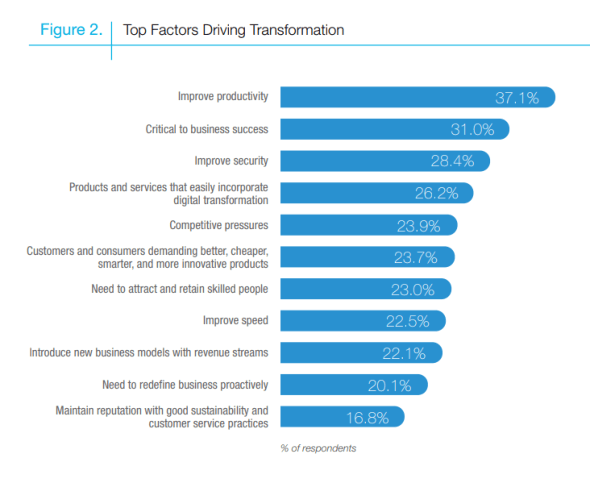

Companies look at digital transformation as an opportunity to differentiate themselves or distance themselves from competitors, increasing their competitive advantage. An IDC survey sponsored by Infor of more than 1,000 executives revealed the main drivers of digital transformation.

With considerable consistency and by a wide margin, the main digital transformation factor with the weight of 37% is productivity improvement.

Why innovate manufacturing companies?

To do this, companies and their managers are looking for innovative solutions and what drives them is the need to increase productivity. This driver of change is largely due to the demand that managers of multinational companies receive and that compete on the world market: to offer and produce more and more using the same, or even less and less, resources.

Alongside the need to increase productivity, what drives companies to embrace digital transformation is the search for solutions that do not reduce or even better increase competitive advantage. It should be noted that many companies have already created and are creating a competitive advantage thanks to business innovation and investments in digital transformation.

What obstacles do digital transformation face in manufacturing companies?

It may come as a surprise, but most of the obstacles that a digital transformation can encounter within a manufacturing company depend on the human element.

Digital solutions, and the benefits they entail, rather than finding an obstacle in the existing IT infrastructure in companies, in fact find some barriers in the existing corporate culture, business model and corporate structure. Among these, the main one seems to be the existing business model. If a company can at first refuse a change of this magnitude, it is also true that underestimating the risk deriving from new incoming companies that, however, expand their share of the market, can become extremely risky if the change in the direction of digital transformation takes place too late. What is happening is that all markets change and therefore companies, to survive, need to change with them. Another barrier is represented by the corporate culture that often also needs change as people who enter and will enter the world of work will bring new skills and attitudes, as well as expectations.

How to increase productivity and strengthen management

Today, however, there are APS solutions, or Advanced Planning and Scheduling Software, capable of giving manufacturing companies potential that would otherwise not be obtainable. This is because the most developed APS allow you to plan and schedule production taking into account constraints and simulating different scenarios before choosing the best production plan, all of which can be shared between colleagues, and in just a few minutes.

Many companies are already reaping the benefits, ranging from increasing the level of service to improving internal communication and better dialogue with suppliers and customers through a reduction in quantities in stock and an increase in productivity and efficiency.

Learn how to increase productivity by boosting your management system

Download the free guide to find out more about the CyberPlan APS solution, the best way to strengthen the production planning department and management (but not only). With CyberPlan, you can guarantee your customers reliable delivery times and an adequate level of service, managing emergencies and unforeseen events with advanced planning and scheduling methods.

{{cta(‘c15e481e-a69f-4941-8c6a-0b4cd5a71b2d’)}}