Plastopiave, active in the production of containers for any use, has managed the considerable dimensional and production growth thanks to foresight and innovation. These two qualities have led the company to innovate the systems and characterize this change with the addition of software for advanced CyberPlan planning and scheduling. The head of the Plastopiave plant, Rudy Franceschin, told us about the experience of the Venetian company.

What prompted you to look for an APS?

Plastopiave has always pushed in the direction of innovation and increased performance, investing in new plants and new IT infrastructures that support the former and allow you to derive maximum benefit from them. Regarding production planning, before the installation of CyberPlan advanced planning and scheduling software we used the GrafComm tool. However, this software was too slow and still required the support of paper documents and therefore did not meet the needs of planning. We therefore decided to look for a more advanced and faster solution, which would allow us to manage the production and resources available in the best possible way. The software selection made allowed us to notice the differences between the different APS and highlighted the goodness of the CyberPlan solution.

How did the implementation of the CyberPlan APS take place?

Following the choice of the CyberPlan solution, we worked as a team together with Cybertec consultants for the analysis and definition of the project, which allowed us to obtain the maximum benefit from the tool. This part of the analysis should not be underestimated: it is essential to be able to make the best use of the APS tool in one’s own reality and to minimize subsequent manual activity. The assistance received by Cybertec’s consultants was then of the firstorder, they are extremely capable, available and serious people, three fundamental qualities in these situations.

What are the characteristics of Plastopiave production?

Our product portfolio includes over 8,000 items, each available in different colours, in addition to which the sector has increasingly shifted towards just-in-time production, so that the entire supply chain has now moved in the direction of production on order. CyberPlan has been fundamental in this step, since it allows us to better manage orders by guaranteeing short and certain delivery times to customers.

Does CyberPlan also help you communicate better?

Absolutely. It may not be the first thing you think about when it comes to APS, but CyberPlan helps communication both inside and outside the company. If we look inside Plastopiave, in fact, our salespeople today can see the progress and the date of fulfillment of a customer’s order in full autonomy and without requesting information from their planning colleagues. This avoids potential communication issues and allows both roles to spend more time on high-value tasks. CyberPlan also allows us to communicate more effectively with the owner or other managerial roles, thanks to the use of filters and the easy and quick export of tables.

CyberPlan also helps communication outside the company: our customers are many and each with their own needs, being equipped with CyberPlan allows us to continuously monitor customer orders, in case of any need or variation.

What aspects do you find most useful about the CyberPlan APS?

In addition to the aforementioned calculation speed and security in guaranteeing certain delivery times, CyberPlan allows us to have visibility on all existing orders every day, at 360 degrees. To this I would add the simulation capacity of CyberPlan, which allows you to evaluate the consequences of any changes to the existing plan, and speed, which allows you to see the results of these simulations in a few seconds, for example. Another positive thing about CyberPlan is the possibility of having “views” that allow you to analyze useful content for different reasons, these can then be customized according to your needs.

Plastopiave

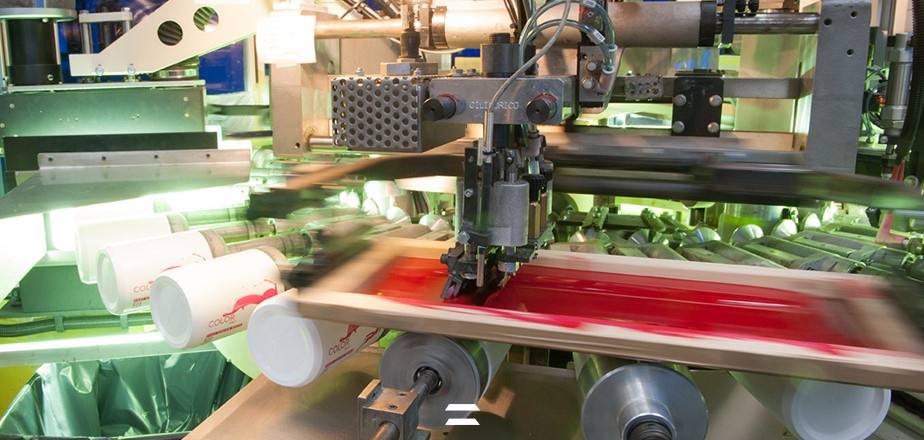

Founded in 1961 on the initiative of Francesco Giacomini, and today carried out by his sons Attilio and Michela with over 200 collaborators, Plastopiave manufactures plastic containers, screen printing and labelling, offering a 360° service for the food, cosmetic, pharmaceutical and other sectors. The company produces the more than 1000 products in the range using the different polymers within the more than 20,000 square meters dedicated to the production of more than 35,000 in total, and using a cogenerator and a large photovoltaic system.

Request a CyberPlan Demo

Host a CyberPlan Demo to see for yourself how it can support your business.