Software applications built to determine the best way to plan production are called “decision support tools,” or DSS. Among these, the most advanced are known by the acronym APS, which stands for Advanced Planning and Scheduling, and they are advanced software systems for planning and scheduling.

What are DSS for production planning?

Production managers and planners use APS systems to support the decision-making process regarding the production plan and to predict the completion dates of orders, taking into account the priority given to the latter, as well as the actual availability of machinery and materials.

The result is an optimized production plan, including the allocation of materials to the various orders, the production sequence and information on the use of the various machines. The short response times allow the user to interact with the system and evaluate alternatives to the production plan or study the impacts deriving from variations to the individual parameters of the production plant.

What problems do DSS solve?

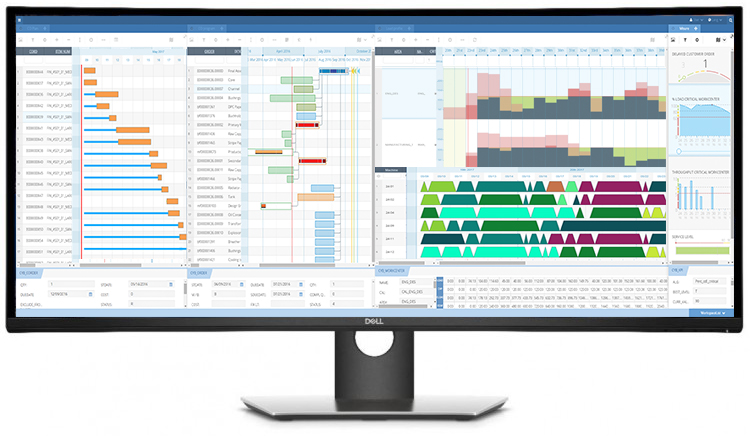

The problem that these systems aim to solve is to determine a schedule capable of enforcing the main objectives. These can be objectives such as fulfilling orders by the target date, reducing total lead time, balancing inventory, or increasing production efficiency. In any case, other main objectives can be decided by the company itself, depending on its priorities. The main purpose of decision support tools, however, is to capture and process data in a way that makes it easily accessible to decision makers. The graphics of these systems is a fundamental point to ensure an adequate reading of these values. The second point, although not by importance, concerns the fact that these tools must allow a strong interaction in order to create future scenarios, as a consequence of the choices made, and evaluate their impacts at a global and not limited level.

How are DSSs made for programming?

The decision support tools for production scheduling are built from algorithms that take into account planning logics and allow very fast processing. These systems must have advanced graphics to allow those who decide to focus on problems and have perfect visibility over the entire production plan without having to search thousands of tables and fields. In addition, they must be able to allow “What-if” simulations to test some possible scenarios, visualize their impacts and then make the best decision. To allow this cycle, the production programming system must do extremely fast processing and thus avoid launching a simulation that takes tens of minutes before having an answer.

The software solution must be able to adapt to the context of the company in question, in order to make it operational and maximize its effectiveness. In this regard, the contribution given by the consultants of the company providing the software is fundamental.

The results are then provided graphically or textually with a Gantt chart or tables, in order to guarantee an immediate understanding and analysis by the planners, who can modify the parameters in real time.

Which one to choose

In order for the aforementioned qualities to be guaranteed, the software must meet certain requirements, which will determine the success of a project.

It is important that the APS is equipped with advanced algorithms, for the management of production programming logics and the simulation of what-if scenarios. The algorithms must be supported by a database in RAM that guarantees speed and interactivity. Dynamic, powerful and clear graphics are essential for understanding, as is configurability for adapting to the customer’s resources. Another fundamental aspect is the integration with the company ERP, with which the APS must dialogue in a harmonious and fluid way for the exchange of data.

Among the APS on the market, a well-known and appreciated solution for decision support capacity is CyberPlan, software developed and distributed by Cybertec.

Are you ready to discover APS to make effective decisions?

Are you looking for a tool to improve the decision-making process of your supply chain or would you like to learn more about how these tools can support you? Talk to an expert to find out more, they will contact you and support you in getting all the information you need.