Planning and controlling material flows and production processes are usually considered as two crucial aspects for the success of a manufacturing company.

Over the past 60 years, both academia and industry have gone to great lengths to design and develop effective approaches and methods for production planning and control. This is due not only to the importance of this process, but also to the fact that the methods and approaches of how to plan and control production change over time, in line with changes in customer needs as well as the environment and technology.

How production process management systems have changed

Birth of MRP systems

The first production process management systems were MRPs (Material Requirement Planning), systems for planning material requirements. The first MRPs appeared in the mid-1960s and among the main authors who supported it are the most famous: Joseph Orlicky and Oliver Wight.

Since the 1970s, MRP has also begun to spread thanks to an “MRP crusade” conducted by APICS that led to an even greater spread in the following years. Joseph Orlicky, a supplier of MRP systems, estimated that in 1971 there were about 150 MRP systems. By 1975 some 700 had been implemented and in the 1980s materials planning software became extremely widespread.

In the 1970s it became clear how materials and processes were not the only resources needed to achieve good planning. At that point the MRP, which had benefited from the advances made by hardware, began to expand and include all production resources in addition to adding other information such as demand, sources of supply, cash-flow analysis, sales forecasts, etc. The new MRP became known as Manufacturing Resource Planning, or MRP II and supplanted the previous one that planned only materials and production.

The shift to more advanced planning systems

MRP was a real revolution and between the 60s and 80s it was considered an advanced and innovative feature that automated processes that previously had to be done by hand. However, with the advancement of technology, what is considered cutting-edge also changes and so does the speed and automation of processes. During the 1990s, ERP systems that absorbed MRP systems spread and created a niche of advanced systems that were later defined as Advanced Planning & Scheduling systems. APS systems were born in the 1990s but began to spread towards the late 2000s as planning required greater performance and speed. Only in recent years have APS managed to capture the attention of experts such as APICS and Gartner.

Italy is a pioneer of advanced planning and scheduling systems

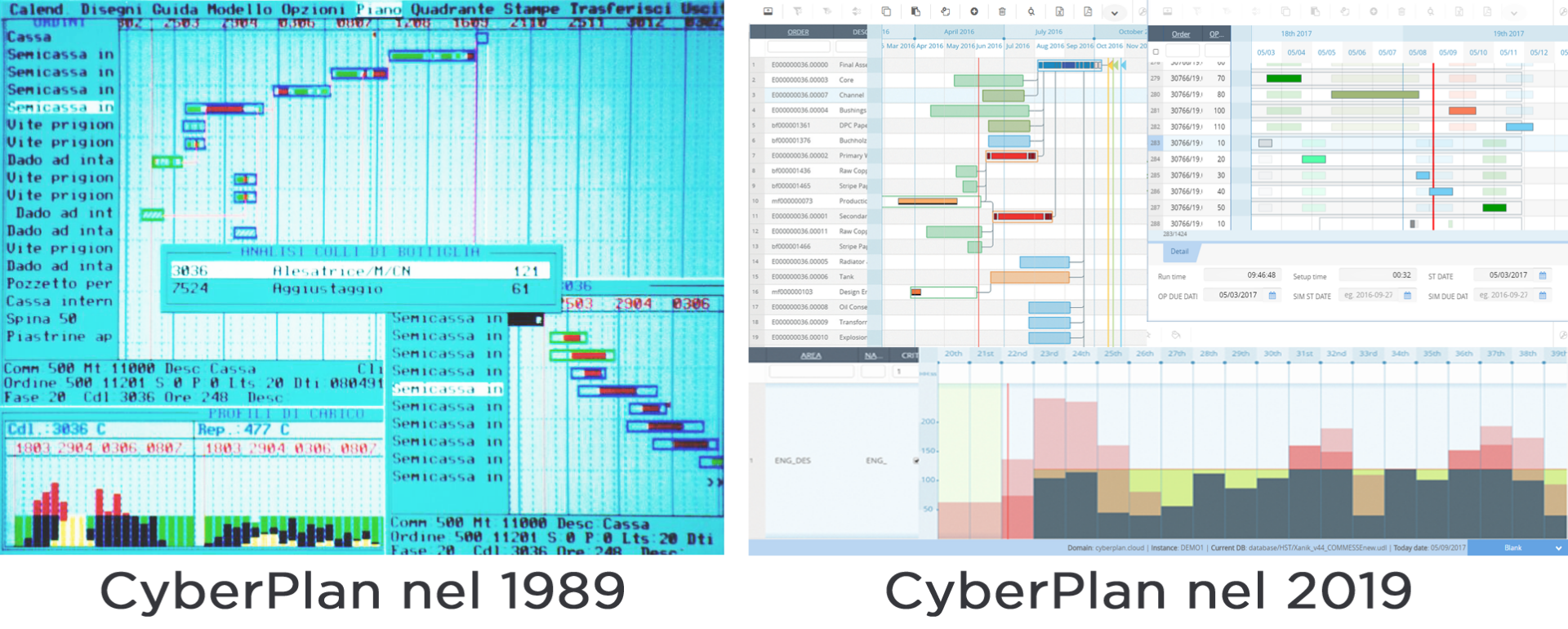

Italian manufacturing is considered among the best in the world and is admired worldwide for its variety and heterogeneity. It is therefore not surprising that APS systems have developed here, well in advance of other countries. The first of these systems is CyberPlan, the APS developed by Cybertec. Founded in the late 1980s as an interactive and intelligent scheduler, CyberPlan was already able, in those years, to simulate the amount of data of an entire company, in a few seconds and offering a high quality result. In the early 1990s, it was equipped with innovative graphics that allowed it to have complete visibility over production and to benefit from the maximum computing power. Cybertec’s APS solution has been continuously evolved and updated, in order to guarantee maximum performance, speed and graphics: hallmarks of CyberPlan. These continue to be the strength for which Cybertec’s APS solution is still appreciated and implemented all over the world. Below are two photos that compare the versions of CyberPlan from 1989 with that of 2019.

Industry 4.0 and advanced systems for the management of production processes

In the era of Industry 4.0, the Internet of Things and Mass Customization, companies find themselves operating in an extremely demanding market with increasingly strong competition. As a result, this environment requires ever-increasing data processing speed, reliability of responses, and responsiveness to unforeseen events. All this while seeking a reduction in costs and warehouses, while maintaining high resource saturation rates and the level of service.

To meet these needs, companies are equipping themselves with APS systems. CyberPlan is the most famous of these systems, thanks to its unique features that allow it to stand out from the others as well as to support the decision-making process, even of the most complex productions.

Ready to learn more about APS software?

If you want to find out what it means to use Advanced Planning and Scheduling software to plan production, contact us and speak to an industry expert who will be available to answer your questions. Click here >