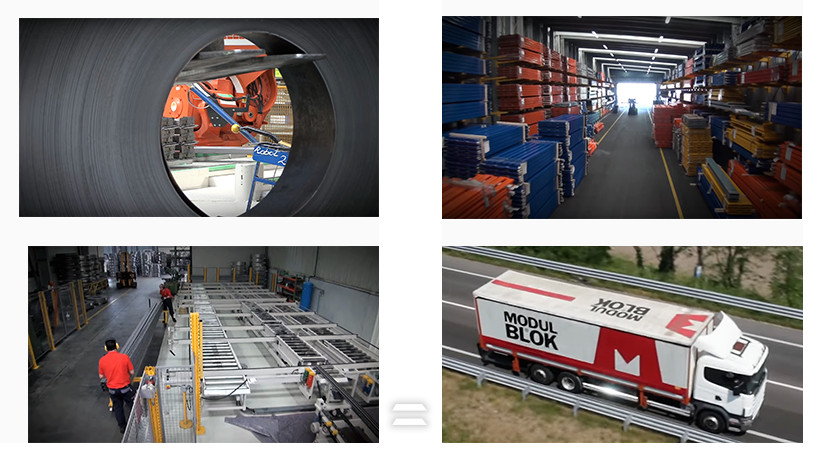

Modulblok, a leader in the production of warehouse storage and logistics systems, has always been focused on guaranteeing the best level of service to its customers. With this objective in 2008, it began an important transformation process that allowed it to give reliable delivery dates, reducing lead time and maximising production efficiency. Andrea Peressi, Production Planning Manager at Modulblok, tells us about the transformation path that has seen numerous improvement projects. Among these, the main ones were the introduction of the principles of Lean production and the implementation of an APS (Advanced Planning and Scheduling) system.

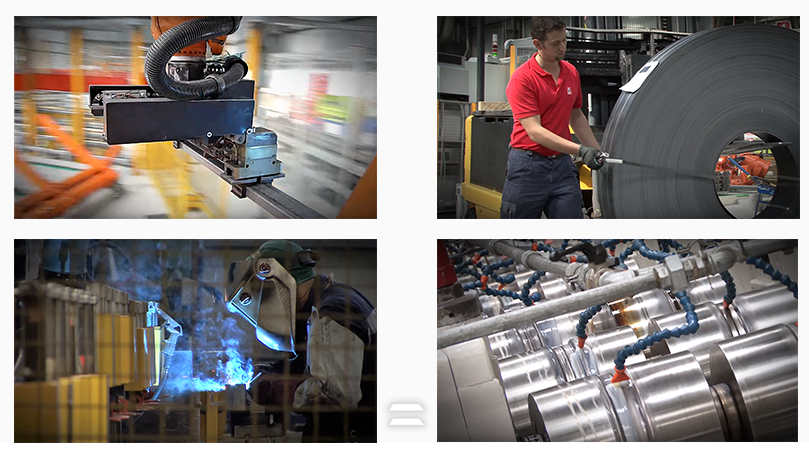

The company, synonymous with performance and innovation

Modulblok is the reference for the production of warehouse storage and logistics systems. In fact, the company’s mission is to obtain organized, high-performance and safe warehouses. To do this, the company respects virtuous principles such as continuous improvement and the search for customised, original and innovative solutions. The company’s priority is to create a new culture, aimed at avoiding waste, pollution and low-value activities, based on the optimization of space, time and costs. Modulblok also operates according to the principles of Lean Thinking to reduce waste to a minimum and improve safety in the workplace, engaging in a virtuous circle of increasing competitiveness.

Make the planning process efficient and streamlined

The need for improvement and transformation has arisen from multiple factors that have thus pushed the company to adopt new processes and solutions. The research and implementation of an APS solution for advanced production planning and scheduling was one of them. The company was equipped with a management system that, however, was not able to support the effective management of a mix between the contract environment and the demand environment and in generating information regarding loads and production orders. The process was therefore manual and production was managed at sight, the times needed to calculate delivery times were too long and no longer sustainable for the level of service desired by the company; the same crossing time was then drastically reduced to increase the company’s competitiveness.

The main objectives expected from the implementation of the new processes and tools were therefore:

- Increase the reliability of delivery dates and the speed of their processing;

- Reduce the time needed to draw up production plans;

- Obtain as much visibility as possible on the production process;

- Facilitate communication between operations and management.

The path from 2008 to the present

The project started in compliance with the best practices of the sector, and therefore from the improvement of the starting data, thanks to the introduction of a data collection system to optimize cycle changes and bill of materials data. From there, the need arose for a tool that was able to give visibility to the loads and certain and rapid confirmation to the sales department about the possible delivery dates.

The first choice made, in terms of APS solution, was unsatisfactory as the chosen tool required too much time to develop a scheduling plan and therefore was not in line with the company objectives.

The determination to find the best solution then led the company to carry out a software selection process that proved to be interesting and engaging and which led to the choice of the CyberPlan solution, thanks to its characteristics and quality. Cybertec’s OPS was thus implemented within a few months.

Over time, the company has grown and with it, some tools and processes have also changed. The use of the CyberPlan software continued uninterruptedly even when the management software was changed. Peressi explains: “Keeping CyberPlan active at a time of delicate transition such as that of the management system has made it possible to avoid the risk of stopping production and has guaranteed the same high level of service to customers.”

Another characteristic of Modulblok is to operate according to the principles of Lean Thinking, which makes it an exceptional case, since the company operates on a contract basis. The shift to operating according to this philosophy has seen the use of the CyberPlan tool as management support in Kanban. In fact, the Kanban cards have been digitized on CyberPlan and the necessary quantities are calculated from the simulations.

A further advance in the use of the tool was the opening of it to roles other than production planning and scheduling. Sharing plans with both management and the purchasing and sales departments has significantly increased intra-company communication and knowledge sharing, while reducing the time it takes to respond to customers.

Results achieved in this path

This virtuous process of transforming production scheduling, together with the installation of CyberPlan, has allowed the achievement of ambitious objectives that can make a difference compared to the competition:

- Achievement of 98% service level;

- 60% reduction in lead times;

- Reduction of the cost of planning by 50%;

- Strong reduction of the missing ones.

Furthermore, Andrea Peressi observes “not only have we halved the cost of planning, but we have standardized the entire process. The standardization of the process together with the intuitiveness of CyberPlan, allows new planners to be perfectly operational in one or two weeks, completely lowering the costs of handovers. ”

Modulblok’s tips for choosing APS software for contract production

The lived experience allows Modulblok to suggest some precautions to be taken when undertaking a software selection to choose an APS:

- Certainly, approaching the process in an organized way and with the right support team guarantees a good success of the project. This is especially true with regard to the data used by the system, which should only be stored in the database of the management software to ensure the uniqueness of the source;

- In addition to this, it is useful to consider the ability of the APS to be easily integrated with other company information systems;

- It should also be considered that the APS is a departmental, that is, a specific and specialized solution, which should not try to remove functionality from the management system, but to enhance it. ERP (or management), on the other hand, has different aims and purposes, therefore it presents different technologies and logics from those of advanced planning and scheduling software;

- Choosing the APS that best suits your needs and with important performance in terms of calculation speed and graphics minimises the necessary resources and increases the benefits deriving from its installation;

- Once the most suitable APS has been chosen, it is essential to configure and model it: the more the APS is “adherent” to the company, the greater the goodness of the plans that this will produce.

Request a CyberPlan Demo

{{cta(‘ab85071a-d654-4295-bbad-b8e8302eeff7’)}}