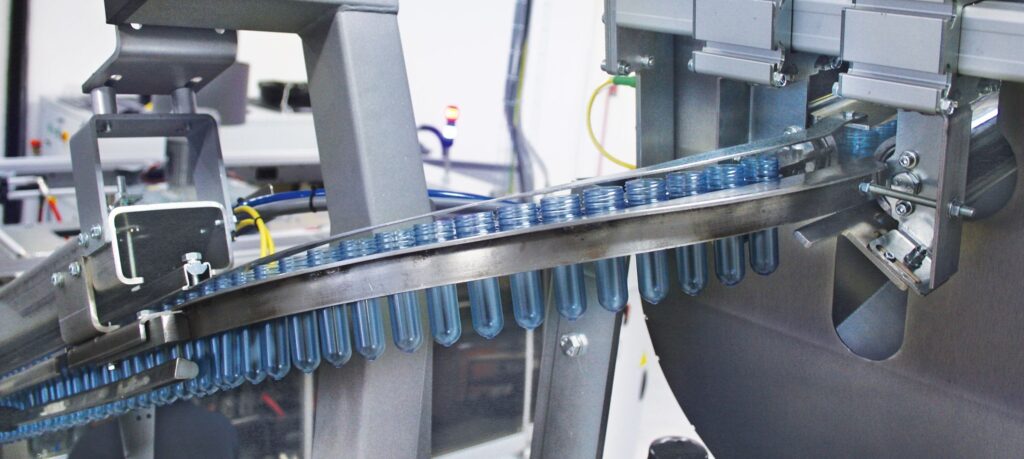

Leader in the production of bottling plants and machines

SMI S.p.a. is today one of the largest manufacturers of bottling plants and packaging machines worldwide. The production was characterized by 4 ranges and 100 product models (for about 300 orders sold on order configuration), a high variability of raw materials, a multiplicity of suppliers involved and the finished capacity of the production

departments.

Improve the production process to support strong growth

The strong growth of the company and the business has pushed Smi Group to make a choice that improves processes to recover efficiency throughout the production phase: moving towards the logic of “kaizen” (continuous improvement) has allowed a considerable enhancement of company performance.

The constant increase in the complexity of production has raised awareness that the planning systems in use would not be as effective as in the past in managing new production volumes.

SMI Group therefore began the search for the best IT tool for production planning and scheduling that would guarantee it:

- Maintain a high level of service by maximising production efficiency;

- Avoid missing production orders;

- Send the purchase request within the lead time provided by the supplier;

- Have a prompt reminder report;

- Quickly reschedule purchases;

- Level the production loads according to the raw materials available;

- Simulate different scenarios;

- Prepare the annual budget and related semi-annual reviews.

Software for advanced and finite-capacity production planning and scheduling

CyberPlan was chosen, Cybertec’s Advanced Planning Scheduling (APS) which, thanks to its ability to reason according to the assigned constraints, such as the delivery date or the available production capacity, allows to accurately determine the delivery dates of sales orders and consequently all production and purchase orders. This in turn makes it possible to level the loads of the production departments and suppliers to ensure the delivery of the finished product within the time agreed with the customers with good precision.

The mutual collaboration between the Cybertec team and Smi Group together with a very detailed comparison and analysis of the production processes made it possible to comply with the planned implementation times. The Cybertec staff has proven to be prepared and expert on the different topics related to the specifications of our company, a fundamental aspect to adapt a multipurpose solution such as CyberPlan to a production reality with specific and complex needs such as Smi Group.

Optimised production plans

The main result, considering the company’s critical issues, was to define the weekly work plan to be provided to the managers of the various production departments for the organisation of the production process. This plan is balanced with respect to the load of the production departments according to the availability of materials and the available workforce. CyberPlan responds to the needs listed above through finite capacity scheduling and reporting the missing with medium and short term plans.

SMI Group is now able to:

- align production with demand and purchases;

- accurately determine delivery dates;

- balancing the loads of the production departments;

- achieve feasible plans aligned with business objectives in just a few minutes.

“Thanks to CyberPlan today we are able to accurately determine the delivery dates of sales orders and consequently all production and purchase orders.”

Rodolfo Rossini – Industrial Coordination – SMI Group

{{cta(’69ae472b-b1a4-4be1-82b2-6dd98ccd7f1e’)}}