Marcolin has reduced lead time and increased business control thanks to CyberPlan, a tool with which he plans high-end eyewear production processes. Tell us about the success story of Daniele De Bastiani, Production Planning Manager at Marcolin.

Marcolin: world-class craftsmanship

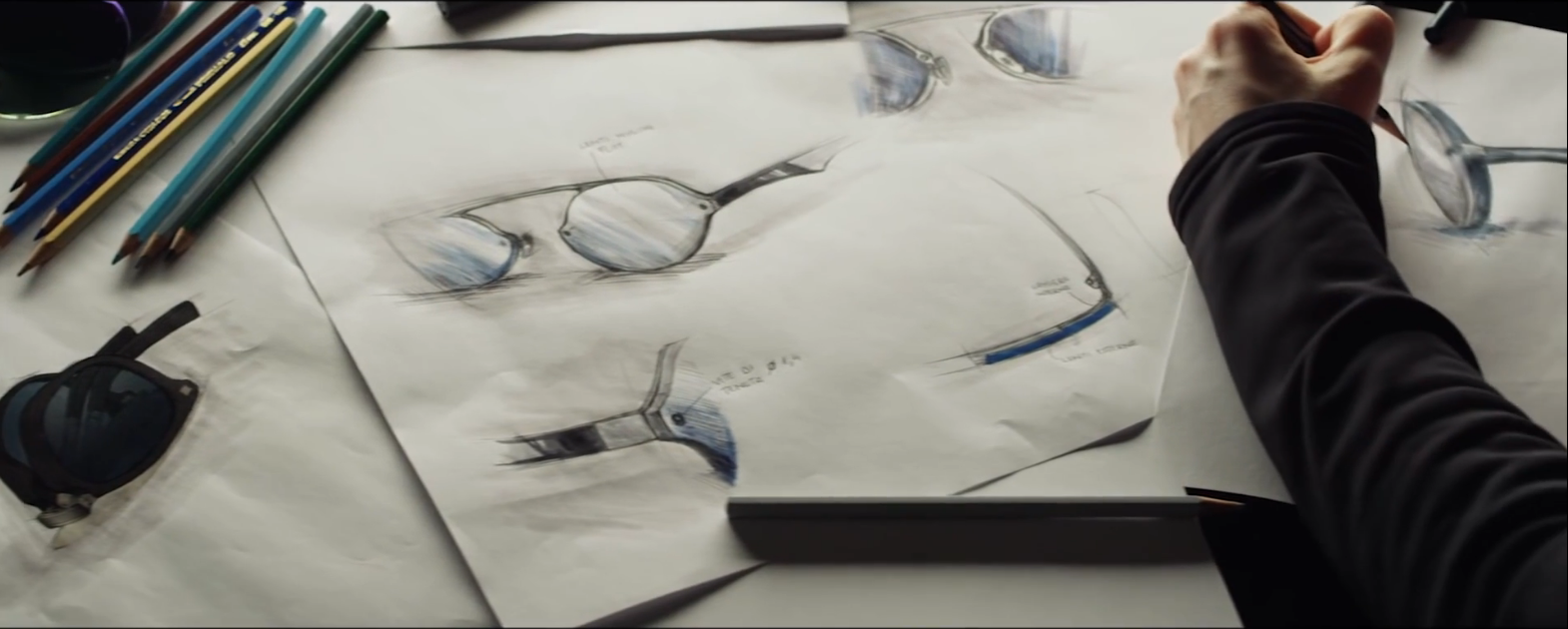

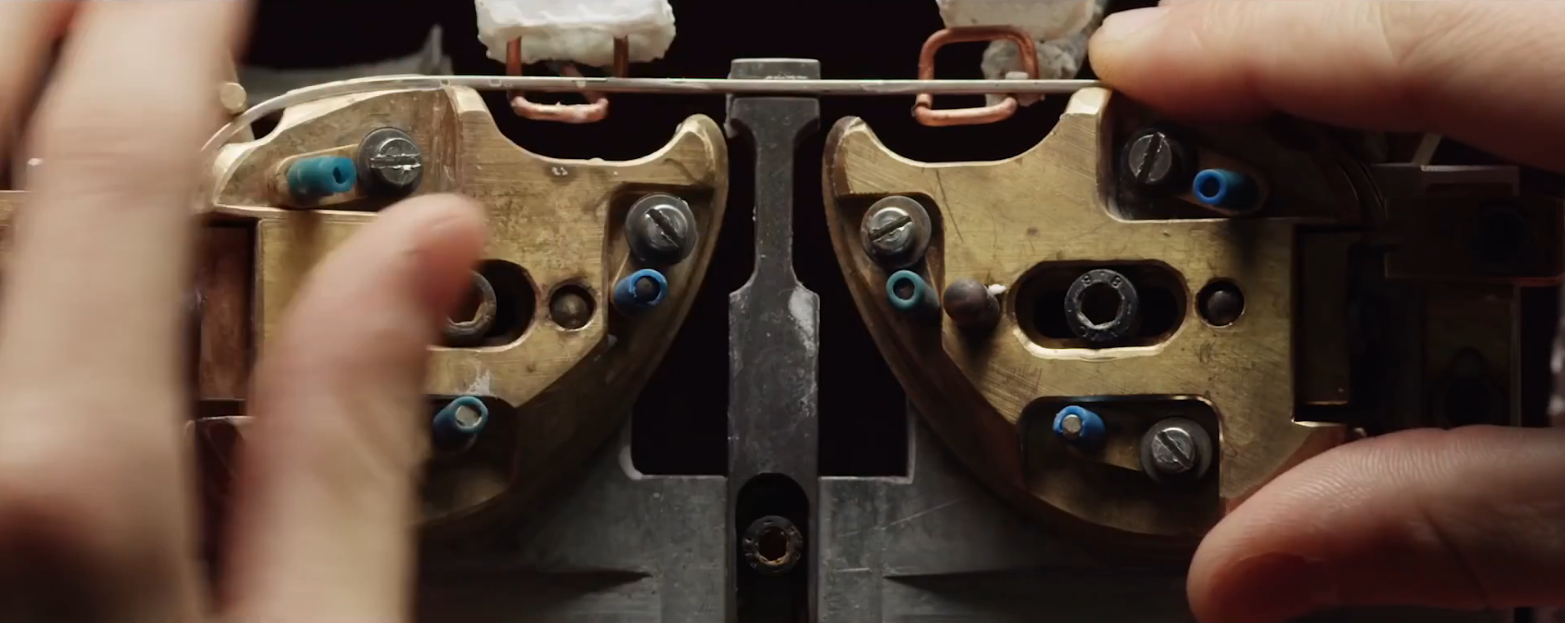

Marcolin is a unique eyewear manufacturing company, founded in 1961. A company where craftsmanship and manual work have remained predominant, where behind every product there is still a large part of craftsmanship. In fact, Marcolin stands out among the operators in the sector for the high quality of its products, its stylistic skills and manufacturing capabilities, its attention to detail and its prestigious distribution. Thishigh rate of craftsmanship translates into a large number of artisans, whose work must be best organized to keep the various departments balanced and at the same time ensure the best planning and working conditions for the approximately 1,900 employees.

Eyewear and features of the fashion world

Marcolin’s production belongs to the world of fashion, which has typical characteristics of the sector, such as variability of the production mix, high SKUs (Stock Keeping Units) and a relatively short life cycle (compared to the lead time necessary for its production). The launch of the model is therefore a critical phase during which there is already a lot of play.

Numerous challenges and objectives for an ambitious project

Marcolin, in advance of the competition, and with considerable foresight, decided to implement the programming of its production. Marcolin’s objectives, numerous and different, had impacts on departments and aspects that were also very different from each other.

Characteristic of the project was the management of a large number of employees as well as the need to keep the various departments balanced. Another aspect to take into account was the high variability of the production mix. Added to these was the creation of a good control and business vision system capable of providing visibility beyond the year, in order to be able to make prudent decisions in advance, allowing the budget to be allocated for the following year.

The solution: production scheduling with an APS

To overcome these challenges, Marcolin decided to use the CyberPlan APS (Advanced Production Planning and Scheduling) solution, chosen in 2001 after careful software selection.

Marcolin chose CyberPlan over 15 years ago, immediately obtaining warehouse visibility, reduced set-up times and perfect management of the production mix. Thanks to CyberPlan, Marcolin then increased visibility into the trend of stock levels by comparing the projected evolution with respect to the target so as to be able to manage production capacities and purchases to be issued. This has allowed the control of raw material levels to be maintained, despite the considerable and continuous growth of the group.

Cybertec’s APS solution is also used to plan the production of suppliers, with whom it is thus programmed in full harmony and sharing, implementing relationships in the supply chain and eliminating misunderstandings and potential problems arising from communication difficulties. The scheduling of suppliers is thus managed and agreed, as if it were an internal department of the company.

Strong growth and change in company management

Since she started using CyberPlan over 15 years ago, Marcolin has grown tremendously. It is therefore not surprising that during this period the management software changed, moving from a niche product to one of the best known ERP software: SAP.

“The transition went smoothly, and CyberPlan helped us keep production going.”

As De Bastiani tells us, the Venetian company in fact had no problems during the management transition, also thanks to the fact that the CyberPlan solution continued to work during the transition phase. In a delicate step such as those of the management system, CyberPlan allowed Marcolin to keep production active without losing working days, an aspect that is not secondary for such an important company.

Production planning has thus undergone changes, made necessary as a result of these evolutions, which have allowed the company to increase communication and sharing of plans between different countries.

The Venetian company, also as a result of growth, has changed the organization of production and planning. CyberPlan has always easily adapted around the needs and during all Marcolin changes, supporting the strong growth. So even when the 3500 sqm production plant in Fortogna was opened in 2015, which meant the doubling of its internal Made in Italy production, the manufacture of glasses started from the day of opening, in a natural and immediate way. In all this, the logic and coding of the CyberPlan solution remained unchanged.

A planning solution for different time horizons

Marcolin’s production schedule goes well beyond the year. At the same time, the planning horizon of the Venetian company also reaches the daily detailed scheduling. To do this, it uses the CyberPlan tool, thanks to which it carries out:

- Forecasting and budgeting for the following year based on expected needs at the cluster level. In this phase, decisions are made to make or buy and purchase machinery and production resources when necessary, given the company’s growth;

- Medium-term planning is useful for the definition of trends and for the possible revision of the initial forecasts, made during the forecasting phase;

- Finally, the detailed scheduling, which refers to the short period and therefore to the weekly or daily planning by department that is carried out taking into account the constraints and that allows the possible reminder of missing materials.

The result: software and consultancy to support planning

Developments and adjustments over the years, as well as changes following requests from company management, have been carried out by Marcolin production planning together with Cybertec consultants. This teamwork has meant that over the years numerous specific solutions have been created for Marcolin and that the tool has evolved alongside the company.

“The collaboration has always been excellent and has led to excellent results“

In particular, the main results were:

- Perfect management of the mix and the numerous SKUs;

- Warehouses under control;

- Reduction of set-up times;

- Reduction of lead time;

- Management of changes to the production plan;

- Increased production.

Request a CyberPlan Demo

Host a CyberPlan Demo to see for yourself how it can support your business.

{{cta(‘ab85071a-d654-4295-bbad-b8e8302eeff7’)}}

The company – Worldwide player in the production of eyewear

Marcolin is a historic brand on the international eyewear scene. The company, based in Longarone (BL), designs, manufactures and distributes eyewear products. Ranked among the world’s leading companies in the sector, Marcolin stands out among operators for the high quality of its products, stylistic skills and manufacturing capabilities, attention to detail and prestigious distribution.

In 2016, the Marcolin Group sold around 13.5 million glasses worldwide, achieving a turnover of about 442 million euros thanks to the work of its 1,773 employees, which is joined by a widespread network of independent agents.

The recent integration of the American eyewear distribution company Viva, thanks to the product and market complementarities with the Marcolin Group, has given rise to an eyewear entity with a strong global presence, in terms of brand portfolio, product, as well as geographical presence on outlet markets.

Today Marcolin has a portfolio of 26 licensed brands in the Luxury and Diffusion segments, in the “view” and “sun” segments. It is positioned in the Luxury segment with some of the most important brands, including Tom Ford, Tod’s, Balenciaga, Roberto Cavalli, Montblanc, Zegna, Pucci and the most recent Moncler and Omega, and in the Diffusion segment with the brands Diesel, DSquared2, Guess, Guess by Marciano, Gant, Harley Davidson, Just Cavalli, Swarovski, Timberland, Cover Girl, Kenneth Cole New York, as well as with other brands dedicated specifically to the US market. Owned brands include WEB and the historic Marcolin.

From the point of view of geographical distribution, the Group has a presence in all the main countries of the world through its direct subsidiaries, or with partnership agreements (joint ventures), or exclusive distribution agreements with major players in the sector.