Within each Supply Chain it is important to be able to have the correct amount of materials, equipment and labour required to complete any production process or order with optimal efficiency. It is therefore essential to plan the Supply Chain in such a way as to ensure the timely arrival and departure of these goods. All this comes down to what is one of the most important and vital aspects of the supply chain or Supply Chain Planning.

What is Supply Chain Planning

Supply Chain Planning (or SCP) is the component of Supply Chain Management (or SCM) that deals with developing a strategy to balance supply and demand, predict future needs and monitor the implementation of production orders. SCP covers a range of supply chain processes such as production, production planning and predictive modelling. Within a manufacturing company, Supply Chain Planning is therefore represented by the set of operations that concerns the planning of activities both inside and outside the production structure, as well as by the synchronization of operations between the different plants in order to obtain heterogeneous production plans.

The risks of producing without an SCP system

Without an operational plan, the operations department does not have the necessary forecasts for the future, useful to avoid difficulties and to predict all the potential “what-if” that could occur. An adequate plan can in fact signal the occurrence of certain future scenarios and consequently provide adequate responses to critical situations, giving the planner time and way to avoid them. Malfunctions of machinery and plants, adverse weather conditions, delays on the part of suppliers or unforeseen absences of personnel can in fact upset the production plan for the days or weeks to come. Not having an adequate SCP structure means that the company faces these critical situations without having foreseen them, avoided them or at least prepared adequately by facing inevitable damages such as those regarding compliance with delivery dates, optimization of resources or saturation of plants.

The steps of Supply Chain Planning

Supply Chain Planning begins with demand planning by the sales, marketing and manufacturing departments, which produce a sales forecast based on data collected in the past and other information, such as data transmitted by POS terminals. The data is analyzed through spreadsheets or specialized software to identify patterns that can provide clues about future demand.

Demand planning not only predicts demand, but also tries to influence demand in some way, through intentional actions such as price cuts, product replacements, and special promotions.

Once the demand plan has been approved, it results in a production plan that is implemented in the various stages of the supply chain.

Who is involved in Supply Chain Planning

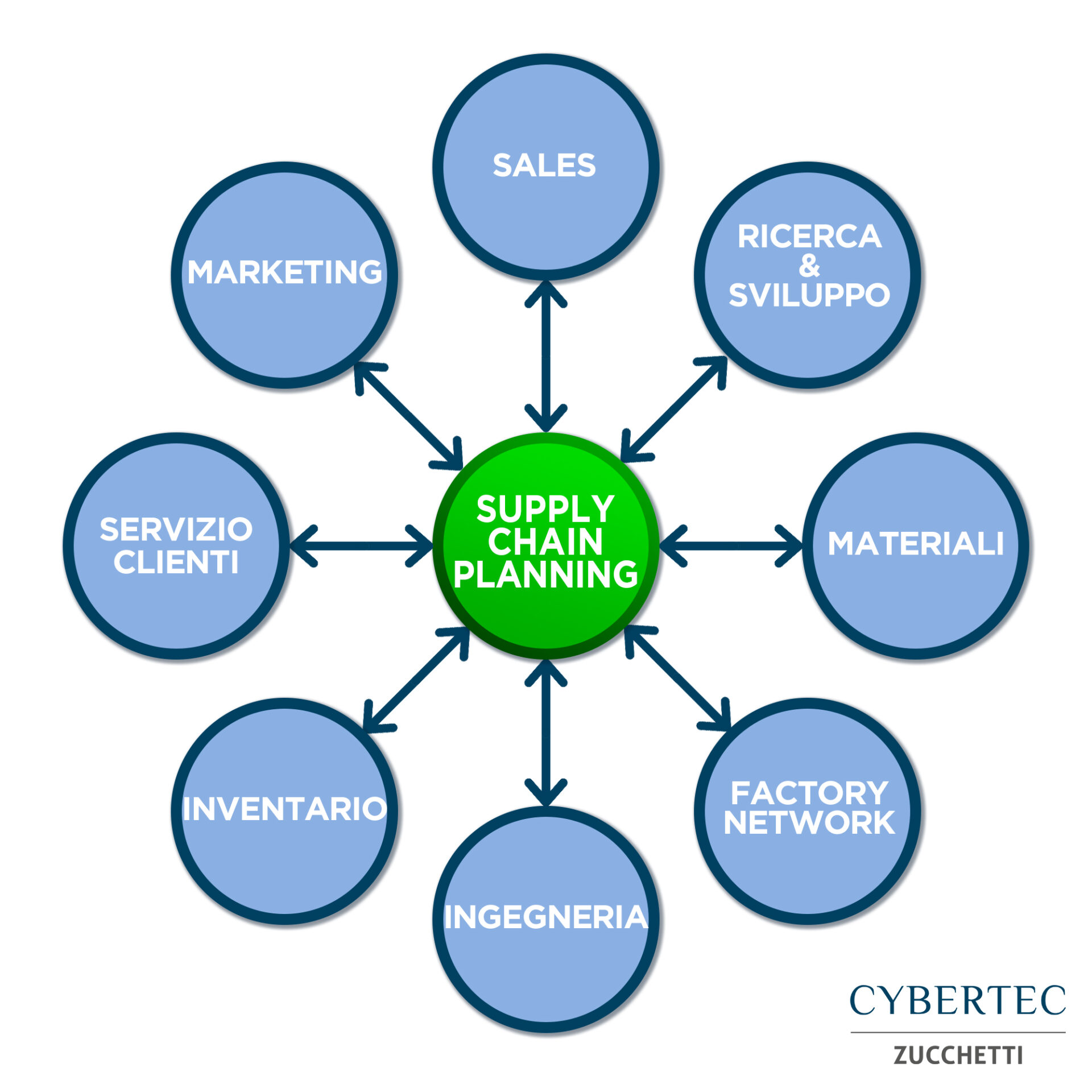

Supply Chain Planning operations have implications that impact multiple corporate figures, however not all are involved in the same way and with the same degree of importance.

The team of the production planning office, with the head of planning and the planners (or Planner), is the most involved, both from the point of view of tasks and time. In fact, the planning office is responsible for drafting the production plan, controlling its progress and its changes in anticipation of certain future events.

Other departments are involved as stakeholders with a dual role, in fact they are people who consult and use the Supply Chain production plan but also provide input data useful for its preparation and modification. These include the purchasing department, with the purchasing manager, the sales and customer care department that deals with providing information to customers about updated delivery dates, and finally the production department that deals with turning this plan into reality.

Fundamentals of Supply Chain Planning

- Data collection: having access to accurate and updated data in real time can be used to improve decision-making processes and manage just-in-time productions. Precise data allows a greater depth of analysis of the supply chain and updated data allows the early resolution of critical situations.

- Inventory management: Updating inventory can enable the use of lean techniques and an overall reduction in costs.

- Identification of inefficiencies: Having an accurate production plan for the Supply Chain allows companies to identify inefficiencies such as waste, calculation errors, shortages in the warehouse and unnecessary costs.

- Consumer forecasts: Having a solution that can track customer behavior and demand can improve profitability and margins.

- Supply Chain Collaboration: Having a model that includes all stakeholders and stages involved in the supply chain helps define processes between customers, suppliers and sellers.

- Product Lifecycle Management or PLM: Having a demand plan supports the transition from product development to product distribution.

- Lean principles: management with the just-in-time method allows a reduction in inventory costs and a much more stable flow.

- Greater visibility: Supply Chains often have imperfections such as waste and calculation errors, an increase in operational visibility can reduce the occurrence of shortages and waste.

- Standardization: Having a system that allows an increase in efficiency will help the Supply Chain both in the short and long term by facilitating an increase in revenue. Having a Supply Chain Planning solution within a planning department promotes collaboration, reduces errors and increases the time to be allocated to high value-added activities while reducing those with low value.

Supply Chain Planning tools

The good news is that there are software tools designed specifically to help companies plan the Supply Chain. Most of these software offer windows regarding the production chain, which visually show critical information such as the inventory of raw materials, orders processed and the progress of the production plan. These tools facilitate the generation of flowcharts and allow them to be shared with other departments or management.

Additional ERP components, such as advanced planning and scheduling systems (or APS), fill the gaps in Excel and ERP regarding the ability to generate feasible, realistic, up-to-date and finite-capacity plans. The adoption of a production planning software allows the company that implements it to extend a given ERP system into a complete Supply Chain planning and scheduling system that makes Supply Chain Planning (SCP) possible. APS systems increase the potential of ERP systems by giving the company predictive analysis, simulations and the construction of hypothetical scenarios.

SCP software can be used to address supply chain constraints or changes proactively and provide real-time up-to-date data. These are applications that are integrated into existing enterprise resource planning (ERP) systems and can perform what-if analysis for hypothetical future scenarios. The best SCP software tools use finite capacity reasoning and include network design, capacity planning, demand planning, production planning, and distribution planning capabilities.

The consequences of implementing an APS solution are tangible and range from improving production operations to improving service level, increasing profitability and reducing inventory costs.

CyberPlan and Supply Chain Planning

CyberPlan is the APS that numerous manufacturing companies have adopted to replace the hundreds of Excel sheets and enhance the ERP by equipping their departments with the production planning capacity and potential that would otherwise be unattainable.

The characteristics that make CyberPlan unique are:

- DataBase in RAM that guarantees a very high speed allowing a continuous human-machine interaction;

- What-If simulation that allows the creation of different scenarios quickly and accurately, helping to choose the best possible plan while preventing risks and profit losses;

- Powerful algorithms that allow optimization of production and better use of available resources, reducing costs and increasing productivity;

- High configurability that allows you to more easily model the production reality avoiding approximations and approaching the peculiarities of individual companies;

- Optimized workspaces that bring the benefits of lean within the software ensuring you have the right information at the right time;

- Intuitive graphics that allow you to immediately identify the critical issues of the plan and their effects, maximising the visibility and control of the entire production;

- Integrability with any external system, allowing a linear information flow with the other tools in use;

- Stability, assistance and specialised advice allow you to enjoy a 360° service.

Thanks to these unique features, the benefits obtained by companies that use CyberPlan concern the increase in competitiveness thanks to the decrease in costs, the increase in productivity and the level of customer service together with a reduction in lead time and time dedicated from planning to activities with low added value.

Equip your company with an SCM solution

Do you need an ERP add-on for planning and planning in your supply chain? You are not alone, but you can equip your company with the best tools and before the others, contact a Supply Chain expert and find out how to get an SCM system.