Lima Corporate, a leading company in the production of orthopaedic solutions, has grown by an average of 15% every year since 2009 and has reached the threshold of 200 million in turnover. Foresight, intuition and innovation have been the key to this success, allowing Lima Corporate to structure itself with appropriate processes and tools. Among the various projects, the implementation of CyberPlan, the Advanced Planning and Scheduling system that allowed the company to structure and govern the planning and scheduling processes while maintaining control of a strongly changing production, was fundamental. Fabio Coccon, Supply Chain manager of the company, tells us about this path of growth and success that has seen the research, implementation and use of the CyberPlan software solution.

What led you to look for production scheduling software?

Before the implementation of CyberPlan we did not have an APS, we had a very raw MRP that relied on the management system and that did not meet our needs.

In those years the company was beginning to grow and so were the needs to structure the processes more, to the point that it had become extremely important to have a tool that simplified production planning and that did so using precise and structured data. In Lima, we realized that it would be almost impossible to move forward without it.

From there we started looking for an Advanced Planning and Scheduling software and a selection began during which an internal team of 5 people carefully selected and evaluated the various proposals, also making use, for example, of practical use in companies. As a result of this process, the software selected by the team was CyberPlan.

How does Lima Corporate plan production?

We use CyberPlan for the explosion of needs and therefore for both the generation of purchase and production proposals as well as for the planning of warehouse deposit dates. These proposals are forwarded to the purchasing department, which transforms the purchase request into a purchase order, ensuring that the materials arrive on time. The production proposals are transformed into an internal production order. CyberPlan provides the theoretical payment dates of both orders in production and those theoretical, i.e. not yet released.

What results have you achieved from the implementation of APS?

CyberPlan helped us manage business growth, without this tool it would have been impossible to achieve those results. I wonder how it was possible to work before, without the APS CyberPlan. In recent years, we have focused on performance improvement objectives through the optimization and reduction of warehouses and the reduction of lead time. Surely CyberPlan was one of the tools that contributed to achieving these results.

What aspects do you like most about CyberPlan?

The amount of information contained and accessibility to it. In fact, CyberPlan gives visibility to a whole series of useful information, and all this without having to access the management system: I have everything in CyberPlan and I access it quickly and easily. It is accessible and usable.

Another positive aspect is the ease with which we have configured CyberPlan around our needs over the years together with Cybertec consultants. Operating in a market with rather peculiar characteristics, we had to adapt some aspects of APS. CyberPlan allows us to manage all the non-standards we have, with extreme flexibility; it has proven to be very flexible and at the same time solid.

Lima Corporate, production of orthopedic solutions

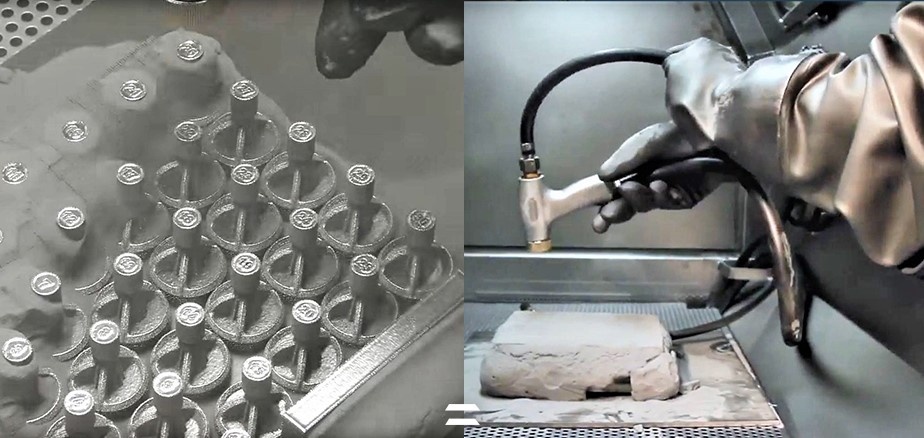

LimaCorporate is a global company that manufactures medical devices that offer reconstructive and fixation orthopedic solutions to surgeons facing the challenge of improving the quality of life of their patients.

Based in Italy, LimaCorporate is committed to developing innovative products and procedures that allow surgeons to select the ideal solution for each individual patient. Lima’s product range includes primary or overhaul systems for large joints and complete end solutions including fixation.

Orthopaedic solutions use innovative methods and technologies, such as 3D printing, and are sold globally thanks to their presence in over 40 markets.