In recent years, Supply Chain Management has taken on an increasingly important role within production companies, large organized distribution and services. But what does it mean to manage the Supply Chain? With this article you will learn about what pillars it is based on, what benefits it can bring, what the Supply Chain Manager does and what are the most effective tools to manage it.

Whatis Supply Chain Management

Supply Chain Management concerns the management of flows of goods, information and financial resources between companies within the supply chain, with the aim of improving performance and gaining competitiveness.

Initially the term was used with reference to warehouse and inventory management, later the definition was extended to include the concepts of logistics and vertical integration, until it became a management philosophy that aims to create value for the customer.

According to the most recent definition given by the Council of SCM Professionals, Supply Chain Management concerns the planning and management of activities involved in the research, supply, transformation and management of logistics activities. It is based on the collaboration between the partners of the Supply Chain, coordinating the relationships between the various actors of which it is composed.

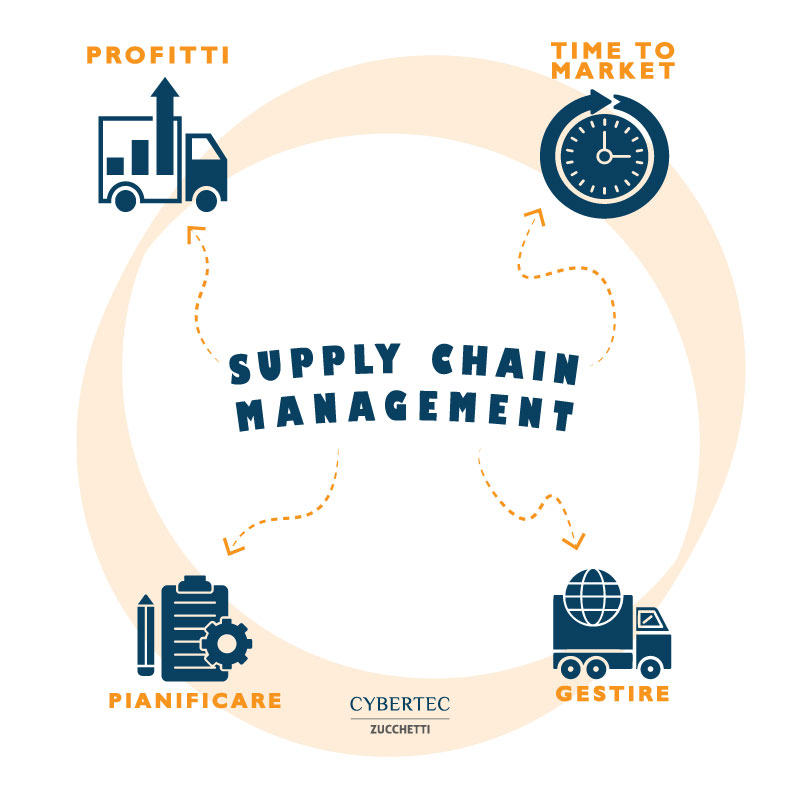

The four pillars of Supply Chain Management

Supply Chain Management is composed of four parts connected to each other in order to guarantee a path as fluid as possible, which results in the implementation of the planned activities.

Integration

Each person involved in the production process communicates and collaborates, leaving a division in watertight compartments. Integrated teams work together to ensure that the product reaches the distribution phase. In this way, all operations can be monitored in their entirety and areas requiring intervention can be easily identified. The best communication allows you to reduce errors, which have a cost in terms of time and money.

Operations

Daily operations are the backbone of the work done by manufacturers. The operational team plays an important role in the supply chain, especially if lean production strategies are used that allow processes to be constantly evaluated to identify possible points where to intervene and act more efficiently. Thanks to these monitoring, managers can ensure the performance of the equipment or can assess whether there is a need to adapt the working hours to the change in production.

Purchasing

Purchases ensure that the company has materials, supplies, tools and equipment, in short everything necessary for the production of products and above all that everything is available on time, always being one step ahead of the process. The right personnel dedicated to purchases is needed for this and not to run the risk of running out of materials, consequently delaying production, or in the opposite case, not to buy in excess by spending the budget badly.

Distribution

The Supply Chain ends when the product arrives on the shelves of a store or, thanks to online commerce, directly in the hands of consumers. The company correctly manages thislast phase of the Supply Chain when the products move quickly from the warehouse to the customer.

The benefits of Supply Chain Management

Effective supply chain management, based on real-time data and a global view of the entire chain, can contribute to different types of benefits in the company. The main ones concern an improvement in performance in the operational phases and a decrease in costs that has an impact on profits with a positive domino effect.

Better collaboration thanks to an automated flow of information throughout the Supply Chain. This is a challenge for many companies, which often miss out on sales opportunities due to fragmented information.

Better quality control through greater control not only over its own direct suppliers, but also over suppliers of suppliers. To do this, it is possible to set minimum quality standards that secondary suppliers must comply with. Other options include the introduction of process guidelines that allow suppliers to align with quality requirements, or periodic audits and analysis of relevant KPIs to analyse supplier performance and compliance.

Greater efficiency thanks to real-time data on the availability of raw materials and production delays. With this data, companies can create backup plans to reduce risk and avoid further problems such as out-of-stock stocks or delays in deliveries to end consumers, avoiding negative impacts and working more streamlined, without interruptions in the supply chain.

Keeping up with the demand, predicting it more correctly with access to real-time, accurate and integrated data allows. There is also greater visibility on changes in market conditions, avoiding the bullwhip effect, an amplification of demand that has negative consequences on the entire Supply Chain precisely due to delays in communicating changes in demand and stocks.

Optimising shipments by finding the most suitable solution to deliver orders quickly while minimising costs, depending on whether you have to ship small packages or large volumes. What is saved in this way can help increase profits, but it can also be reinvested in consumers to improve their satisfaction.

Reduction of overhead costs, in particular those related to the accumulation of slowly rotating stocks, replacing them with those at higher speeds and which produce profits. Additional warehouse-related costs, which affect overhead, can be reduced by optimizing the layout, using some automation solutions, and implementing a better inventory management system.

The role of the Supply Chain Manager

The Supply Chain Manager plays a crucial role in the effective and competitive performance of their company. Operating within the production, sales and distribution sectors, it deals with procurement, purchasing and sales, supervising all production in its phases.

For example, it defines the characteristics of the products to be purchased and negotiates the budget to be dedicated to procurement. It also has a very important role with suppliers, in fact it researches them and interacts with them for commercial negotiations. From an operational point of view, it plans purchases and monitors sales trends, intervening on prices or the supply plan if necessary.

The right tools and the right software help the Supply Chain Manager in his daily operations and achieve the desired results, such as increasing the level of customer service – measured by on-time delivery -, greater productivity and reducing Work in Process (WIP) and warehouse costs.

The Future of Supply Chain Management

The Supply Chain of the future will be driven by processes already underway today, such as the centrality of the Customer Experience and the increasingly advanced technologies put in place.

The Supply Chain will have to be flexible and responsive to adapt to the greater needs of customers and will develop in a network made of nodes, and no longer in a linear model, where the use of technology will guarantee transparency and visibility. Precisely because of the greater complexity in which it is divided, which reflects the greater purchasing options of customers, the Supply Chain will have to be agile to adapt better. Also for this reason, its planning will take place on an ongoing basis, allowing greater alignment between production and execution and greater precision.

Meeting customers’ expectations quickly and on time means taking the right steps towards their loyalty, and Supply Chain Management will increasingly contribute to this task, while also maintaining a focus on increasing efficiency and reducing costs.

Supply Chain Management Software

So what are the software that companies can use to better manage their Supply Chain? Although there is now a lot of talk about industry 4.0, digitized factory and the Supply Chain itself is going through transformations with an increasingly technological footprint, very often many companies plan their production still relying on Excel, underestimating the risks that this entails.

Relying on Excel to make important decisions on planning and scheduling, decisions that have direct consequences on performance, means relying on dozens and dozens of spreadsheets, which often require very laborious processing on the cells even in the case of minor changes. When spreadsheets are many, it becomes difficult to search for the information within them, share the data between different departments or simply be able to have a general picture to be able to make accurate predictions.

For these reasons, today’s Supply Chain needs the right tools and it is advisable to use planning software that allows you to centralize data and make it accessible and usable by users who need it, wherever they are. Using these tools means making your company more responsive and achieving your goals faster, saving you time.

A positive example in this regard is that of the so-called tigers of the Northeast, the 100 companies based in the provinces of Veneto and Friuli Venezia Giulia that between 2012 and 2016 had the best performance in terms of margins and income. A common denominator of the successful companies that have distinguished themselves is a strong specialisation. But 60% of the top twenty manufacturing companies also use CyberPlan, advanced production planning and scheduling software. APS CyberPlan allows you to schedule production effectively and efficiently, obtaining results such as increased productivity and greater alignment between production and objectives, with a higher level of service. Essentially, it is a tool that puts the Supply Chain Manager in a position to do their job to the best of their ability and to make the company more competitive.

The success stories concern many other companies in the most diverse sectors. You can learn more about the results obtained by Supply Chain Managers who use these tools daily with dedicated case studies, which show how companies in the automotive, food, packaging or plant engineering sectors have managed to improve their performance through the use of CyberPlan.