We all know that for ETO (Engineer To Order) and MTO (Make To Order) type productions, engineering is increasingly becoming a critical department of the production chain. Surprisingly, while engineering is the most critical department in ensuring and maintaining delivery dates, often its planning is not as tightly integrated with the production plan. Usually, a combination of ERP tools, project planning tools, Projects and Excel sheets that have poor integration with each other is used. The results of such planning are typically far from satisfactory. The sales department requires the production to provide reliable delivery dates but the production does not have the visibility of the engineering load and hardly manages to have visibility on a delivery date that is reliable. Engineering, or technical department, is therefore under pressure and tends to move many times from one project to another creating waste and tends to plan based on experience without having clear visibility of the loads and without interacting effectively with purchases and production.

Difficulty in synchronizing production with the technical department

The difficulty in creating integrated plans, synchronizing production, purchasing and product engineering creates a series of difficulties:

- Firstly, production lead times increase, as does their variance. Not synchronizing purchases, especially of critical materials, with the technical department and not having visibility into production leads to longer times between activities and the lack of control tends to fluctuate their variance.

- The increase in lead times causes an increase in WIP (Work In Progress).

- The little control on delivery dates and the poor integration of production with the technical department does not give visibility on the delivery dates to be given to the customer at the time of negotiation. The dates communicated to customers are hardly maintained, causing delays in deliveries and a low on-time delivery;

- Variance generates unstable plans whenever priorities are changed;

- Changing priorities destroys productivity;

- Reducing productivity when resources are already saturated creates a vicious cycle that increases loss of control.

Finally, non-integrated tools make it difficult to understand and see problems in time as well as promoting the natural aptitude of departments to be isolated in silos.

It is possible that the real reason why companies do not plan all production departments in an integrated manner is complexity. Most companies simply strive to plan production. Adding product engineering to planning would increase complexity, far beyond their capabilities.

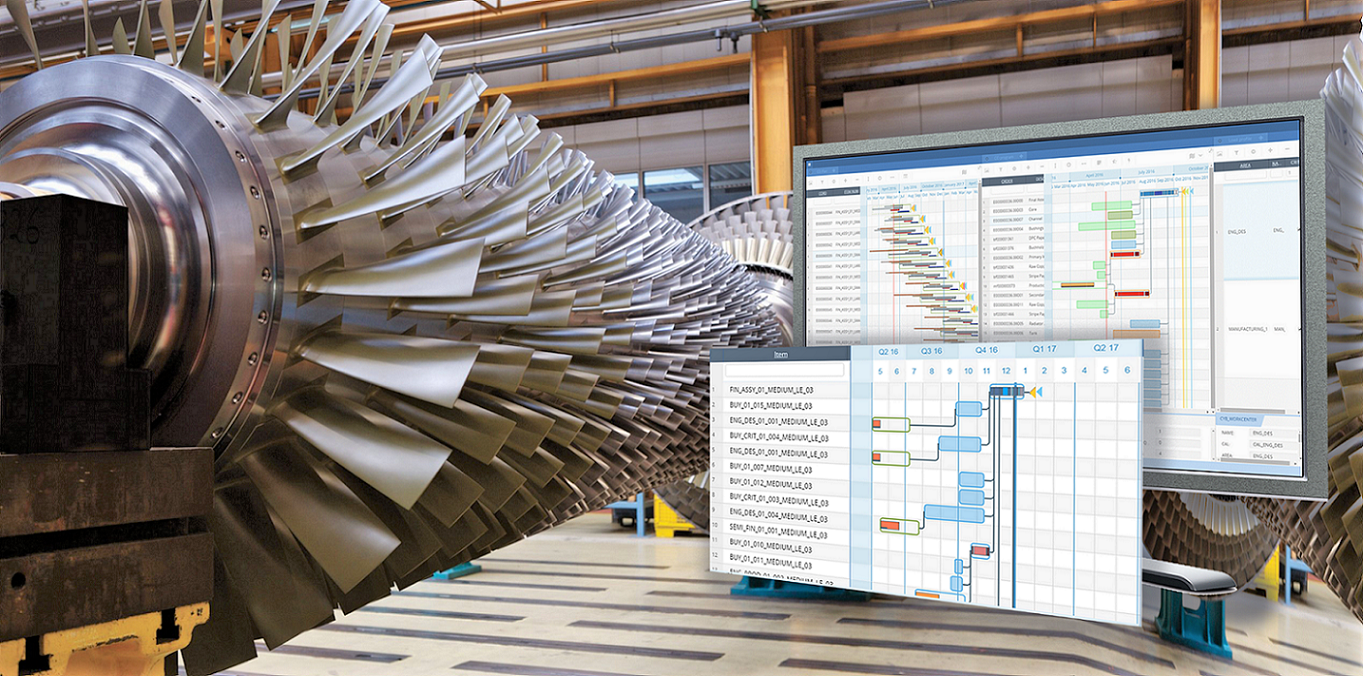

CyberPlan, the integrated tool for planning and scheduling production, purchasing and engineering

Customers who have implemented CyberPlan usually realise, after a short period, that they have immediately saved planning capacity and that it would have been and still be possible to use it to include the engineering part of production as well. They often discover with surprise that there are some “hidden pearls” within CyberPlan, designed specifically to allow them to integrate production planning and engineering plans.

With these potentialities, it is easily possible to add engineering activities alongside those of production and keep engineering plans synchronized and feasible, increasing the capabilities of the human being, thus allowing him to handle more complex problems.

Managing engineering, purchasing and production tasks at finite capacity (thus taking into account production constraints) and at the same time being able to make informed decisions, leads to a series of benefits. First of all you get a stable plan, engineering lead times are reduced as well as their variance.

It is also interesting to note that a substantial increase in the throughput of the engineering itself is also obtained. This increase is not only the effect of the reduction in interruptions of work orders. The benefit in question, in fact, refers to a best practice in engineering planning enabled by one of the most interesting features of the scheduler for the engineering department. This is the possibility of limiting the maximum number of simultaneous activities open for each engineer.

We all know that if we examine an engineer’s productivity curve based on the number of simultaneous tasks, we usually find a weakness. Assuming that for a particular engineer the weak point is four, having more or less four simultaneous open tasks will reduce productivity. Engineering planning with a focus also on limiting competing activities is the easiest way to improve the throughput of the engineering department.

Finally, increased visibility on the floor allows the technical manager to have a better understanding of how the work is progressing and to make the most appropriate and objective decisions. Having all the information in real time allows you to cut the path continuously while minimizing disruptive priority changes.

Benefits of the integrated system between production, engineering and purchasing

Having the possibility to plan production in an integrated way with the technical office, purchases, negotiations and orders, allows Engineer To Order companies to enjoy important benefits. With the use of CyberPlan for production planning and scheduling, companies have had significant benefits, such as:

OPERATING BENEFITS:

- Greater speed of decision making processes;

- Better organisation of resources;

- Ease in identifying critical issues in Engineering processes;

- Lead time reduction and their variance;

- Reduction of time for the planning process.

ECONOMIC BENEFITS:

- On-Time Delivery increase;

- Reduction of WIP;

- Increased efficiency.

IT BENEFITS:

- Centralization of data in the company ERP;

- Elimination of offline systems such as Excel and Project.

See for yourself how CyberPlan can support you in creating integrated production plans across engineering, manufacturing, and purchasing.