With the increase in the demand for customisation and the expansion of mass customisation, contract productions are assuming an increasingly important role in the production landscape. The demand for customized products is growing in a market that is changing rapidly and is becoming increasingly demanding in terms of reliability, speed and flexibility.

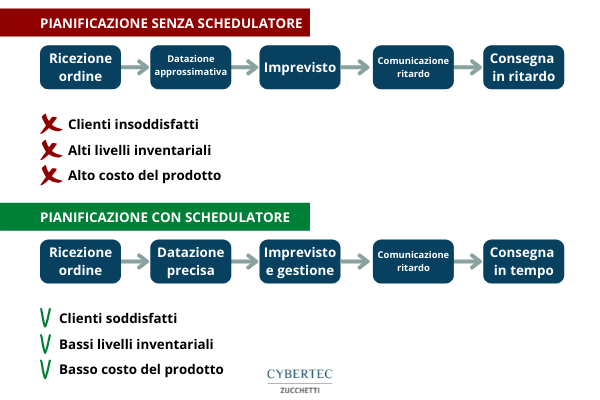

Contract productions are now managing their natural complexity alongside ever-higher performance objectives. Controlling and managing production in the best possible way therefore becomes the key to competing and responding to this market. Equipping yourself with inadequate tools in this period can easily and suddenly lead to severe delays in deliveries, numerous missing ones (despite high WIP values) and strong inefficiencies, especially in terms of On-Time Delivery. Equipping yourself with the right tools will put the company in a position of strong advantage over companies that will not have caught the changes and challenges of the market in time.

Production on order

In contract production, the entire production cycle is customer-oriented and therefore managed around it. Only after receipt of the order does the raw material supply cycle, production processes and possibly the engineering design begin in the case of ETO (Engineering to Order).

- Delivery dates – Customers need reliable delivery dates.

For this reason, sales ask the planning department to provide dates on which they can rely already in the negotiation phase. This may not be so immediate in a context where the product has yet to be engineered and designed. These dates must then be respected during the entire production cycle of the order in order to comply with the OTD (On-Time Delivery). To do this, it is necessary to have visibility of all constraints: capacity, resources and materials. - Lead time – The delivery dates promised to the customer must therefore be respected but companies must at the same time guarantee the shortest possible lead time. To reduce lead time, it is essential to optimise internal production processes by saturating machinery and resources. Achieving the best organization of resources and processes often results in increased planning complexity. The aspects that are essential to achieve the best organization are the calculation of factory constraints, communication and coordination between departments.

- Productivity – Productivity and cost reduction are achievable thanks to the saturation of machinery and resources. To do this, it is therefore essential to have maximum visibility of all the constraints of the supply chain, or bottlenecks.

- Reactivity to unforeseen events – An ETO product is by its nature easily subject to multiple variations and changes that often occur during construction. Reacting to changes and other unforeseen events that may occur in the different phases of the production cycle is therefore crucial for a company that produces on order.

To achieve all these results, it is therefore essential to have tools that can give maximum visibility to the company’s supply chain, to align resources with market demands. Many companies are convinced to plan with their management systems, for which they have invested time and money, but in most cases this is not the case. This is often noticed when the level of On-Time Delivery has fallen, the costs in the warehouse have risen and in production it is a continuous emergency work.

Does your company plan production orders with the management system?

Many companies that produce on order, start by planning production on the company management system, and then move on to planning on Excel and Project (in this regard you may be interested in the article “5 risks of planning production with Excel“). These two tools are used for planning to increase flexibility and make their data in graphic format and therefore easier to understand. But at the same time they allow to process only a part of the data necessary for the planning on order and are not integrated either into the management system or between them. These shortcomings create enormous manual work over time, leading to approximate results and unable to align the activities of the various areas (technical department, purchasing, production and sales).

Over time, these tools to support planning processes lead to work for emergencies causing a drop in on-time delivery and despite an increase in costs in the warehouse, missing materials and therefore machine downtime begin to become increasingly frequent. Poor visibility of production makes the planning team unable to make effective decisions, with the risk of serious emergencies involving costs and delivery delays.

These difficulties can be effectively eliminated by giving your planning department the right tools that allow you to have full visibility of production, working on all the necessary data while remaining integrated into your management system. The solution that has proven to give the best management and control capabilities for contract production is based on the use of an Advanced Planning System (APS).

Advanced Planning System: visibility, power and flexibility to ERP

Today it is possible to greatly improve the governance capacity of companies operating on a contract basis by extending the capabilities of the ERP used with an APS solution.

APS is a software application that supports the decision-making process for the creation of production and purchasing plans. Through advanced mathematical algorithms, it allows you to simulate the entire factory, allowing you to anticipate possible problems and react in time to solve them before they occur. APS is the tool that allows the planner to:

- Dating orders in real time and reliably to maintain a high level of On-Time Delivery;

- Manage resource loads to maintain a high level of saturation while maximizing efficiency;

- Align production with purchases to avoid shortages and balance warehouses with actual production needs;

- Preventively identify critical materials and bottlenecks;

- Reduce production lead times.

Plans generated by an APS are of high quality and require much less manual activity by the planner to generate and maintain.

On-time delivery KPI

On-Time Delivery performance refers to the calculation of the ratio between the lines of the sales order shipped by the delivery date requested by the customer (or promised to the customer) and the total number of lines of the sales order. Usually this value is expressed as a percentage and can be calculated over different measurement periods.

CyberPlan: Cybertec’s Advanced Planning System

CyberPlan is a powerful and innovative APS that since 1991 has supported the planning and scheduling of the production of thousands of companies around the world: companies ranging from small-medium enterprises typical of the Italian territory to large multinationals over the ocean.

Every day these companies face unforeseen events and changes in production scenarios thanks to the APS solution, guaranteeing management compliance with fundamental KPIs such as On-Time Delivery or the material turnover index.

Cybertec’s solution has been officially certified by the DDI, but it doesn’t stop there. CyberPlan was in fact certified as DDMRP software at its first evaluation, which happened in very rare cases and was publicly praised by Chad Smith, founder of the DDI. Obtaining the certification with full marks, at the first evaluation, demonstrates the goodness of the solution and the maturity of the logic and techniques it uses. It is a guarantee of operation and result that allows you to choose CyberPlan with the security of a serious and professional partner.

Success stories in contract production

Many companies that produce on order use CyberPlan to increase competitiveness in the market. Companies such as Ansaldo Energia, General Electric (baker Hughes), ABB, Siemens Transformers, Breton, Cefla and many more. Find out how to achieve On-time delivery in contract production by downloading the free guide HERE.