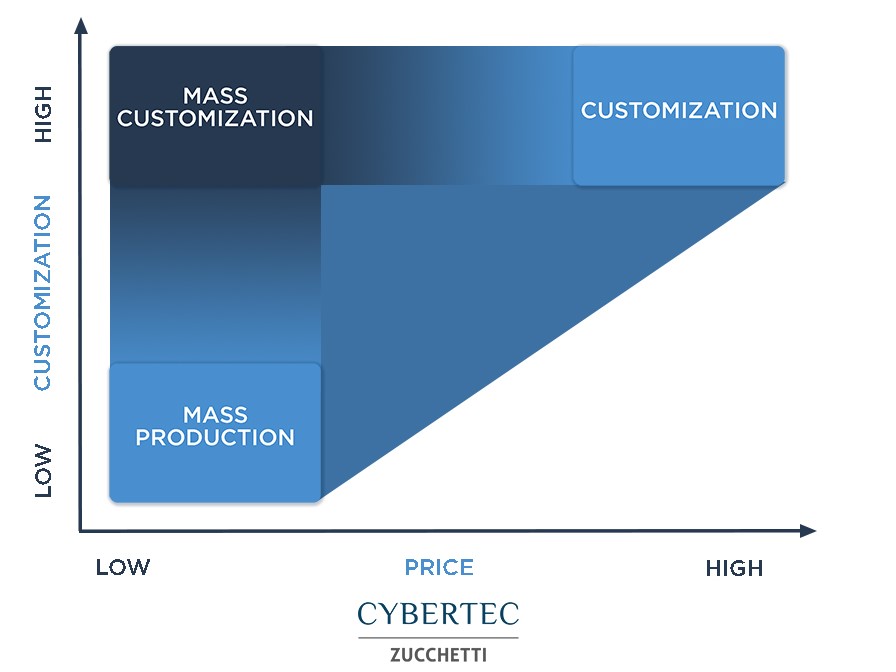

Factory 4.0 and additive manufacturing lead companies towards a minimisation of warehouses and a “mass customisation” of products. All this can lead to a radical change in the management of warehouses by companies and in the transport systems used by them. A further important impact also occurs on information systems, which must support the flow of materials in parallel.

Investments in production plants: is that enough?

Today it is thought to seize the opportunity of mass customisation mainly through investments in production technologies and automation of production plants. Bringing mass production, with its critical issues, to levels of customization equal to those of the ETO, ATO and MTO means increasing the amount and type of difficulties for manufacturing companies. Industrial companies thus modified ran the risk of not being able to guarantee the desired solutions and having to support at the same time an increase in the complexity of production, inventory levels, costs, investments and a decrease in the level of service. An undesirable framework that risks putting companies in difficulty.

Production processes can hardly continue to be managed with tools and methodologies devised in the 1970s such as ERPs flanked by countless Excel sheets. This is an extremely dangerous situation since the existing difficulties faced on a daily basis could one day be added to further ones, typical of other strategies, and therefore more risky.

The suggestion of Helmut Kirchner, supply chain expert and creator of CyberPlan

“Our suggestion, which derives from the successful experiences gained with companies operating with MTO and ATO systems, to avoid these difficulties, is to carefully evaluate investments in production capacity by balancing them with adequate supply chain management and control technology,” says engineer Helmut Kirchner, founder of Cybertec and creator of the CyberPlan APS.

The CEO goes on to say that “Goal is therefore a balanced investment that also makes it possible to improve the control and management of production by taking advantage of opportunities in a profitable way thanks to today’s APS (Advanced Planning Systems), appropriate and very advanced governance tools capable of calculating at finite capacity”.

APS solutions also boast the ability to support lean methodology and philosophy, even under variable mix conditions, optimising warehouse management. The needs of leading companies have motivated us in recent years to invest in the direction of bringing the mechanisms and results of lean manufacturing also in thisarea of productions characterized by high variability, because they are customized.

CyberPlan: Advanced Planning and Scheduling Software (APS)

Cybertec solutions allow information systems to provide the company with the technical capacity to coordinate production so as not to incur problems and delays but rather to reduce inventory levels, complexity and costs.

In this way, the company increases the level of service and seizes thisexcellent opportunity, preventing it from becoming a nightmare for production.

What we believe in and what we try to do is to help companies obtain this capacity thanks to our tools so that they can reach that desired level quickly and efficiently.

Learn more about Cybertec solutions >

Allow the production planning department to work effectively and efficiently thanks to software solutions such as CyberPlan that allow planners to focus on high-value activities, delegating repetitive calculation competitions to the APS. Contact a Supply Chain expert and find out how to upgrade your production department.