The story of how Caleffi was able to improve the management and control of resources and inventory levels thanks to the CyberPlan tool and its standard integration module with SAP, in an interview with the group operations director, Mr. Giorgio

Milan.

The CyberPlan advanced planning and scheduling solution features a standard integration with the SAP management system. In fact, Cybertec’s APS solution enhances management by eliminating the Excel used for planning, centralizing information and sharing it with all departments that need to dialogue with each other.

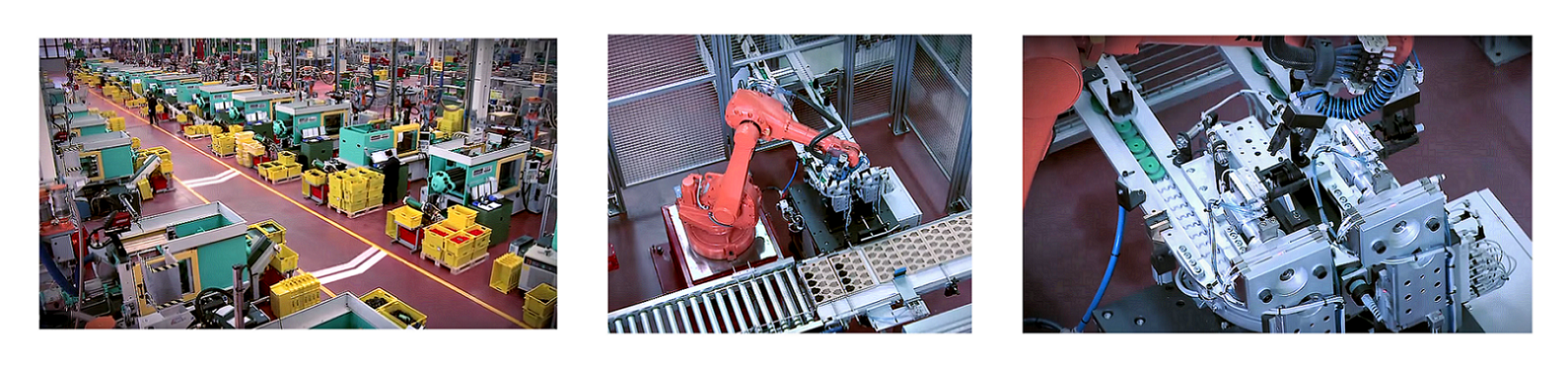

The Caleffi company, production of sanitary solutions

Caleffi is a leader in the development and production of components for heating, air conditioning and hydro-sanitary systems, heat accounting systems and specific components for renewable energy systems. It has over 1,000 employees distributed between the Italian headquarters and foreign branches, markets in over 70 countries and has a turnover of over 300 million euros.

Optimise production to manage the increase in mix

The continuous search for new markets has implied over the years a strong expansion of the product range with a consequent increase in the production mix that has led the company to currently have 7,000 finished product items.

Below is the interview with the Group Operations Director, Mr. Giorgio Milan, and the Group Planning Manager, Mr. Filippo Portigliotti.

“The sharp increase in complexity has made a production structure by product line as unsuitable as the organization of our production was until a few years ago. The consequent shift to a job-shop model (about 200 work centres are currently managed on 2 plants for the mechanical processing, plastic moulding and assembly departments) has clearly highlighted the need for greater control of the workloads deriving from the production plan and better synchronisation in the planning of materials in order to contain the inventory levels of semi-finished products and the total crossing times, while maintaining the already excellent level of service.”

Availability of materials and production resources

“Aware of this need, we have turned our efforts towards defining a planning process that takes into account the availability of materials and production resources in the creation of the production plan, in order to obtain reliable dates about the stock availability of the items. In the company we used a production scheduling solution that, however, had the enormous limit of not managing appointments between materials. So we decided to organize a software selection that would allow us to understand the state of the art of production planning solutions.”

Departmental software for production planning and scheduling

“During the selection process, which lasted nine months, we had the opportunity to evaluate six different products. At the end of this process, the choice fell on Cybertec’s CyberPlan APS because it proved to be the only one to cover all planning processes, from the medium term to detailed scheduling, in an integrated manner within a single product. It also has a standard SAP integration module that has allowed us to greatly reduce the risk related to interfacing, which is always a critical factor in these projects, as well as allowing us to considerably reduce the commitment in terms of internal IT resources. Finally, Cybertec stood out for the consultancy approach taken from the early stages of sales, proposing itself as a strategic partner, which allowed us to make a technological choice that took into account a medium-term evolution of our planning process.

The CyberPlan introduction project was structured in several phases, the first of which allowed us to miss an element of high criticality already after a few weeks: the extraction of the data contained in SAP. This phase, which experience has taught us to be critical and able to make a difference, was in fact profitable, reliable and highly performing. During the project, there was a need to manage some “custom” data (that is, specific to our company), which was managed with great competence and speed by the Cybertec team. The project covered the finite capacity planning and scheduling processes, up to the publication of the work plan directly on each single station, with about 150 active stations and an almost real-time synchronization with the data collected from the field. The exceptional competence, availability and professionalism of the Cybertec team in support of the project has allowed us to adopt the best solution for our specific needs.”

Results

“We appreciated an improvement in the ability to control and manage production resources, an improvement in inventory levels, accompanied by an increase in the already excellent level of service to the market. The control of the missing items has been drastically simplified and is now highly effective and of immediate use.”

“CyberPlan proved to be the only one to cover all planning processes, from mid-term to detailed scheduling, in an integrated manner within a single product. It also has a standard SAP integration module that has allowed us to greatly reduce the risk associated with interfacing.”

Engineer Giorgio Milan – Group Operations Director – Caleffi

Request a CyberPlan Demo >

See for yourself how to plan and schedule production in an advanced way, enhancing the SAP management system and achieving objectives such as Caleffi. Request a demo:

{{cta(‘ab85071a-d654-4295-bbad-b8e8302eeff7’)}}