Every manufacturing company is interested in measuring their level of productivity, but what tools can be used? Let’s discover OEE (Overall Equipment Effectiveness), an effective and particularly useful measure for the production department of every industry.

Whatis OEE

Overall Equipment Effectiveness (OEE) is the gold standard in measuring manufacturing productivity; it is a percentage index that measures the total effectiveness of a production operation and summarizes in itself three very important concepts from the point of view of manufacturing production: the availability, efficiency and quality rate of a plant.

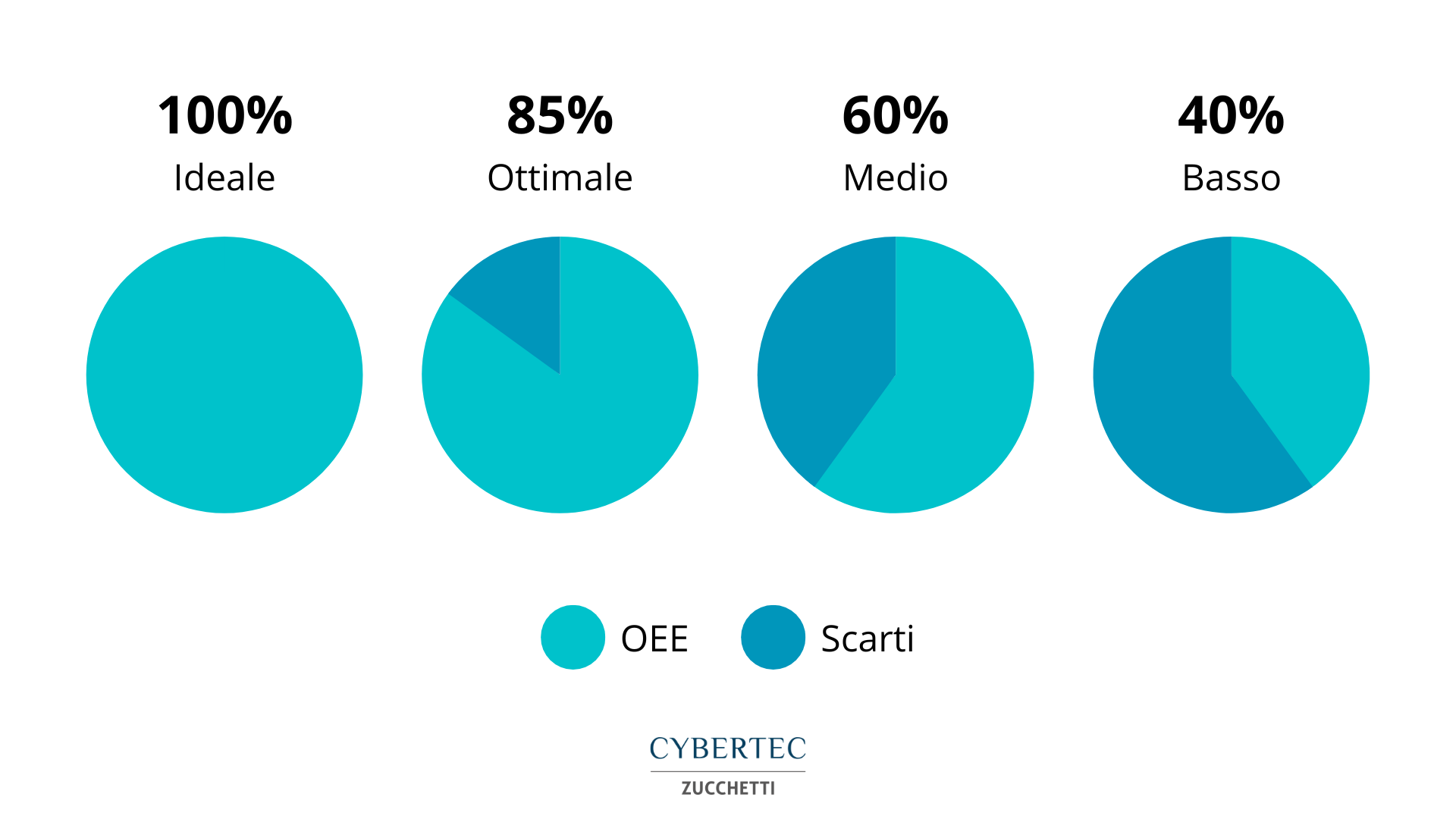

The OEE is a measure of the effectiveness of the use of a production operation (structures, time and materials) compared to its full potential, during the periods in which it is expected to be carried out. Identifies the percentage of production time that is truly productive. An OEE of 100% means that only good products are made (100% quality), at maximum speed (100% performance) and without interruptions (100% availability).

Keeping OEE monitored is a manufacturing best practice. By measuring the OEE and the underlying waste, important information can be obtained on how to improve the production process. OEE is an effective metric for identifying losses, comparing progress, and improving the productivity of production equipment (i.e. eliminating waste).

The 4 pillars of OEE

Having a predefined diagram of the impact of machine availability, performance and quality, OEE allows you to keep track of hidden problems and their causes. The OEE allows you to have a useful platform to improve the production process. Using the basic concepts of OEE such as “The Six Big Losses” it is possible to understand this platform and implement efficiencies.

The 4 components of the framework are:

- OEE

- Availability

- Performance

- Quality

The OEE is a very simple metric that allows you to immediately see the current state of the production process but it is also a complex tool that allows you to understand the effect of the various problems of the production process and how they affect the entire process.

The simple formula of the OEE is “availability” multiplied by “performance” and by “quality”, which in the form of an equation becomes:

OEE = Availability x Performance x Quality

Availability

Availability refers to the machinery available for scheduled production. At the simplest level, when a process is active it creates value for the end user. When it is interrupted, it generates a cost without an associated value. Whether due to mechanical failures, missing raw materials or absence of operators, the machinery can be in two states: productive or non-productive. By comparing the scheduled run time with the actual one, the OEE availability component allows you to determine a loss of production due to downtime.

Performance

Performance is established based on the amount of waste that is generated using the machine at a lower speed than the optimal one. By comparing the current working cycle times with the ideal ones, the OEE allows to determine how much production was lost by working cycles that differed from the optimal one.

Quality

Quality focuses on identifying the time that has been wasted to make a product that does not meet quality standards. By comparing the quantity of pieces to be discarded, the percentage of time that actually adds value by producing a suitable product is highlighted.

How to calculate OEE

The OEE formula allows this value to be obtained as a product of the three fundamental components of production performance, namely availability, performance and quality. Availability is the percentage measure of time worked versus time available. For this value, the ratio between the available working time of the plant (for example the shift or the day or the week) and the real time in which the plant has produced value by making parts or semi-finished products is used. Performance indicates the percentage of parts actually machined compared to those theoretically machinable. In the planning, the workpieces that can be machined at optimum speed are calculated, any reductions in these performances indicate a decrease in production. Finally, the quality shows the percentage ratio between the compliant parts with respect to the total parts produced. In this way, there are production declines related to scraps or reworking that affect the overall inefficiency.

An example of OEE

Let’s now look at a practical example of OEE calculation. Let’s take these data:

| DATA | VALUE |

| Shift Duration | 8h (480′) |

| Pause | 2 x 15′ + 1 x 30′ = 60′ tot |

| Downtime | 47′ |

| Ideal cycle time | 1.00″ |

| Products made | 20,000 |

| Discarded products | 510 |

Planned production time

The calculation of the OEE begins with that of the planned production time. Therefore, times when production is not planned, typically breaks, are excluded first.

| Formula: Shift – breaks | |

| E.g. 480′ – 60′ = 420′ |

Run time

The next step involves calculating the time when production has actually been active (not interrupted or stopped). It should be remembered that the stop time should include both unplanned outages (e.g. faults) and planned outages (e.g. replacements)

| Formula: Planned production time – Stop time | |

| Ex. 420′ – 47′ = 373′ |

Compliant products

If you do not track compliant products consistently, then you need to calculate them.

| Formula: Products made – Products discarded | |

| E.g. 20,000 – 510 = 19,490 |

Availability

It is the first of the three OEE factors to be calculated. It serves to highlight when the production process is stopped (both scheduled and unscheduled).

| Formula: Run time /Planned production time | |

| E.g. 373′ / 420′ = 0.8881 (88.81%) |

Performance

The second factor of OEE is used to indicate when the production process is carried out at a lower rate than its theoretical maximum speed.

| Formula: Ideal cycle time x manufactured products/ Run time | |

| E.g. 1.00″ x 20,000 / (373′ x 60″) = 00.8937 (89.37%) |

Performance can also be calculated thanks to the ideal run time, which in our case is 60 products per minute.

| Formula: (Products made / Run time) /Ideal run time | |

| E.g. (20,000 /373′) / 60 products per min = 00.8937 (89.37%)’ |

Quality

The third factor of the OEE to be calculated indicates the number of products that do not meet the quality requirements and are therefore not ideal.

| Formula: compliant products/manufactured products | |

| E.g. 19,490 / 20,000 = 00.9745 (97.45%) |

OEE

Finally, the OEE can be calculated by multiplying the three factors of the OEE.

| Formula: Availability x Performance / Quality | |

| E.g. 88.81 x 89.37 x 97.45 = 0.7673 (76.73%) |

The OEE can also be calculated using a simpler calculation, namely:

| Formula: (compliant products x ideal cycle time) /planned production time | |

| E.g. (19,490 x 1.00″) / 420′ = 0.7673 (76.73%) |

The result is the same in both cases.

I OEE software

OEE (Overall Equipment Effectiveness) software allows you to monitor and measure the productivity of production machinery. These tools that allow you to evaluate business efficiency are often APS and are useful complements to production management software.