Stefano Tironi, IT Manager of Lonati Spa, tells about the experience of the leading company in the production of circular machines for hosiery, in the implementation and use of the APS CyberPlan solution. The Brescia-based company has chosen with foresight to plan its production in a modern and advanced way, pursuing the company’s objectives of improvement and efficiency.

How did the search and selection of an APS software take place?

“Fortunately, we have CyberPlan that has been replacing a not-so-advanced and fast MRP for over 15 years. In fact, the MRP solution we had required many, many hours to carry out the calculations and processing so much so that there was a risk that in the morning a machine would not be usable due to the MRP that had not yet finished the calculations carried out throughout the night.

Driven by the desire to change the existing situation, we set out to find a solution that was quick, certain in results and autonomous, that is, detached from any platform but at the same time suitable for any ERP. We then made a careful software selection that led us to choose the CyberPlan solution.”

Why were you looking for a standalone APS but suitable for any ERP?

“We were in the process of changing the ERP management software, so we wanted to be able to choose the best solution both in terms of ERP and APS and at the same time be sure that there were no constraints in terms of integrations and dialogue between the systems in the company.”

How do you use CyberPlan?

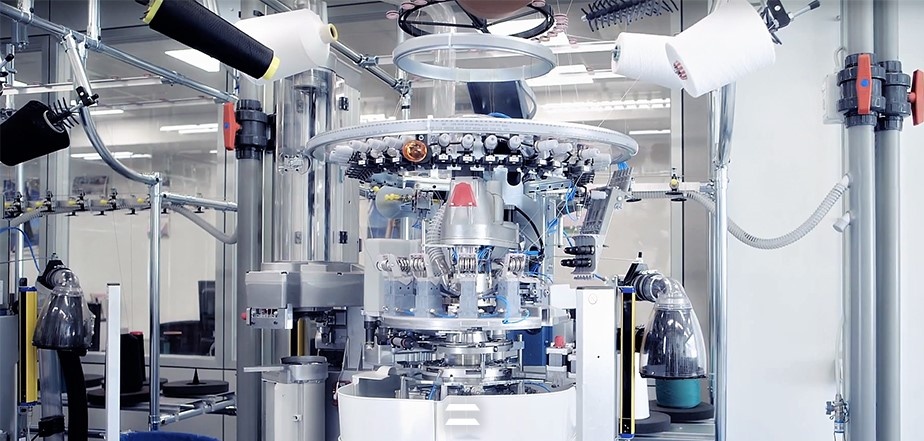

“CyberPlan allows us to plan the production of more than 50 models of circular machines for factories and to do it at full capacity. To do this, check that the materials necessary to satisfy orders are available in the warehouse. It then tells us what we need to order, what we need to move, or cancel, etc. The results of CyberPlan are fundamental for production, so much so that every morning users view the results to see how we are positioned and what actions need to be taken.

CyberPlan then allows us to comply with the requests of the sales department, satisfying customer requests and avoiding penalties.

It is a product that we trust so much that its results are sent directly to the purchasing department so that we can proceed with production without any problems whatsoever.”

What aspects do you like most about CyberPlan?

“One of the qualities I appreciate most about CyberPlan is the speed of computation. The speed is such that in case of urgency and need it is possible to run the MRP even during the day. All this in total peace of mind and without having to stop machines.

Another valuable aspect of CyberPlan is its reliability: it is so reliable and natural to use that you do not realize you are using an Advanced Planning and Scheduling tool. We never need to contact support even though you use it daily.

What is fundamental, however, is the fact that it fully performs the main task, that of production planning. CyberPlan, thanks to its rapid processing, leads us every day to a perfect plan, or almost.”

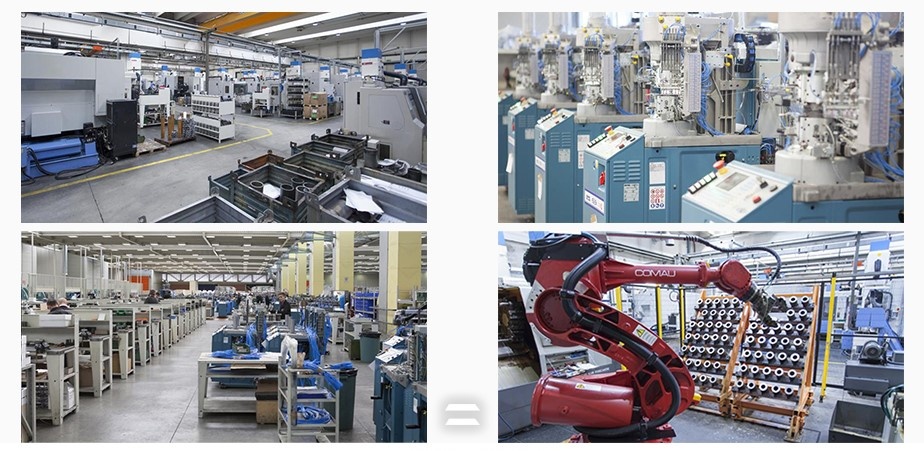

Lonati spa

For over 70 years, Lonati Spa has been committed to a constant search for innovative products, technologies and materials to offer its customers around the world the best that textile machine technology can offer. The Brescia-based company produces textile machines for footwear factories characterised by high quality and competitive prices, a compendium of mechanical-textile and electronic possibilities. The company is located on an area of 80,000 square metres, of which 24,500 are covered, in Brescia. The production capacity of Lonati is about 11,000 machines, among the more than 50 models in the portfolio. The penetration of the international market covers 60% of the machines produced and the sale takes place all over the world. Customer service is top-notch in all the more than 60 countries served, in line with the company’s philosophy of maximum internal product quality and identical quality in external relations with its numerous customers. Lonati is therefore a solid reality of the Brescia economy at national, European and world level.