An experienced driver is able to drive a car flawlessly: he knows the road, prevents its course and adapts his driving to the different asphalt and weather conditions. Just like a pilot, Demand Planning conducts and guides planning and scheduling efficiently, adapting production plans to market fluctuations and forecasting future demand to ensure the right sourcing and high-quality customer service.

Whatis Demand Planning

Demand Planning is the basis for the planning of production processes and the optimal management of resources. This process uses predictive analytics to anticipate changes in demand and develop company sales forecasts. Sales data analysis, time series modelling and the use of forecasting algorithms allow reliable demand forecasts to be made based on data available in real time.

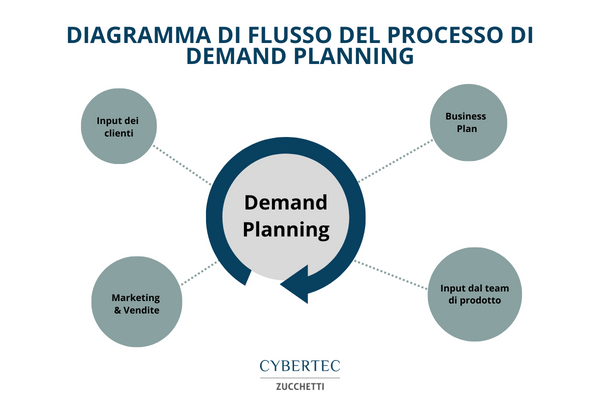

All departments of the company are involved in the Demand Planning process and collaborate in the implementation of forecasts. Predictive analytics provided by Demand Planning software help decision makers balance the short- and long-term needs of the organization, allowing them to manage upcoming market demands and keep sufficient inventory on hand. In fact, forecasts make it possible to define commercial strategies and policies, establish how many products for each SKU to stock and the size of the safety stock.

In addition, Demand Planning can also help manage external aspects, such as suppliers who must deliver raw materials in compliance with the times and rhythms of production processes to avoid any delays. This increases sales, as the company is able to meet demand, and reduces costs related to excess stock-outs.

Characteristics of Demand Planning tools

With the help of Demand Planning software, companies can achieve two important strategic objectives: develop a more accurate demand forecast and have more control over demand modeling. In order to achieve these results, Demand Planning software must have some key features, such as:

- Historical analysis: To provide supply chain executives with accurate forecasts, forecasting processes analyze not only the historical demand for a single product, but also broader macro and microeconomic trends.

- Data collection and analysis: To improve the analysis of past and future demand, the software collects a wide variety of data that is filtered on the basis of different parameters (e.g. product, customer, season and market).

- Ability to shape demand: The software considers information about promotions, planned product launches, upcoming competitor activities, and allows you to accumulate and view detailed plans for future marketing campaigns. In addition, the software is able to predict the expected effects on awareness, demand and revenues that accompany such activities.

- What-if analysis: Having all the information in the system available, the software is able to run scenarios and simulations based on “what-if” factors. The results of these simulations allow potential deviations from planned demand to be predicted and communicated to the necessary areas of the supply chain.

- Communication across the supply chain: Demand Planning software collaborates with other supply chain management systems to review supply through capacity planning. This reduces inventory maintenance costs and excess inventory.

The tools for Demand Planning

At one time companies relied on their knowledge and experience to roughly calculate sales and estimate the quantity of products to be produced accordingly. Then, with the advent of the first computer tools, some companies began to use calculation programs such as Excel to predict sales. Although Excel is still a tool used by many small or medium-sized companies, it is not the best option to professionally manage Demand Planning processes.

Demand Planning software is specifically designed to manage and analyse a large amount of different data, from product demand to market trends, from customer behaviour to external factors. For this reason alone, a Demand Planning solution is preferable to planning with Excel. In fact, Excel is a generic program, which requires a considerable effort to organize, analyze and interpret demand planning data since the data does not update automatically and any changes require time and attention.

In addition, using Excel would give up an essential part of Demand Planning, that is, all those advanced analysis and forecasting features made possible by algorithms and statistical analysis techniques, and consequently the possibility of making more informed decisions based on reliable data.

In addition, a Demand Planning software offers a wide range of integrated features, such as material requirements planning, order management and supply chain optimization, which simplify the planning process and improve the overall efficiency of the company. These integrated tools can help reduce lead times, improve customer satisfaction, and reduce operating costs.

Finally, the use of a Demand Planning software can improve collaboration between departments within the company, allowing you to easily share critical information and data and collaborate on planning and forecasting.

The challenges of Demand Planning tools

Although approaching a Demand Planning software for the first time may be more complicated than Excel, it is not necessarily less intuitive. As with any new tool, even for a Demand Planning software, you must first begin to become familiar with the user interface and the structure of the software, which may also require specific training.

Added to this is the fact that understanding the different forecasting models available in the software and their correct application require specific skills and in-depth knowledge of the business. In addition, data collection and processing can be complex and require the use of other software applications or data collection tools.

Finally, even a Demand Planning software requires continuous monitoring and updating to ensure the accuracy of forecasts and the effective management of planning activities.

Once these difficulties are overcome, the use of Demand Planning software can lead to greater efficiency in demand management and improve the company’s ability to respond to market needs.

Why choose Cybertec Demand Planning tools

To recap, adopting Demand Planning software allows companies to monitor trends that influence future demand, minimizing waste and improving forecast governance to avoid data errors or distortions. In addition, reduced data latency enables real-time demand planning, offering greater flexibility and adaptability to market needs

CyberPlan Demand Planning and S&OP is the software solution that allows demand forecasts to be made, balancing them with real production capacity. Thanks to the simulated environment, it is possible to analyse different scenarios in real time and make effective decisions in line with business objectives, maintaining the right quantity of stock and level of production to maximise customer satisfaction and reduce costs. With CyberPlan Demand Planning and S&OP, you can accurately forecast demand using real data and advanced forecasting models. In addition, it is possible to integrate these forecasts with the actual production capacity of the company.