The enormous amount of data concerning the supply chain that companies have today, pushes them to look for analytical solutions that allow them to decipher it, drawing useful data to improve decision-making.

Companies that are trying to optimize their S&OP efforts need capabilities that allow them to analyze historical data to predict what could happen in the future, this is a great opportunity that allows companies to become an organization that bases its decisions on data. Benefits include high ROI, operating cost decreases, revenue increases, and customer service and product mix improvements.

Finding the best solution can be a time-consuming and energy-intensive task. Fortunately, however, these analysis options can be classified into three distinct types, none of which is better than the other, but rather coexist and complement each other. Having a holistic view of the market and the company’s positioning within that market requires a robust analytical environment that includes:

- Descriptive analysis, which uses data aggregation and data mining to provide insight into the past and answer the question: “What happened?”;

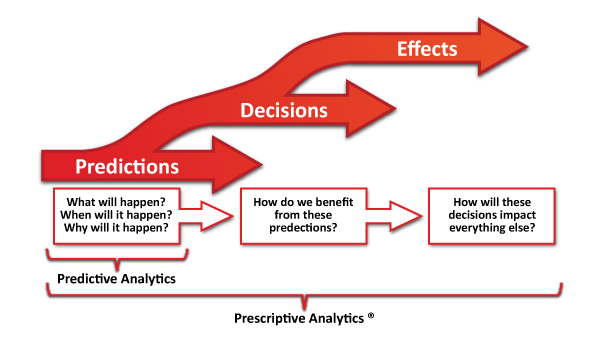

- Predictive analytics, which uses statistical models and forecasts to understand the future and answer the question: “What could happen?”;

- Prescriptive analytics, which uses optimization and simulation algorithms to indicate possible outcomes and answer the question, “What should we do?”

Descriptive Analysis – Analyzing the Past

Descriptive analyses or statistics do exactly what the name says, that is, they describe, summarizing them, the raw data of the supply chain transforming them into human-interpretable analyses. They are analyses that describe the past. Descriptive analysis is useful because it allows us to learn from past behaviors and understand how these might affect future outcomes.

The vast majority of the statistics we use on a daily basis fall into this category. Descriptive statistics are useful for showing things like quantities in stock, factory efficiency, service level (percentage of On Time Delivery on past orders).

Predictive Analytics – Forecasting the Future

Predictive analytics is rooted in the ability to predict what might happen. These analyses are about understanding the future, providing companies with in-depth, data-driven insights. In fact, predictive analysis provides estimates of the probability of a future event or result occurring. It is important to remember that no statistical algorithm can “predict” the future with certainty as predictive analysis is based on probabilities. Companies use these statistics to predict what might happen in the future.

What these statistics try to do is take the available data and fill in the missing data with the best guesses. To do this, they combine historical data found in ERP, CRM, HR and POS systems in order to identify any patterns in the data and apply statistical models and algorithms in order to capture the relationships between the various data sets.

A practical twist known to most people is the use of predictive analytics to produce a creditworthiness score. In manufacturing, this type of analysis is carried out for sales forecasting, forecasts about purchases, forecasts about inventory levels from a myriad of variables and so on.

Prescriptive Analysis – Tips on Possible Outcomes

The field of prescriptive analytics is relatively recent and allows users to “prescribe” a range of possible actions and guide them towards the best solution. In short, these are analysis tools whose purpose is to provide advice. Prescriptive analyses attempt to quantify what the outcomes of decisions would be before these decisions are actually made, so as to provide decision support. In addition, the most refined prescriptive analyses, in addition to predicting what will happen, also predict the causes and provide indications about the consequences that will arise, on various aspects.

Prescriptive analyses go beyond descriptive and predictive analyses by recommending one or more possible courses of action. They essentially predict a greater number of future scenarios and allow companies to evaluate a greater number of future outcomes that might occur based on their actions. Prescriptive analysis uses a combination of techniques and tools, such as: business rules, algorithms, machine learning, and computational modeling procedures. These techniques are applied based on input from many different data sets, including historical and transactional data, real-time data feeds, and big data.

Prescriptive analytics are relatively complex to govern but are used daily by the most ambitious companies. If implemented correctly, these analytics can have a big impact on business decision making and profits.

Make effective decisions for your supply chain with prescriptive analytics

For a manufacturing company, the ability to carry out prescriptive analyses is increasingly a competitive advantage. Such a complex analysis requires advanced tools both from a performance point of view and from a technological point of view. In this sense, the most used and recommended tool by Italian manufacturing companies is CyberPlan, Cybertec’s Advanced Planning & Scheduling. In fact, this tool allows manufacturing companies to carry out descriptive, predictive and, above all, prescriptive analyses with very high speed, precision and ease of interpretation and use. The results obtained by the companies that use it are tangible, substantial and have a strong impact on the company’s economic results, especially in terms of reducing costs, increasing productivity and improving the level of service.

The Benefits of Supply Chain Analysis

The analytics function corresponds to the ability to make decisions based on a summary of relevant, up-to-date and reliable data. In many cases, this data is then represented in an effective and easier to read way thanks to graphs and other means. Usually Supply Chains produce huge amounts of data, more or less voluntarily. Supply Chain Analytics helps to interpret all this data, making use of it, discovering correlations and generating insights, and can also help a company make smarter, faster and more effective decisions. Benefits include the ability to:

- Achieve a significant Return On Investment (or ROI). According to a Gartner survey, 29% of the companies surveyed achieved high ROI using analytics, while only 4% did not get any return.

- Predict possible risks. Supply Chain analytics helps identify potentially dangerous situations and helps predict future risks by identifying patterns and trends throughout the Supply Chain.

- Increase planning accuracy. By analyzing customer data, supply chain analysis can support a company in forecasting future demand. It helps a company to decide which products should be reduced in production or to understand what needs the customer will have after the initial order.

- Achieve a leaner supply chain. Companies can use supply chain analytics to monitor warehouse, partner responses, and customer needs to make more informed decisions.

- Prepare for the future. Advanced analytics for supply chain management can process both structured and unstructured data, giving companies the ability to receive timely alerts to make optimal decisions. This type of analysis can also create correlations and patterns between different sources to provide alerts to reduce risks, at a low cost and with a lower impact on sustainability.

Thanks to Supply Chain Analysis, companies therefore have production intelligence, can become more efficient and avoid interruptions, while supporting new business models.

To learn more:

To learn more about CyberPlan and how to increase the performance of your supply chain download the free supply chain guide or contact Cybertec and book an appointment with an expert who will answer your questions.