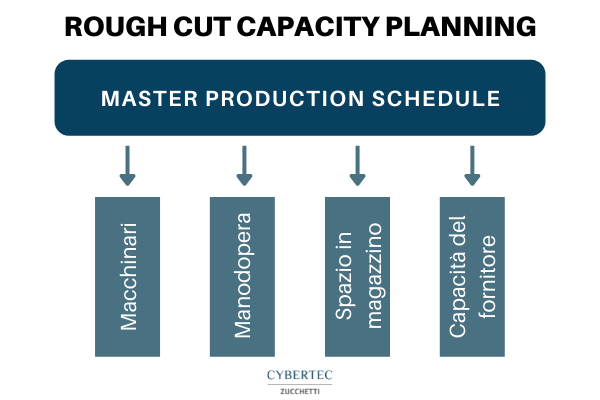

Rough Cut Capacity Planning, or RCCP, is a rough planning of production capacity that is used for major resources, such as supplier capacity, workforce, plant and machinery, to make a first production schedule, which is subsequently improved by more advanced techniques and more complex calculations.

Whatis RCCP?

Rough Cut Capacity Planning, or RCCP, is a type of calculation aimed at verifying that the available production capacity of a manufacturing company is sufficient to meet its requirements in terms of production capacity required by the main programs.

Who uses Rough-Cut Capacity Planning?

The RCCP is a long-term plan capacity planning tool that is used by different business functions to balance required and available capacity and to negotiate changes to the overall program and/or available capacity. It is therefore often used, in addition to the planning office and Supply Chain Management, also by the sales and purchasing office and sometimes also by company management.

This versatility and usefulness is given by the fact that with the RCCP it is possible to modify the production plans by changing the dates of the main program and increasing or decreasing the quantities of the main program. You can change the available capacity by adding or removing shifts, using overtime or contract work, and adding or removing machines.

How does Rough-Cut Capacity Planning work?

The RCCP is a production capacity planning that does not take into account planned material arrivals or available inventory quantities in the calculation of capacity requirements. These rough capacity plans are therefore a statement of the capacity required to meet gross production requirements.

Using the RCCP to validate master schedules against key and critical assets before using the planning process to generate detailed MRP plans ensures that realistic and achievable master planning is used to guide the planning process.

Rough Cut planning can be performed at two levels:

- Use a routing-based RCCP if you want to plan the approximate capacity per resource. In this case, the requested and available capacity is indicated in hours per week per resource.

- Use a rate-based RCCP if you want to plan the approximate capacity per production line. In this case, the required and available capacity is indicated by the production rate per week per row.

If you want to use an RCCP, but want to limit the process to key or critical resources, you can define selected resource groups and review RCCP plans only for specific resource groups.

An example of RCCP

To analyze a concrete case of RCCP, let’s consider the example of a shoe factory that produces two items, boots and sandals. Before starting the production of the pieces, an MPs calculation is made and the amount of material required and the number of hours of work required are calculated.

An RCCP also includes a graphical representation of the staff hours needed to perform the work; the units required; the days needed to complete the task; and the amount of material to be purchased. However, this chart does not take into account details related to inventory management or receipts scheduled to arrive later.

So, an RCCP is simple, intuitive, and similar to organizational planning to track requirements with a rough estimate.

CyberPlan RCCP Software

With CyberPlan you can plan long-term production easily and intuitively, transforming forecasts into production plans that meet long-term demand needs. CyberPlan helps you answer key planning questions to anticipate potential problems. The powerful algorithms that characterize the software allow you to make accurate sales forecasts and obtain optimized production plans.

Learn how to integrate RCCP planning into your business

You can improve the methods and tools used daily in your company to plan and schedule the entire production, adopting the latest and latest software solutions capable of relieving planners from repetitive and low added value calculations. An APS solution, in addition to relieving operators of these operations, also allows the company that adopts it to improve vital indices such as service level, production lead time or inventory levels. Ask an expert right away how you could improve your planning by integrating solutions into your systems that can improve competitiveness.