Italy has confirmed itself as a leader in both innovation and drug production in Europe, with a production value that reached 34.5 billion euros in 2021.

The supply chain in the pharmaceutical industry depends largely on the ability of companies to effectively forecast demand for a certain drug, but the forecasting process is not straightforward. In fact, a survey of Senior Pharmaceutical Managers found that most pharmaceutical companies had failed to predict demand for new drugs by up to 25%.

Errors in forecasting occur when the market is volatile and complex, elements that make solutions necessary to plan production according to more flexible and adaptable models.

Whatis production planning in the pharmaceutical industry

In the pharmaceutical field, the concept of production refers to all the activities involved in the preparation of a medicine, so it includes: reception of materials, manufacturing process, packaging and completion of the finished product. Within a pharmaceutical plant, production must take place in accordance with Good Manufacturing Practices (GMP) so that the drugs produced meet the quality requirements necessary to be marketed.

In general, a pharmaceutical plant can present a certain level of complexity that derives from the high volume of products, the different pharmaceutical forms, the type of process and the production mix. In addition, the production planning department must interface with several functions, for example:

- Purchasing department for the supply of raw materials and materials;

- Human resources office for the organisation of employees required for production;

- Maintenance department to evaluate the feasibility of the process from the point of view of the machines;

- Quality assurance to prepare all documentation;

- Technical services for the supply of services necessary for production, such as air, water, steam, nitrogen, electricity, compressed air…

In its daily activities, the production department ensures that the materials received comply with the specifications and stores them in the designated rooms, that the machines are set up correctly and comply with the processing to be carried out, organizes the resources in an appropriate way so that only qualified personnel participate in the execution of the different phases of the process, correctly organizes the processing phases and controls their performance.

The production is therefore divided into several phases and the production line interfaces with many other company departments. Considering these levels of complexity, it is clear how important it is that production planning is as accurate as possible and works to support the needs of the department, both operational and communication for the exchange of information with other offices.

Why Pharmaceutical Manufacturing Planning Matters

Pharmaceutical companies operate in a complex scenario characterized by network fragmentation, high management costs and production constraints due to the obsolescence of raw materials, elements that together become an obstacle to the companies’ ability to react and adapt.

To this intrinsic complexity of pharmaceutical companies, there is another linked to the volatility of the external context. In fact, there are several factors that may influence the growth prospects of the pharmaceutical industry in the coming years, in particular:

- Strict regulations: as mentioned above, products must comply with compliance requirements in order to be launched on the market.

However, regulations can change and be revised from year to year, but this continuous revision of prices and treatment schedules risks undermining the productive sustainability of companies. - Globalization: The pharmaceutical sector is characterized by a very strong global competition that causes the demand for active ingredients to grow. In particular, emerging areas such as the Arabian Peninsula are growing which, thanks to the presence of resources and regulatory flexibility, will be able to attract companies, investments and talent in the coming years.

To this picture are added further elements of complexity linked to the particular historical moment in progress. For example, the Italian industry buys the active ingredients for 75% from Asian countries such as China and India and the sector also has to cope with the increase in the price of gas that has risen three times compared to the 2021 average. These complications have affected the supply of pharmaceuticals, which during 2022 was characterized by the lack of different types of drugs, a deficit made even more serious by the increase in demand from patients.

Precisely because of these factors that contribute to increasing the volatility of the context in which pharmaceutical companies operate, it becomes necessary to use specific solutions to plan production and predict demand reliably, in order to rationalise and optimise supply chain management.

Speaking of demand forecasts, the pharmaceutical supply chain needs two types of forecasts:

- Very long-term forecasts: useful for the launch of new pharmaceutical products that require accurate forecasts for the launch and knowledge of market potential;

- Medium- and short-term forecasts: based on patient demand for drug supply.

The key to successfully overcoming this complex set of dynamics at the production level is flexibility, to be achieved with better business processes and with technical support tools suitable for the operational management of production. To improve production planning and make it more flexible and able to adapt to respond to changes that may arise suddenly, the solution is production planning software.

The advantages of production planning in the pharmaceutical sector

A survey conducted on the pharmaceutical industry showed that most companies tend to overestimate the demand for new drugs by up to 25%, wrong predictions that in some cases can go as high as 50%.

Failure to meet expected demand will result in financial consequences, in both cases of error. If it is underestimated, the lower production results in losses in sales due to the lack of inventory and consequently in large losses in revenue. If, on the other hand, demand is overestimated, perhaps due to excessive market volatility, you end up investing more capital than you should.

Frequent errors in demand forecasting occur because there is a lack of accurate baseline data from which to make forecasts. At the same time, making accurate demand forecasts can be challenging for businesses, especially if you don’t use supporting technology tools.

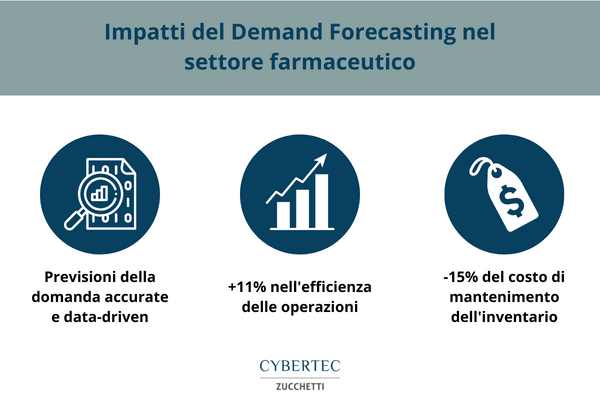

With forecasting tools, companies can manage long time horizons, produce forecasts with low margins of error, and create optimized production plans based on forecast plans. Planning production and making it flexible is the solution to overcome inaccuracies and recurring errors.

Software for pharmaceutical production planning

The tool that responds to forecasting and planning needs is APS, Advanced Planning & Scheduling software.

The pharmaceutical company Delpharm, for example, has boosted planning and scheduling activities with the CyberPlan APS. The plant experienced the typical problems of pharmaceutical companies: a production of about 350 finished product codes, variable batch sizes, the need for flexibility to reschedule production sequences even on a daily basis. The company chose CyberPlan for the ability to obtain feasible plans thanks to the presence of MRP algorithms and the scheduler in the same solution and for the ability to simulate.

Delpharm has therefore overcome the limits of an “old-fashioned” planning based on Excel sheets and unable to communicate with the management system. The company managed to obtain optimised production sequences and overcame problems related to the obsolescence of materials, which resulted both from the expiry of materials and from regulatory reasons, taking advantage of preventive alerts.

Another pharmaceutical company to benefit from CyberPlan is Unifarco, where the increase in the product portfolio and commercial expansion had made it necessary to improve production planning. By planning production with CyberPlan, the company was able to reduce stock outs, obtain unbiased and objective analyses, and better coordinate production and packaging departments.

CyberPlan is therefore the ideal ally to solve the production problems of pharmaceutical companies, because it allows you to plan production starting from the preparation of forecast plans, through the creation of feasible production plans to the scheduling of individual activities.

If you want to learn more about how you can improve production planning with CyberPlan, download the brochure.