We interviewed Mirco Cattin, production manager of M Pumps, a company based in Rovigo that has innovated methods and processes to manage the production of process pumps. Foresight and ambition have driven the company to equip itself with complementary software: the Manufacturing Execution System Opera MES and the Advanced Planning and Scheduling CyberPlan APS, which have allowed a modern management of the production department.

M Pumps, over 40 years of experience and innovation

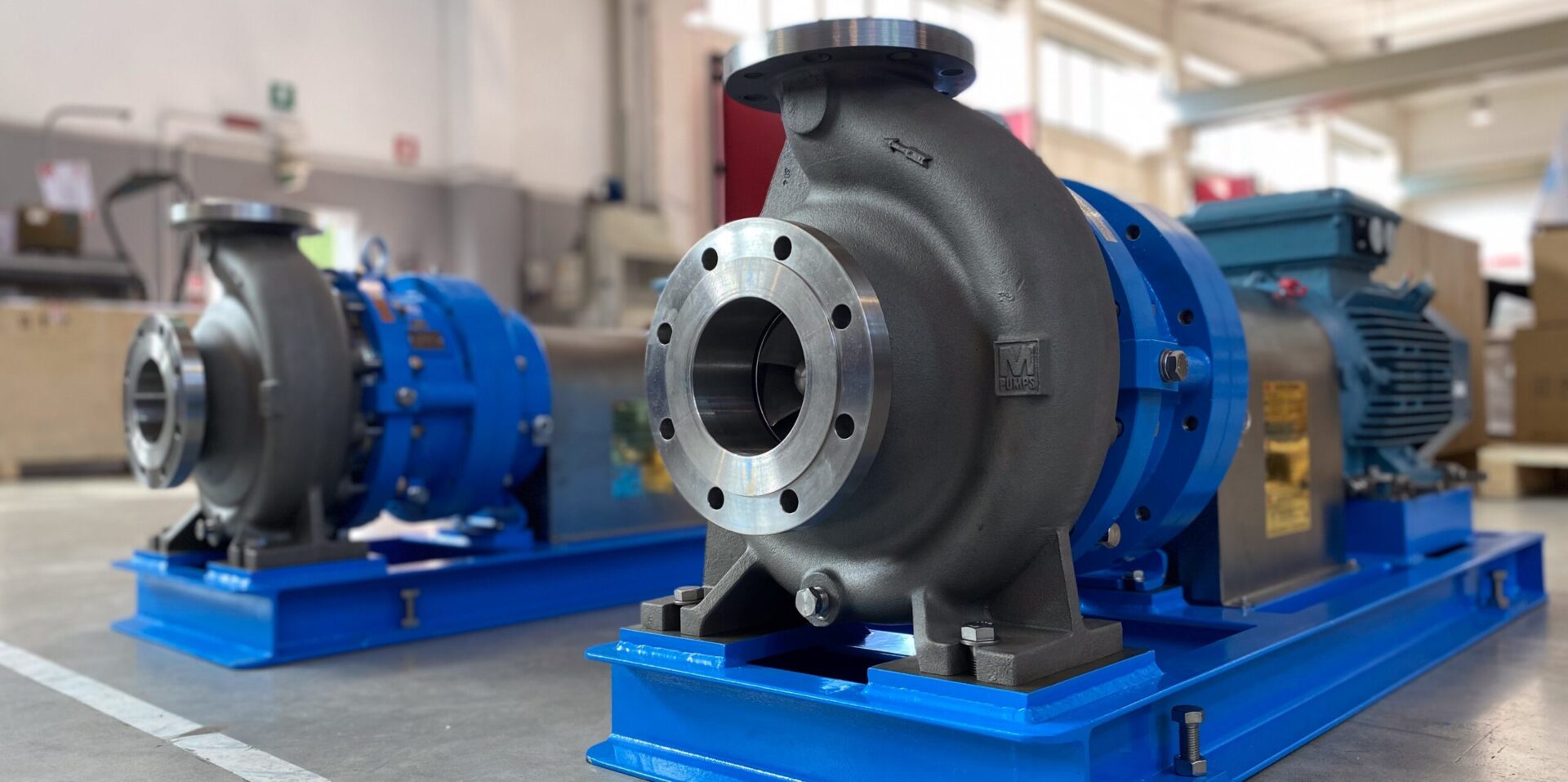

M Pumps is a company based in Corbola in the province of Rovigo that has been operating in the process pump market for over 40 years. It offers a wide range of machines, both magnetically driven and mechanically sealed. The machines made by M Pumps are largely intended for the oil and gas market and for chemical and pharmaceutical processes, as well as some treatment.

The engineering office of the Venetian company, composed of highly trained personnel, meets the needs of the demand of the various projects. M Pumps in fact mainly produces custom machines, which it designs around the specific needs of the customer and the purpose of the case.

Willingness to grow, managing new complexities

The project began in 2009, a period of strong growth and development for M Pumps, two aspects that have also determined the need to equip themselves with the right tools to manage the production department.

“A structured APS was needed to manage the various dynamics: M Pumps is a relatively small company but has all the dynamics and complexity of a large company being very dynamic and with large and varied product portfolios” Mirco Cattin

In fact, there are over 33,000 items in the registry, the machines in the range reach 9,000 configurations and therefore the MRP was and is a fundamental aspect in the production of M Pumps.

At the time, a simple MRP included in the management system was used, with this tool the bills and needs exploded; there were some difficulties despite the codes were less and the variability of the product was lower.

The foresight combined with the desire to have a MES and an APS have led M Pumps to be the master of great growth, not only in turnover but also in complexity and variety of the offer. The choice proved to be strategic and played its part in contributing to the remarkable growth of recent years and in managing the changing scenarios of recent years.

However, M Pumps’ supply chain has experienced the criticalities of the supply chain as it imports materials from all over the world to make its products, which has led, for example, to being affected by the problems of the Suez Canal, managed promptly by postponing some customer orders and internally rescheduling incoming materials.

Complete planning and scheduling, aimed at achieving the objectives

M Pumps’ great attention to the customer has led it to work mainly from an MTO perspective, however some product families are made by adopting the MTS logic. Based on data obtained by consulting a CyberPlan dashboard, M Pumps analyzes the trend of some product families in the previous period and decides whether to manage certain codes, sizes and families such as MTS so as to have products ready for the following year and have a shorter lead time. The product range of M Pumps is in fact quite heterogeneous, in fact if the smallest pump is about 20 centimeters long, the largest reaches up to 12 meters and if the machines pump mainly fluids, some manage both fluids and gases, even at the same time, and not only in oil and gas but also in the medical, cosmetic or pharmaceutical fields.

Not only internal production, but also that of the work account is planned by M Pumps with the CyberPlan APS tool. The planning tool is not used directly but thanks to the use of export it is possible to effectively communicate expiration dates, delivery dates and various reminders to suppliers. In fact, CyberPlan is used by different departments: planning, purchasing, supply chain.

A further use of CyberPlan is simulation. For many years M Pumps has used a price list that reported fixed lead times, but recently it has switched to a daily simulation, based on orders placed the day before.

“The delivery date now comes out of the MRP, not a standard lead time handed down over the years. In this way we can be more precise and better manage the capacities and the amount of hours of the various departments as well as better mix the various productions.”Mirco Cattin

Thanks to the work done by M Pumps and its people in arranging data, today tools allow you to focus and support business objectives and to give yourself increasingly challenging goals. The software solutions allow M Pumps to have the pulse of production even while in the office and to have reliable simulations.

“CyberPlan helps us achieve our goals because it is a very fast processing system and allows us to make very reliable choices and simulations.” Mirco Cattin

Results and objectives achieved thanks to the work of people

M Pumps manages its production keeping several indicators under control. Some of these KPIs are:

- On-time Delivery, increased by about 10 points in the last 5 years.

- Goods ready for collection

- 0 accidents

- Yield of the various production trends, that is, the number of work orders that are completed on time, as the difference between budgeted and finalised

In particular, for this last aspect, an automatic system has been created that reports every day which operations have exceeded the expected times in excess and which in default so as to have evidence of any problems or errors in predicting cycle times, which can then be corrected, if necessary.

The aforementioned strategy of managing some products with the MTS logic then made it possible to increase the sales volume of certain product families. The careful analysis carried out by the people of M Pumps has made it possible to decide which product lines to produce for the warehouse and to be rewarded by the market by increasing sales and optimising production.

Finally, users declare that they particularly appreciate two aspects: customisation and completeness.

“I still haven’t found something I can’t do with CyberPlan. Only with a small configuration or with a little training can I find all the possible information regarding the production process. There is practically no limit.”Mirco Cattin

Technical and consultancy support on solutions during business growth

The M Pumps projects were carried out by the staff of the Rovigo company thanks to their commitment and the will of the management; Link Management supported them from a consultancy point of view. The collaboration has now lasted for over ten years and has led to the implementation of both the Opera MES and CyberPlan APS solutions.

“We have an excellent relationship with their most established technicians who support us both remotely and in the company, even in a short time” Mirco Cattin

APS, ERP and MES

The system chosen by M Pumps and implemented by Link Management involves the use of different software solutions for production management. Further benefit derives from the excellent integration between these solutions, which allows a better dialogue and a faster exchange of data.

“There is a triangulation between the three systems that work in a very harmonized way and there is a very good connector, there are no problems.” Mirco Cattin

Production information and company data are stored in the Meta management system of Serenissima informatica that dialogues with the Opera MES and CyberPlan APS solutions.

In particular, Opera MES detects and transmits all the progress of the processes, as well as the discharges to the warehouse and the final results within the individual work orders. In addition, the data are used for some analyses, after being extracted with Qlik they are in fact used to create analyses and graphs that are then presented and shown in production.

CyberPlan analyzes this data every hour and provides updated values: progress status of the various work orders, various productions, declarations of the personnel working in the workshop.

Link Management author of the M Pumps project

The M Pumps project was carried out by Link Management, a long-standing Cybertec partner who also installed Open Data’s Opera MES and offered a business consulting service. In particular, Link Management has better integrated the solutions and adapted the CyberPlan tool around the individual company, allowing to create some useful customizations to simplify calculations and analysis for the planning department.

CyberPlan, the APS for planning and scheduling full-capacity production

The important results obtained by M Pumps were possible thanks to the work of M Pumps staff, Link Management consultants and the adoption of the Advanced Planning and Scheduling CyberPlan tool together with Opera MES. Thanks to advanced logics such as finite-capacity scheduling and the high computing power deriving from the database in RAM, APS allows manufacturing companies to plan production in a modern, fast and shared way. Learn how to implement this tool in your company.