According to Accenture, 72% of supply chain experts believe that capabilities tied to the Supply Chain Control Tower will be critical to enabling company growth tied to a better customer experience. But what do we mean when we talk about Supply Chain Control Tower?

First of all, not a real tower, but a centralized platform that collects data, metrics, records key business events and thus provides end-to-end visibility throughout the supply chain, allowing you to know more in detail the problems that affect the company, assign the right priorities and solve them in real time.

Whatis the Supply Chain Control Tower

Supply Chain Control Towers are rapidly changing the way the supply chain and its interactions are managed and how they contribute to strategic business outcomes. Today, the Supply Chain Control Tower is a fundamental capability for companies that want to make their network optimized and able to generate more business value.

Going into more detail, the Supply Chain Control Tower is a solution that takes advantage of advanced technologies such as artificial intelligence, the internet of things and machine learning, often in a cloud environment. Within this concept, people, processes, technology, data and events that involve the entire supply chain are united.

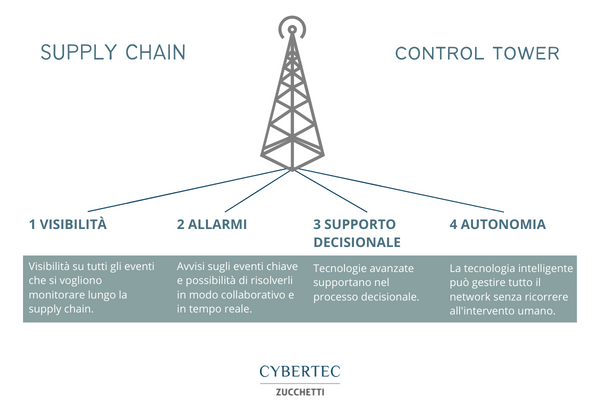

Its purpose is to collect real-time data from across the business ecosystem to increase end-to-end visibility across the supply chain, provide in-depth analysis, and improve short- and medium-term decision-making, aligning it with strategic business objectives. Through a customizable dashboard, it provides real-time visibility and increases the capacity for autonomous and informed execution. Overall, it helps companies make the supply chain more customer-centric, sustainable, responsive and agile.

The basic characteristics concern:

- Transparency and visibility across the supply chain to manage operations from supplier to end customer

- Complete end-to-end integration: horizontal integration across all supply chain processes

- Collaboration

Specifically, the technologies – often based on the cloud – on which the Supply Chain Control Tower is based are:

- Continuous intelligence: to acquire data continuously and in real time;

- Advanced analysis: thanks to predictive and prescriptive analysis, it allows decisions to be made proactively;

- Analysis of the impact of signals from the external ecosystem on the supply chain.

- Scenario analysis: scenario simulation to evaluate different solutions.

- Collaborative response

- Artificial intelligence: greater automation thanks to machine learning.

The benefits of the Supply Chain Control Tower

As can be understood, the main benefits of a Supply Chain Control Tower concern the better visibility that is obtained throughout the supply chain and consequently a series of related advantages, such as improvements in planning, decision-making, proactive management of events and all the performance of the partners and related processes, together with the ability to carry out more sophisticated and detailed analyses.

Companies that choose a Supply Chain Control Tower are able to make better decisions based on data, increase the level of service and thus gain the trust of customers.

Other specific benefits include:

- End-to-end and real-time

visibility into the supply chain: the Supply Chain Control Tower correlates data from different sources and related to different departments, thus gaining insight into external events and trends. The data is then collected and presented in customized dashboards as needed, thus obtaining forward-looking information. - Facilitate the task of making decisions: constant monitoring of data allows you to accurately predict possible supply chain disruptions and to assess the impacts of external events. It therefore becomes easier to define the priorities of the interventions to be implemented.

- Shared information and collaborative environment: the digital collaborative environment with shared information allows you to make decisions quickly and respond to unplanned events while maintaining a high level of performance.

Types of Supply Chain Control Towers

The concept of Supply Chain Control Tower is not new, however initially it referred to an isolated and linear process, able to offer restricted insights to a specific area of operations such as transport, logistics or warehousing. The old Control Towers collected data and returned analytics, but no suggestions on how to deal with the problems. They were on-prime software solutions with limited capabilities, unlike the current ones that are based on Cloud technology.

There are still different types of control towers with specific objectives and characteristics to adapt to different sectors, but unlike in the past they make the most of new technologies. Some examples are:

- For logistics and transport: they give information related to shipping status, delivery dates, tracking and traceability of orders.

- For order fulfillment: They help speed up orders.

- For inventory control: they provide data on inventory management with the aim of preventing stock-outs and shortages.

- For supply assurance: to maintain adequate supply levels to meet needs.

- For end-to-end supply chain: Gives visibility into internal and external systems and processes.

The Supply Chain Control Tower process

The process is based on three actions in a continuous loop that allows you to monitor the situation, evaluate the options available and make the best decisions. The specific actions are:

- See (monitoring phase): allows you to identify the causes of the exceptions that occur, trace the origin of the problems, look at the data and information as a whole overcome the compartmentalization of information in silos, but collecting valuable data from ERP systems and warehouses in an integrated system.

- Decides (decision phase): through the analysis and simulation of scenarios, it creates alarms in response to problems and proposes predictive solutions. The technology and algorithms on which it is based make it possible to assess the impacts of choices and prioritize problems.

- Act (action phase): makes the decision-making process better and faster based on a 360° view of the data, combined with a visibility that can also go into great detail.

The Supply Chain Control Tower software

The Supply Chain Control Tower is a decision support tool based on data analysis that can improve the Sales & Operation Planning process. It is not a standalone application, but a feature integrated into a broader supply chain control tool.

CyberPlan Demand Planning and S&OP is the solution for Manufacturing Forecasting that allows you to make more accurate demand forecasts and balance them with real production capacity. Powerful algorithms and the closed loop approach allows you to continuously monitor the supply chain with real data and make decisions in a fast and informed way.

Learn how to get the most out of your supply chain with CyberPlan Demand Planning and S&OP.