For companies operating in Industry 4.0, it is increasingly important to implement systems capable of controlling and monitoring production processes in real time.

The MES system plays precisely this role of production control and is a very useful tool for monitoring the production department. But what exactly is it? How does it position itself compared to other business systems? What elements does it consist of?

Whatis a MES system

The acronym MES stands for Manufacturing Execution System and indicates a software that acts as a production control system. Through the acquisition of information on the production cycle, the MES allows you to keep production under control in real time, optimizing all production activities and increasing the operational efficiency of the plants.

Compared to other industrial systems, the MES is located between ERP systems and SCADA systems, therefore between the decision-making level and the production level, which are put in communication by the MES itself to ensure that there is as much consistency as possible between what is planned and what is actually produced.

The elements of the MES system

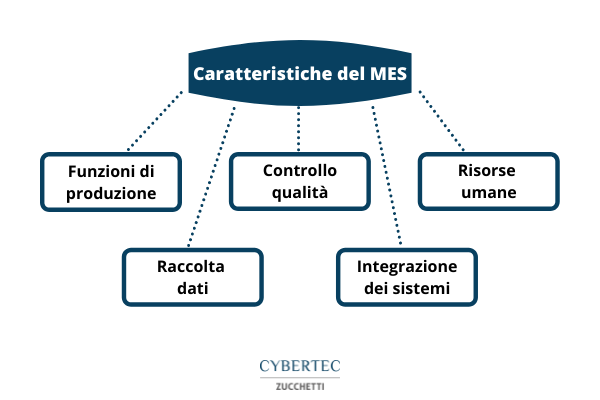

MES software can also vary greatly from one another, but they typically share a number of common features.

Production Functions

They include a series of features related to the various steps and controls during production. First of all, the MES manages all the documentation required by the production department, such as the bill of materials, and any changes and configurations. The system also allows you to trace the parts that make up the products and reconstruct their genealogy, so as to always ensure the correct availability of what you need during production.

Then we move on to managing the execution of the processes, to ensure that the correct workflows are followed. To do this, the MES helps define the process plan, which details the sequencing of production activities, and provides digital work instructions that guide the operator through the various steps. Production progress is monitored, greatly assisting production planners who can thus identify where each unit or batch is located within the production cycle, what materials are needed and when. This level of visibility helps you plan inventory, schedule production, and accurately inform customers when orders are ready. In addition, screenshots and reports help control production and analyze affected areas and events such as the completion of a job are notified via email to the supervisor or support.

In addition to all this, MES systems also include features to manage resources. These include tools such as schedule tables, which allow for a periodic view of the master plan and help maintain regular production. Tools, equipment and other operational resources are also managed to determine which are available, also with a view to preventive maintenance.

Quality management

MES systems allow you to increase the quality of the production process through a series of checks and controls. For example, the Statistical Process Control (SPC) function acquires and processes data to then compare them and keep track of their trends, in order to identify and prevent errors during production. Through the verification of the product configuration, the MES helps to ensure that the products are manufactured according to the correct technical specifications. In the case of poor quality products, non-conformities are managed by reviewing the technical aspects and production conditions. Quality controls also concern incoming goods, equipment and related maintenance, and in general all data acquired from production, such as temperature and humidity.

Human resources

Some features of the MES help manage all personnel involved in operations. The system allows you to record the working time, therefore data relating to entry/exit, absence times and other variables that may affect production. The system also contains all the data related to the certifications and qualifications of employees, so you quickly know if the staff is suitable to perform a certain task. Other functions relate to wage incentives linked to production data; short-term labour planning, with an overview of all active staff to plan for taking into account load levels; and access control, so as to ensure that only authorised staff can access production facilities.

Data collection

As anticipated, the MES helps with the collection and integration of data throughout the production department. In particular:

- Production data: acquired by staff, material consumption and quality, and made available to management in real time.

- Machine data: data relating to the status of the machine, acquired manually through interfaces or automatically through industrial protocols.

- In-process data: collected both manually and automatically through checklists and recorded measurements.

Systems integration

The MES is able to integrate with other production systems, in particular with the company ERP, increasing its potential. At the data storage level, the MES has up-to-date and standardized data and communicates with databases through connectors. In production management, integration facilitates dialogue with machines.

What a MES is for

The MES therefore collects and centralizes data from the surrounding environment, ERP and other company software, filling what are often communication gaps between the decision-making level and the production level. Through this technology, the MES allows you to have complete visibility over the production process and to coordinate it while always maintaining control over its progress.

The real data relating to the entire production cycle and collected in a precise and timely manner allow the process and resource management to be optimised and the machines to be monitored in real time. By analysing the resources used in each activity, cycle times and compliance with planning and costs, you have immediate visibility into performance.

The MES also has the advantage of greatly reducing the possibility of human error, thanks to the considerable reduction of paper and manual activities, replaced by automated data collection and sharing processes.

The sectors where to implement a MES

MES software is successfully used in several industrial sectors, such as consumer packaged goods, food and beverage, pharmaceutical industry, hybrid manufacturing and process manufacturing. This is due to the breadth and variety of the functions it covers.

MES systems contribute to the effective structuring of production processes, planning the division and execution of work and optimally managing resources. They store in an organized way the data acquired and analyzed previously, information that allows to proceed with an accurate quality control and to trace resources and materials in a timely manner.

Among the best Manufacturing Execution Systems on the market is Opera MES by Open Data, a company part of the Zucchetti group, with extensive experience in manufacturing. The company was founded in 1994 by creating the first online information systems for the management and control of the factory and is now an International MES Vendor.

Integrations with the ESM

As seen, the integration of the MES with other business systems is a fundamental step to make a large amount of information available in real time and to fully exploit all the potential that this type of software offers.

Among the various business systems with which the MES integrates there is also APS, the software that deals with the programming and planning of production. The dialogue between the two systems allows you to easily share production information and increase performance.

Among the APS on the market, CyberPlan has the advantage of easily integrating with the main ERPs and other business systems, and works in synergy with the MES system to provide a tool that supports modern and up-to-date management of production capacity. Learn how to implement these tools and increase your production performance.