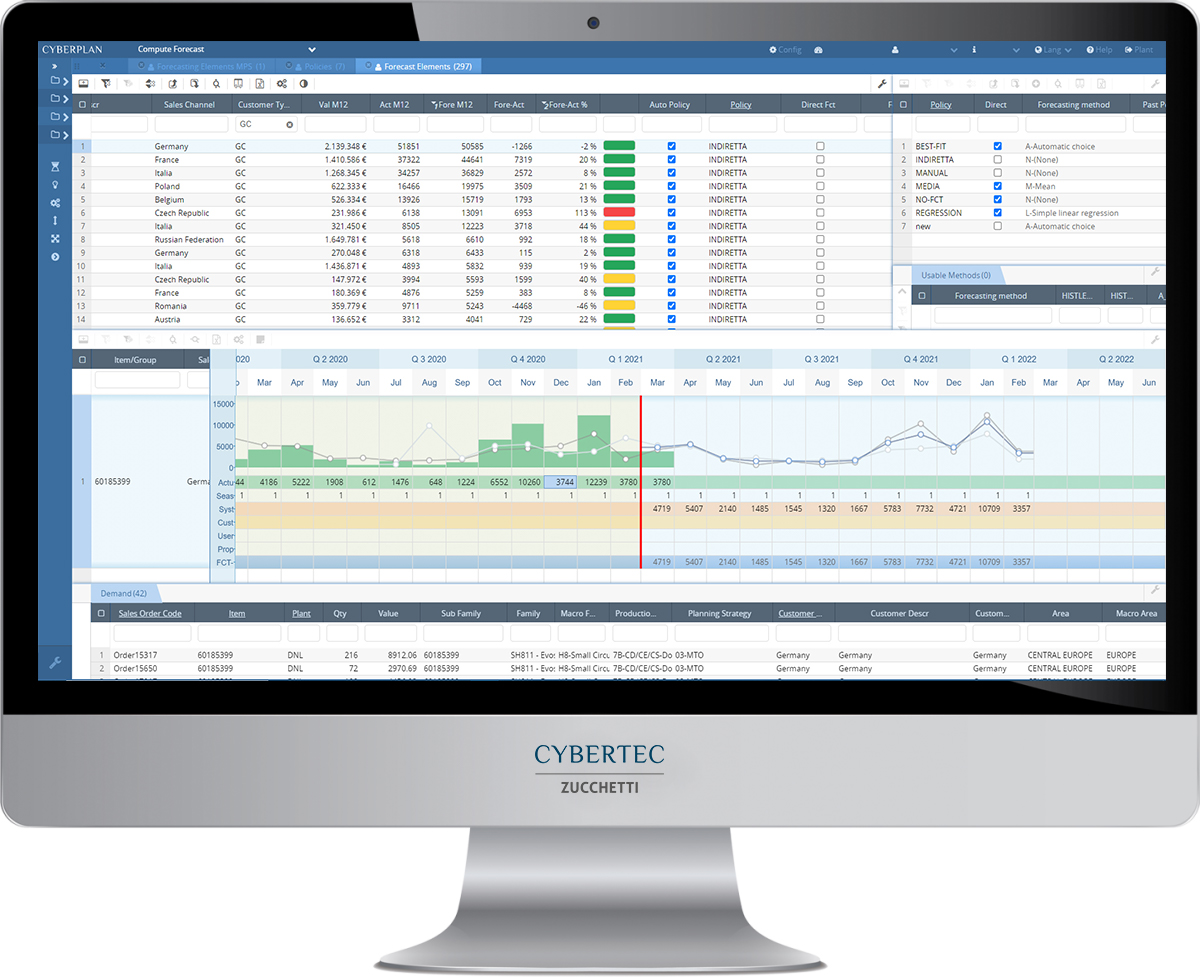

Today, companies have software solutions for demand forecasting and inventory management. These solutions allow manufacturing companies to optimise the supply chain by reducing waste and ensuring correct and timely supply to the market, aspects that are increasingly relevant in the current scenario.

The common operation of a Demand Planning solution involves the analysis of historical sales data, their modeling through regression models, and the return of a forecast curve of market demand as a function of the independent variables considered (regressors) such as the history of inventory consumption, both to the specific variables of the analyzed business such as the weather trend, or currency fluctuations.

In short, with Demand Planning, planners can more consciously manage the purchasing, storage and inventory management processes, suggesting the quantities of products necessary to meet market demand and, at the same time, the quantities of procurement of components and raw materials for production.

Implement Demand Planning in your company

Companies that still today plan demand using forms purchased together with ERP management systems or with simple spreadsheets can improve methods and tools to carry out this fundamental calculation. Today, in fact, Demand Planning software provides irreplaceable support to all those corporate figures who oversee the production process, relieving them of complex tasks and leaving them free to devote themselves to the decision-making process. Find out how to equip yourself with these tools and gain a valuable competitive advantage by asking for more information or a demo from experts at Demand Planning, our purchasing consultants.