We interviewed the Supply Chain Director of Molteni Farmaceutici, who told us about the implementation of the APS software used to manage the production of the Tuscan company. Molteni Farmaceutici, based in Scandicci in the province of Florence, wanted to innovate and digitize the process of planning and scheduling production, immediately obtaining great visibility over the medium to long term, sharing plans and other benefits, all within a project of innovation and digitization.

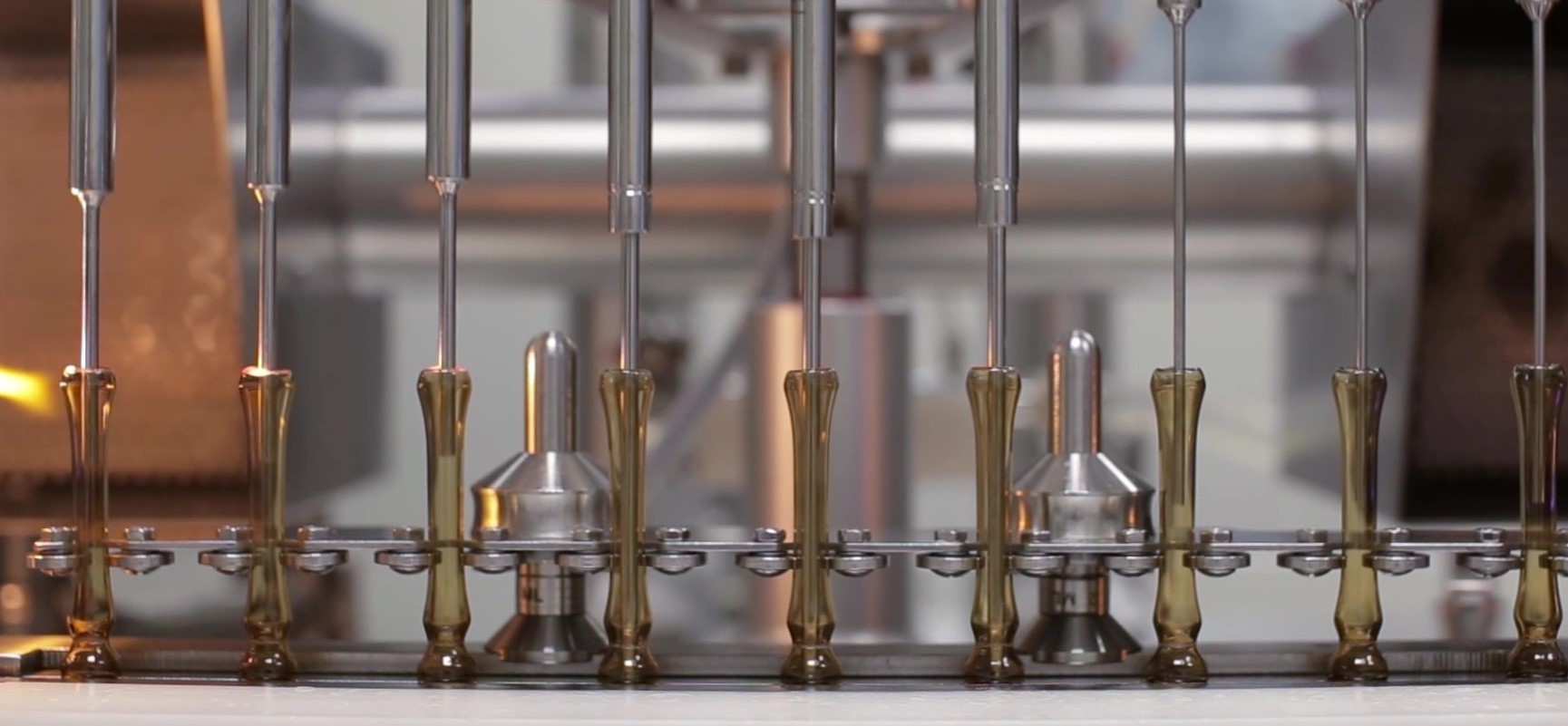

Molteni Pharmaceuticals: drugs for the treatment of pain and addictions

Molteni Farmaceutici is a leader in Italy in the field of pain and addiction therapy, operating in about 40 countries around the world directly or through commercial partners. Over the last 2-3 years Molteni has achieved significant improvements both in terms of productivity (about +16 percentage points of Overall Equipment Effectiveness) and service level. These results are mainly attributable to the work carried out in the Business Process Excellence (BPE) business project, which includes the implementation of the tool for production planning and scheduling, carried out in an advanced manner.

We know that Molteni is now a global player in the pharmaceutical sector, would you like to tell us more about who Molteni is and what it does?

Molteni Farmaceutici is a leader in Italy in the field of pain and addiction therapy, operating in about 40 countries around the world directly or through commercial partners.

Would you tell us about the path that led to the search for APS software?

The scheduling of finished capacity lines is essential to be able to draw up reliable production plans, and consequently to be able to meet the commitments made to customers while optimising production sequences. CyberPlan has allowed us to carry out this task in an “assisted” way, thus facilitating the activities of the planning staff.

How did the APS implementation project take place?

A cross-functional team was set up, involving, for example, Planning and IT. The general user requirements were defined, and consequently the scouting and technical-economic comparison of the main systems available on the market was carried out, and finally we made our choice.

What ERP do you have and how does the CyberPlan solution integrate with the management system in use?

We have SAP. to which CyberPlan is connected through special interfaces that allow you to exchange orders, stocks and sales forecasts.

Would you like to tell us about the Molteni production planning process and any of your peculiarities?

The production planning process in Molteni Farmaceutici partly follows the make to order logic (in a frozen horizon shared with industrial customers) and partly follows the make to stock logic (based on stock monitoring and rolling forecast provided by commercial functions).

Production can be carried out both internally and through subcontractors.

The points of attention are the classic ones of pharmaceutical production, for example compliance with the technical batches registered with the authorities, the optimization of production sequences to limit the number of set-ups, the introduction of variations in printed materials trying to contain obsolescence costs.

Does CyberPlan help you communicate internally between operations and sales and/or externally with suppliers and customers?

There have always been moments of communication both between Planning and Production and between Planning and commercial divisions. Lately we have been experimenting with “stock profiles” periodically extracted by CyberPlan to facilitate the sharing of information on product coverage with other functions.

What are the results and benefits you have obtained so far, from the implementation of the APS software?

Over the last 2-3 years Molteni Farmaceutici has achieved significant increases in both productivity (about +16 percentage points of OEE) and service level. Clearly, these results are not only attributable to the scheduler, but above all to the work carried out in recent years thanks to the Business Process Excellence (BPE) BUSINESS project.

Has the planner’s job changed from before to after?

The work of the planner has not changed significantly, but the tool has changed, which has made it possible to automate some processing previously carried out on spreadsheets.

Which aspects of CyberPlan do you like the most, as a user?

At CyberPlan we like the fact that it is a complete tool, able to support both internal and external planning, both in “make to order” and “make to stock” logic, integrating up to the proposals for the supply of materials. At the same time, we hope that future versions of CyberPlan can be equipped with an even more user-friendly interface, and that some options can be more easily configured by users on their own.

What advice would you give to a colleague of yours who is considering implementing an APS?

The completeness, the simplicity of use, the configurability in autonomy. And a partner able to assist you in a professional way from the development phase to the post-go-live one.

CyberPlan, the APS for planning and scheduling full-capacity production

The important results obtained by Molteni Farmaceutici were also possible thanks to the work of consultants, staff and the adoption of the Advanced Planning and Scheduling CyberPlan tool. Thanks to advanced logics such as finite-capacity scheduling and the high computing power deriving from the database in RAM, APS allows manufacturing companies to plan production in a modern, fast and shared way. Learn how to implement this tool in your company.