In everyday life we are dealing with a multitude of products and services. If you want to understand what Operations Management is and what it deals with, it is from them that you have to start, because it is precisely here that its role begins.

In fact, Operations Management looks closely at the production of these goods and can see inside that black box that is the production process. It therefore manages the entire process that transforms inputs (in the form of raw materials, labor and machines) into outputs (material goods and services, in fact).

A central aspect of his role is to try to improve the transformation process as much as possible, applying concepts and methodologies such as Total Quality Management, Kanban and Total Productive Maintenance.

It is, to all intents and purposes, a complex and multifaceted management role, which has great strategic importance within the company, especially considering the increasing importance of planning.

Whatis Operations Management?

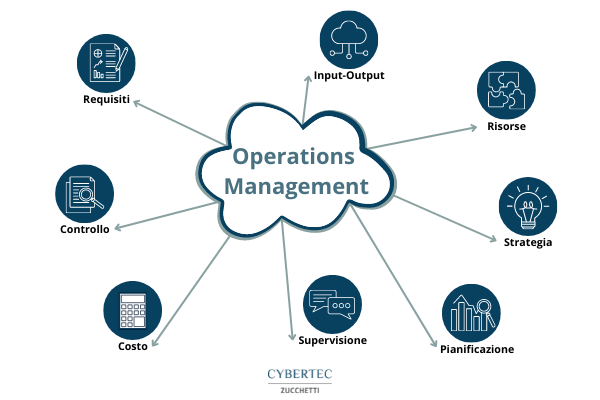

Operations Management (OM) is a type of business management that deals with the planning, design and control of all business operations that are used to create products or services. The aim of OM is to manage all these activities by balancing costs and revenues, thus ensuring the highest possible level of efficiency and maximising profit.

Operations Management is a complex and multifaceted role, because it has to deal with managing the entire process of transforming the various inputs into outputs, while making different types of decisions. These can cover aspects such as operational strategy, product and process design, quality management, production planning, capacity and inventory control. It must therefore be clear about many business aspects and have a strong analytical capacity to assess the current situation and find the best solution to improve the effectiveness and efficiency of operations.

What is Operations Management for?

Simplifying extremely, it could be said that the task of Operations Management is to ensure effectiveness and efficiency within the company. Specifically, effectiveness in terms of satisfying customer needs and efficiency in terms of using as few resources as possible.

The OM therefore has a very strategic function in that it directs and controls systematically and on a daily basis all the processes that transform input resources into finished products and services for customers. Therefore, it must also make a series of operational decisions related to the size of the production facilities, the management of inventory levels, quality control and the implementation of the IT structure.

Who is involved in Operations Management?

The corporate figure who deals with Operations Management should be a multifaceted professional with established skills in different areas. First of all, it should have a solid knowledge of the logistical aspects to manage processes and operations smoothly throughout the supply chain.

In order to make timely decisions on the purchase of raw materials, use of labor, inventory levels, choice of suppliers and delivery of goods on time, this professional must have vision and awareness of local and global trends in the sector and be aware of any financial regulations and political uncertainties.

Its qualities should also include versatility and innovation. Having to coordinate and develop new processes should also be expert in recent trends in operations management, such as the concepts of Agile and Lean technology.

Supply Chain Management and Operations Management

Considering what Operations Management deals with on a daily basis, it may seem that the boundary between this role and that related to Supply Chain Management is poorly defined and that the two areas sometimes overlap. In fact, the two roles have different aspects in common, both contribute to adding value to the business, creating more efficient processes and, ultimately, leading to greater entry for the company. In reality, however, despite these similarities, these are two very distinct roles and processes.

Supply Chain management is in fact more focused on what happens outside the company, dealing, for example, with negotiating contracts and evaluating suppliers. While Operations Management deals more with what happens within the company, planning and supervising daily operations and processes.

Several yes, but also deeply linked. In fact, creating a product and bringing it into the hands of the consumer is a complex process that involves several processes, both internal and external, as well as other companies. And it is precisely on this duality that these two types of business management are structured. Supply Chain management allows the control of the process for the realization of products or services, Operations Management supervises all the operations essential to their creation. The one could not exist without the other.

The tools for Operations Management

Today, those involved in Operations Management can rely on a series of tools and technologies that help in the difficult tasks of planning, monitoring and coordinating production or service operations. These allow, for example, to digitize the daily workflows of the employees involved or identify and mitigate any problems with operational processes.

Using the right tools is increasingly crucial, especially considering the central role that production planning has played over time within production. Planning relying only on Excel, a practice still widespread in many companies, is a risk that can no longer be taken.

In addition to the tools for production planning, not to be underestimated are those for planning services, which allow you to manage an increasing volume of projects ensuring reliability on time and a correct use of available resources.