Production planning is a useful process for manufacturing companies to plan, manage and control the allocation of human resources, raw materials and machinery to achieve maximum efficiency.

Production planning consists of a sequence of steps and allows manufacturers to work smarter in addition to optimizing the production process in the best possible way. This helps manufacturers produce by efficiently managing internal resources to meet customer demand.

Whatis production planning

The fundamental purpose of production planning is to organize the production activity so that it is consistent with the business plans that define the economic-financial objectives of the entire company in the medium term (3-5 years). More precisely, it is a matter of coordinating the production activity, with its own operating logics and efficiency objectives with the sales activity that aims to follow market trends and meet customer demands. While, on the one hand, production to achieve maximum efficiency (minimize production costs) requires production schedules that are as stable as possible over time, on the other hand, lack of coordination can lead to serious consequences: stocks exceeding what is necessary and lack of products in stock when required or poor efficiency in the use of production resources (therefore costs and disservices).

The phases of production planning

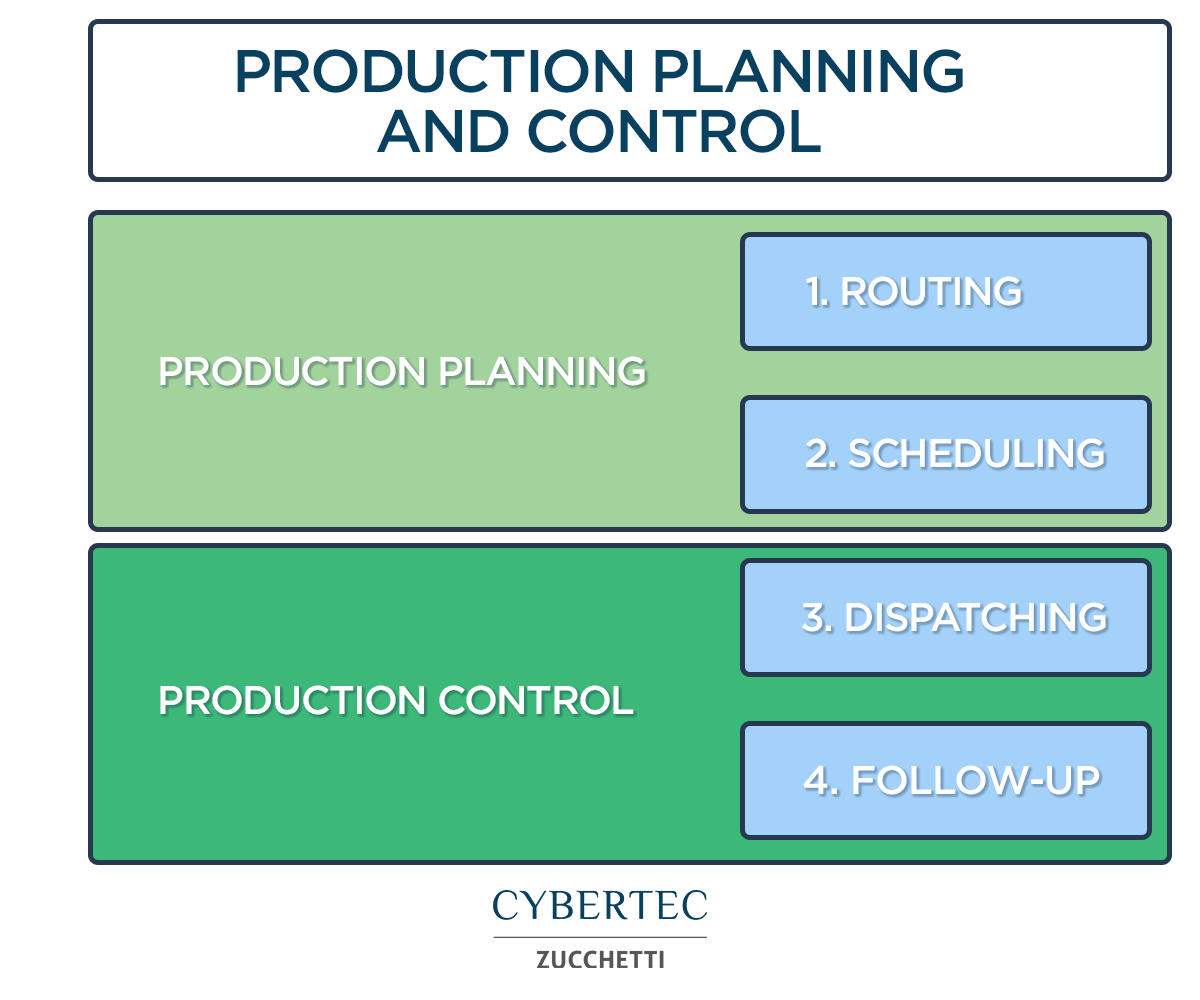

According to the British Standards Institute, there are four essential stages, steps, techniques or elements in the production planning and control process. The four phases or phases of production planning and control are:

- Routing;

- Scheduling;

- Dispatching;

- Follow-up.

The two initial steps, Routing and Scheduling, concern production planning. The last two steps, namely Dispatching and Follow-up, concern production control (or production control).

Routing

Routing is the first phase in production planning and can be defined as the decision process of the production route. In this phase, therefore, the sequence of operations and the path of the products from the raw materials to the finished products stage are decided, as well as the equipment, resources, materials and sequence to be used.

Routing fixes in advance:

- The quantity and quality of the product;

- The people, machines, materials, etc. to be used;

- The type, number and sequence of production operations;

- The place of production.

In short, routing determines “what”, “how much”, “how” and “where” to produce.

Routing can be very simple or complex depending on the nature of the production. If in a continuous production it is very simple, in a job order, it is very complex.

In addition, routing is influenced by the human factor and therefore should recognize human needs, desires and expectations. It is also influenced by the layout of the plant, the characteristics of the equipment, etc.

The main objective of routing is to determine the best sequence of operations in terms of time and cost and ensure that this sequence is followed at the factory.

Routing provides a systematic method to transform raw materials into finished products, leading to regular and efficient work and optimal use of resources (men, machines, materials, etc.). This phase leads to the division of labor, ensures a continuous flow of materials without any backtracking, saves time and space, makes work easy for production engineers and foremen. Routing, therefore, is an important and initial step for the planning and control of production.

Scheduling

Scheduling is the second phase of production planning, followed by routing and means:

- Determine the amount of work to be done;

- Arrange the different production operations in order of priority;

- Fix, for each operation, the start and end date and time.

Scheduling is also performed for materials, parts, machines, etc. and is basically a production schedule.

In programming, particular importance is given to the time element. There are different types of program, such as: Master Schedule, operational program and daily program.

Scheduling serves to use time optimally: it ensures that each process is started and completed at a certain predetermined time, helps to complete the work in a systematic and timely manner and brings time coordination into production planning. All this helps to deliver goods to customers on time, eliminate idle capacity and keep the workforce constantly employed. Therefore, scheduling activities is an important step in production planning and is essential in a factory, where many products are made at the same time.

Dispatching

Dispatching is the third phase of production planning and control. It is the phase of action, implementation or implementation and comes after routing and scheduling. Dispatching means starting the actual production process as it provides the necessary authority to start the work. It is based on route sheets and planning sheets.

Dispatching includes the following:

- Issuance of materials, tools, equipment, etc., necessary for actual production;

- Issuance of orders, instructions, drawings, etc. for the start of the works;

- Maintain a proper record of the start and completion of each job on time;

- Move work from one process to another as scheduled;

- Initiation of the control procedure;

- Recording of machine downtime;

- Dispatching can be centralized or decentralized:

- With centralized dispatching, orders are issued directly by a centralized authority;

- With decentralised dispatching, orders are issued by the department concerned.

Follow-up

Follow-up or Expediting is the last step in the planning and control of production, it has a control function and deals with the evaluation of results.

Follow-up detects and removes defects, delays, limitations, inefficiencies, bottlenecks, loopholes, etc. in the production process. It measures the actual performance and compares it with the expected performance, keeps track of productions, delays and bottlenecks. These recordings are then used to control production. Follow-up is necessary when production decreases even when there are proper routines and schedules. Production can be disrupted due to machinery failures, power shortages, material shortages, strikes, absenteeism, etc.; follow-up eliminates these difficulties and allows regular production to be maintained.

Production planning software

Production planning software is an essential tool for manufacturing companies that want to make a difference in the reference market and be competitive. The benefits that can be obtained range from full control of the production department to the prediction of critical issues up to the drastic improvement of the service level thanks to the lower average lead time. Find out how to improve the performance of your production department by taking its planning to a higher level, contact an expert who will be able to give you the best advice.