In every sector, the market is becoming increasingly dynamic and competitive. For this reason, companies are constantly looking for innovative solutions to manage the entire production system in a rational and organised way, in order to optimise processes and maximise their efficiency. And this is where the production plan plays a fundamental role. How to do it, with what tools and according to what example?

Production plan: why it is increasingly relevant in the company

The production plan is the strategic document that defines how and how much to produce in a given period of time, in order to meet market demand and achieve operational efficiency. It is an indispensable piece in any production process, since it identifies the roadmap to follow in order to allocate resources, plan production and achieve the established objectives, in a clear and specific way.

Today’s challenges in implementing the production plan

The current landscape poses ever-increasing challenges in production planning and for production to be effective, it is important to be ready and able to manage quickly:

- Changes in demand. One of the greatest complexities of the planning process is certainly the unforeseen evolutions in demand. In these circumstances, flexibility and adaptation are key.

- Cost for implementation. Creating and implementing a production plan is time-consuming and can involve significant costs. However, these costs are often amortised by increasing production capacity and reducing waste.

- Need for staff training. Implementing a production plan can be complex for company staff. It is therefore crucial that this is properly trained to follow the new procedures.

How to make an effective production plan: 10 recommended steps

We have seen how creating an effective production plan can represent a significant challenge for companies and the professionals who deal with them. Adopting a methodical approach that includes detailed scheduling and following the following steps can make the process easier:

Demand analysis

It is the first fundamental step of the planning process, as it involves the collection of data on demand forecasts for the products or services offered by the company, through the study of market trends and competition.

Review of existing assets

Assessment of current business resources, to determine if they are sufficient to meet expected demand or if new investments need to be made.

Definition of objectives

Based on available resources and sales forecasts, medium- to long-term production targets are established, which must be clear, realistic and measurable.

Development of the preliminary plan

This is followed by the creation of a preliminary draft of the production plan, which will eventually be modified or supplemented based on the information collected subsequently.

Production sequence planning

It is the phase that determines the order of the activities related to the production process, in order to meet demand.

Labour Planning

It establishes how many employees are needed and what skills they must possess to achieve operational efficiency, based on production needs.

Raw material planning

The necessary raw materials are decided and orders are planned in order to avoid production interruptions.

Monitoring and control

Once the production plan is implemented, the progress of the activities is constantly monitored by tracking performance, identifying any deviations and making the necessary changes.

Review and adjustment

Periodically, the plan must be reviewed and, if necessary, updated on the basis of actual production data and changes in demand.

Post-production evaluation

After completing the production, it is time to evaluate the results obtained, in order to identify any areas for improvement for the future.

Simplify the production plan with the latest generation software solutions

To simplify the creation and implementation of a production plan, there are several software solutions, some more standard and others of the latest generation.

Among the options available in the company but which have some limitations:

- MES (Manufacturing Execution System) software.

In fact, although they offer constant monitoring of production activities, they often lack advanced planning. - PPS (Production Planning System) systems.

Designed specifically to support companies in the planning and monitoring of production, these software focus exclusively on the management of short-term production activities.

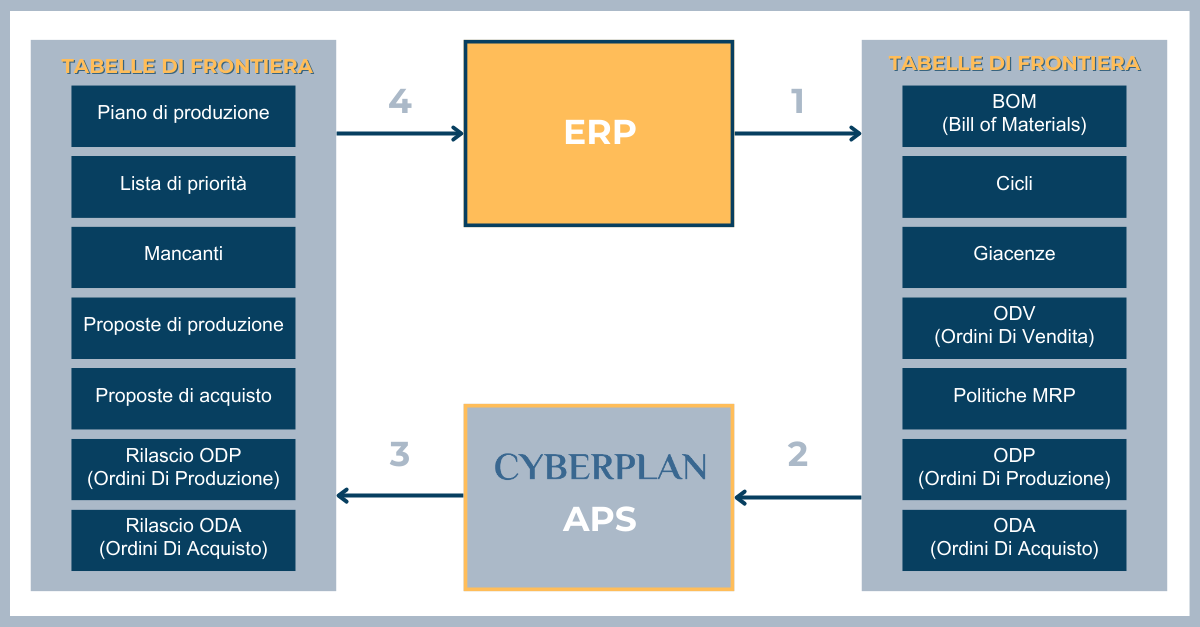

To overcome the above, there are state-of-the-art solutions such as APS (Advanced Planning & Scheduling) software . These systems use complex algorithms to analyze in detail the availability of resources, stocks of raw materials, demand forecasts and other factors, in order to develop a complete and efficient production plan. One of the most advanced APS software is CyberPlan. Thanks to this tool, it is possible to map the entire production process, optimising the flow of activities and maximising production capacity.

Production plan: an example

In order to bring tangible results, the planning activity must be able to rigorously align the needs of the market and the production capacities of the company system.

Molteni Farmaceutici, a leading Italian company in the pharmaceutical field, has implemented the CyberPlan APS software to innovate production planning.

The software, based on a finite capacity planning model, allows you to optimize production resources and reduce waste.

With CyberPlan APS, Molteni Farmaceutici has obtained the following advantages:

- Accuracy of planning, with evidence of all production constraints. This has made it possible to avoid errors and excessive consumption of resources.

- Improved visibility throughout the supply chain, thanks to the comprehensive overview of production activities, which allowed the identification of potential problems in advance and the consequent development of supporting procedures.

- Increased production efficiency and customer satisfaction, through the reduction of time-to-market and delivery times.

- Simplification of internal and external processes .

- Greater flexibility. The software has allowed the company to adapt to changing market contexts, being able to automate planning activities according to different scenarios.

Another virtuous example is that of the company Nutkao, which operates in the food sector producing spreads based on hazelnuts.

The implementation of CyberPlan APS has brought several benefits to the company, including:

- The optimization of demand and supply forecasting, with a relative decrease in the waste of raw materials and finished products

- Better use of production resources

- Significant reduction in downtime and waiting times

- Agility in creating new production lines, without having to change the planning and scheduling system

- Information sharing and dialogue between “lean” functions, as everything is managed in a single solution and through automated processes.

Successfully used by numerous companies belonging to different sectors, as told in many other case studies dedicated to production planning, CyberPlan APS is the optimal solution for those who want to increase their competitiveness, improving efficiency, increasing the level of service and reducing costs and consumption.

Download the brochure to learn more and see how an advanced planning and scheduling tool can support you and your business.