In the current landscape, where market dynamics are increasingly fast and changing, companies are faced with increasingly complex challenges. One of these is optimal management of business resources and supply and demand planning. In this context, the Sales and Operations Planning (S&OP) process has become a fundamental tool for aligning strategic, operational and production decisions.

In this article, we will explore what S&OP is, how to manage it effectively, and how modern technologies can support companies in making this process robust and efficient.

What is S&OP?

Sales and Operations Planning (S&OP) is an integrated planning process that aims to balance demand with supply, optimizing production capacity and inventories. The main objective is to align business operations with market needs, ensuring that production, procurement and distribution are in line with sales forecasts.

The S&OP process develops through several key phases, including the collection and analysis of sales data, the definition of demand, the planning of production resources, and finally, the approval of operational plans.

Proper management of these phases allows the company to quickly adapt to changes in market conditions, reduce costs and improve customer satisfaction.

How to manage the S&OP process effectively

- Creating a shared vision between departments: The S&OP is a process that involves all company departments, from marketing to production, to logistics. For the process to run smoothly and efficiently, it is critical that all teams share a common vision and work together towards a common goal. Continuous communication between different departments is essential to prevent misalignments and ensure that all business functions are aligned with business priorities.

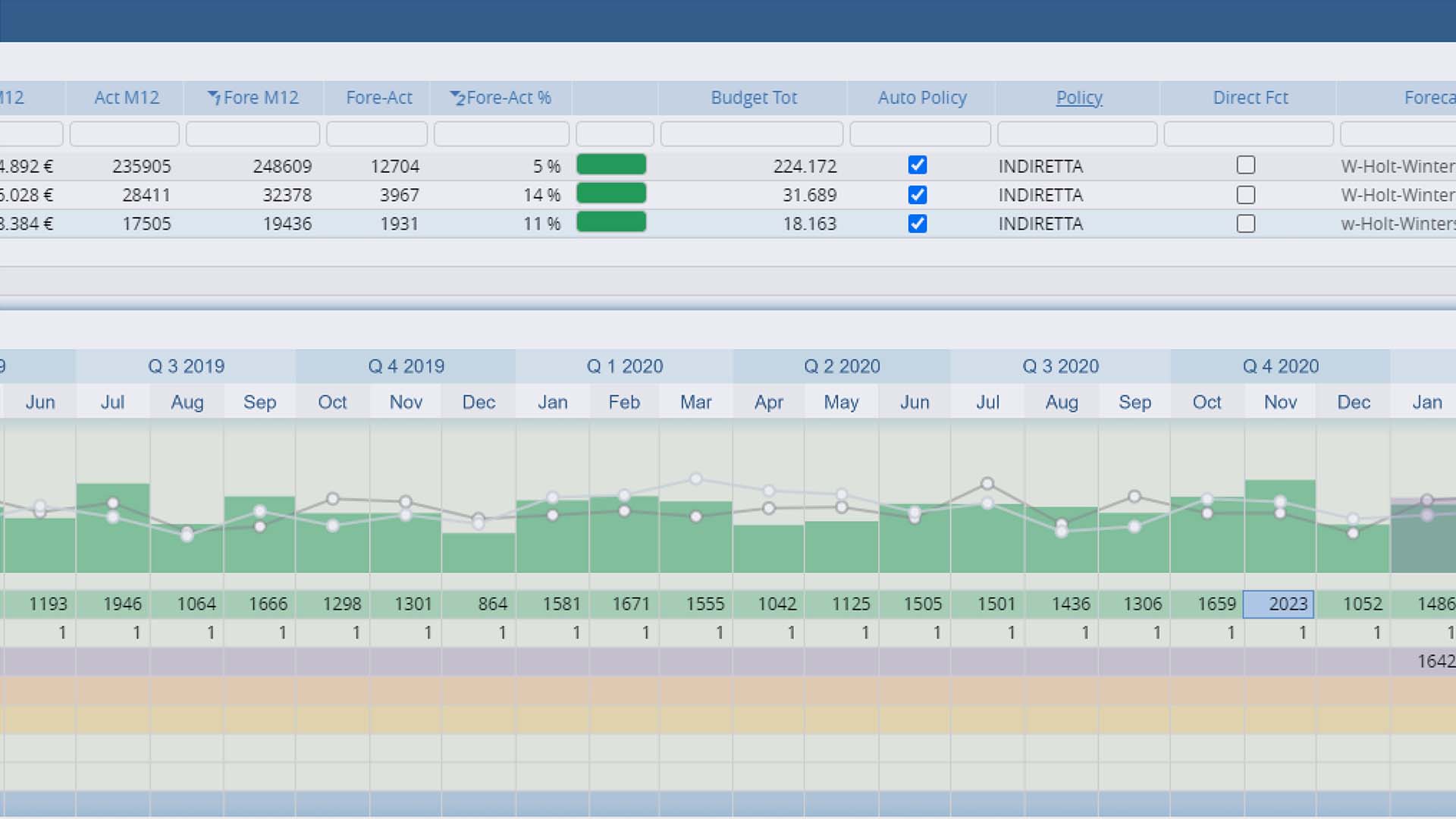

- Predict demand accurately: Another crucial element of the S&OP is demand forecasting. Companies need to be able to anticipate customer demand accurately, taking into account various factors such as market trends, seasonal events, and changes in consumer preference. Accurate forecasts make it possible to optimise production resources, avoiding both excess and shortage of stocks. In this sense, the use of advanced technological solutions, such as integrated planning systems (ERP, APS), helps to collect and analyse data in real time to provide more accurate forecasts.

- Manage supply and optimize production: Once demand is defined, you need to adapt production and distribution to meet it. This involves careful planning of production resources, operational capabilities and delivery times. Flexibility in managing resources and the ability to adapt to sudden changes in demand are crucial to optimising operational costs and reducing lead times.

- Continuous monitoring and review: S&OP is not a static process, but a dynamic one. It is critical to regularly monitor the results of forecasts, compare actual demand with forecast demand, and quickly correct any discrepancies. A periodic review of the S&OP plan allows you to adapt to new information and keep the process in line with business objectives.

- Technology as a strategic support: Automation and advanced data analysis are fundamental tools to improve the efficiency of the S&OP process. The adoption of specific software solutions, such as those provided by CyberPlan, can greatly speed up the entire planning process, reduce errors and guarantee decisions based on real data. Modern S&OP platforms, such as those proposed by CyberPlan, offer tools that integrate information from different business functions, allowing you to generate more accurate plans and respond quickly to unexpected changes, thus increasing business agility.

Read more about how to make the Sales and Operations Planning (S&OP) process, click here to read the full article.

How to avoid the pitfalls of the S&OP process

Although S&OP is a fundamental process for the company, it is easy to fall into some common traps that could compromise the effectiveness of the entire system. Some of the main pitfalls to avoid include:

- Lack of cross-functional collaboration: One of the most common mistakes is failure in collaboration between different departments, leading to divergent visions and inefficiencies in the process. Strong S&OP process governance and effective communication tools can help overcome this hurdle.

- Incorrect or too rigid forecasts: Not adapting to market changes or not updating forecasts in time can lead to wrong decisions. The use of advanced predictive tools is critical to improving forecast accuracy.

- Excessive focus on numbers: Although data is essential, quantitative analysis must be supported by a qualitative approach that takes into account market dynamics and customer needs.

- Poor adaptability: The inability to respond quickly to market fluctuations is a major cause of inefficiency in S&OP. Modern technology solutions, which support agile planning and continuous review, are crucial to maintaining a competitive advantage.

To learn more about the main difficulties of S&OP processes, read the full article here.

CyberPlan: the solution for an effective and sustainable S&OP

Effectively managing the S&OP process is essential to improve business responsiveness and efficiency. A strategic approach and collaborative management, supported by the right technologies, allow companies to respond with agility to market challenges and optimize the resources available.

By adopting an integrated vision, supported by solutions such as those proposed by CyberPlan, companies can not only improve their operational efficiency, but also ensure sustainable growth in the long term. With the right approach, the S&OP process is not only a necessity, but an opportunity to excel in a competitive and ever-changing market.

See CyberPlan in action.

Speed up your Supply Chain. Make the best decisions. Increase performance.

Published on 24/02/2025 by Anna De Lorenzo