The story of how Vimar S.p.A. reduced the quantities in stock while eliminating the risk of product shortages and reducing set-up times, in an interview with Eng. Christian Castellan, responsible for production planning.

Leader in the production of electrical and electronic equipment

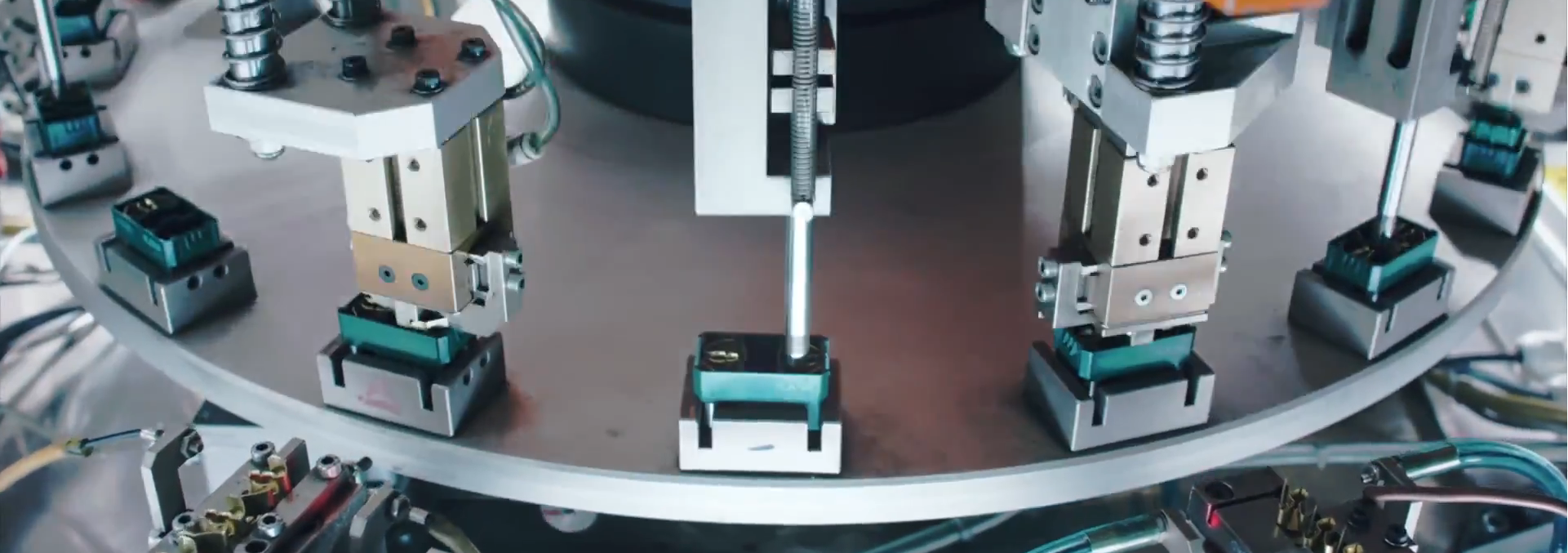

Vimar is a leader in the production of electrical and electronic equipment, in particular civil series, Home & Building automation systems, video door entry systems, CCTV (Closed Circuit Television) and gate automation. It is active mainly in Italy, but it is also present with production and commercial offices at an international level.

Achieve complete supply chain governance

Before Cybertec, planning was carried out through the ERP, which only partially covered the planning and scheduling needs of a complex reality such as that of Vimar.

The main requests concerned:

- Poor visibility of planning workloads;

- Long times for the elaboration of the production plan;

- Impossibility to time the activities in a structured way between the various functions;

- Elevated warehouses .

There was therefore a need to have a tool capable of providing a complete view of the main production plan, and to use specific variables to govern the Supply Chain at various points, formulating a robust and more performing planning.

Many companies, lacking an effective planning and scheduling system, do not have visibility into the production and supply chain. This leads to an increase in the quantities in stock and to having poorly balanced warehouses which in turn cause on the one hand the presence of missing and low turnovers, on the other the risk of obsolete products. Warehouses of this type lead to difficulties at different company levels: the low turnover of the warehouse leads the CFO (Chief Financial Officer) to find himself with blocked capital that cannot be invested in anything else, the Supply Chain Manager finds himself with low service levels caused by delivery delays and finally the Operations Manager finds himself having to block production due to the sudden occurrence of shortages, which causes resource inefficiencies.

CyberPlan: the advanced software for production planning and scheduling

The careful software selection carried out has rewarded CyberPlan as the best solution, especially for a complex reality such as that of Vimar. Completeness of the processes covered (from planning to scheduling), overview of Sales and Operations Planning, flexibility of integration, processing speed and the high ability to simulate different scenarios to make decisions, are the mix of potentialities that have brought CyberPlan to the top of the ranking.

Operations and business results

By equipping itself with CyberPlan APS, Vimar has managed to have full visibility of the supply chain, aligning everyone and being able to completely eliminate stock outs and reduce stock, leading to considerable benefits thanks to a realistic and optimised production plan.

But not only that…! The processing of the production plan is now faster and more robust, and the company is able to create countless feasibility analyses by intervening on any variable of the plan before making it operational. The possibility of simulating various production scenarios, intervening on any variable of the plan, allows you to make effective decisions quickly.

Thanks to the speed in finding previously dispersed information, planning and scheduling activities have been structured and a high degree of autonomy and control is thus provided to users in the performance of their functions.

The company now plans its production capacity well in advance, so as to optimise the resources needed to deal with the seasonality of product sales. Overtime shifts are avoided, both internally and for external supply partners.

After a year there was a reduction in stock, the incidence of set-ups in the departments fell considerably and stock-outs were almost completely eliminated.

“After a year we had an interesting reduction in stock, the incidence of set-ups in the departments dropped considerably and stock-outs were almost completely eliminated. Today, thanks to CyberPlan, we are able to plan a levelling of production capacity well in advance, to optimise the resources needed to deal with the seasonality of product sales. We avoid resorting to after-hours shifts, both internally and for external supply partners.”

Eng. Christian Castellan – Production Planning Manager – Vimar

Request a demo >

See for yourself how to plan and schedule production in an advanced way and achieve goals like Vimar. Request a free demo:

{{cta(‘ab85071a-d654-4295-bbad-b8e8302eeff7’)}}