It is easy to waste resources when they are unlimited, but unfortunately the world has realized that the Earth cannot sustain a constant consumption of resources. Sustainability initiatives are the order of the day and humanity is stepping up its efforts to reduce its impact on the planet. For years consumerism (especially personal electronics) has been a huge part of the sustainability problem, flooding landfills with harmful waste.

These are some of the reasons why supply chains are now using a new approach: instead of focusing only on the life cycle of a product until it is delivered into the hands of the consumer, many are working to create a “closed-loop” supply chain and Supply Chain Planning that maximizes the value of resources by producing less waste. Let’s take a look at what that entails.

Whatis the Closed Loop in the Supply Chain

Closed Loop Supply Chain Management (abbreviated CLSCM) means the design, control and management of a production system to maximize the creation of value throughout the entire life cycle of the product with the recovery of value from different types and volumes of yield over time. (V. D. R. J. Guide, Harrison, & Wassenhove, 2003).

A closed-loop supply chain essentially combines a traditional supply chain (forward logistics) with reverse logistics that considers the item in the period after it has fulfilled its original purpose. After the item has been produced and distributed, the manufacturer works to ensure that the item is returned, once it is no longer functional or necessary. Reverse logistics then comes into play, the purpose of which is to recover the items so that they can be repaired and resold or broken down for reuse in future products. The term “closed loop” refers to the fact that the chain is intended to maintain and recover value from unused products, while helping to create as little waste as possible.

How the Closed Loop works

Closed-loop supply chains can make a substantial contribution to reducing waste.

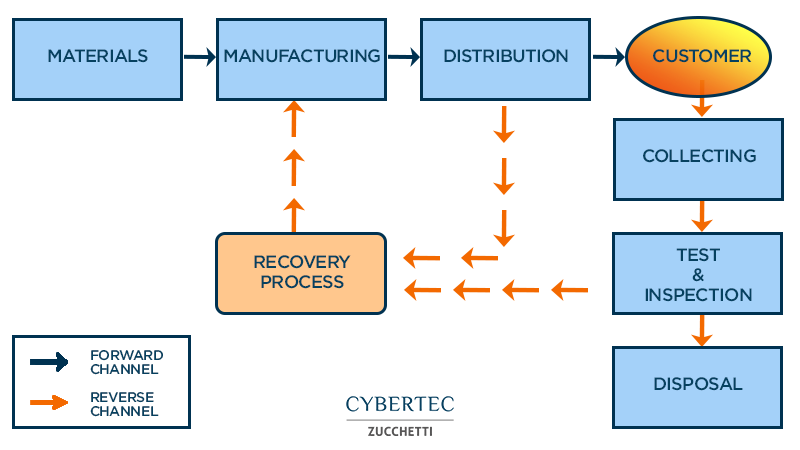

Most products require the use of raw materials for its production, but in some cases recycled materials can also be used. Even if raw materials are used, the goal of the closed-loop supply chain is to reduce the number of raw materials needed, through the recovery and reuse of post-consumer materials.

The original product, once made, is sent along the supply chain as usual, going to a distributor and retailer, finally reaching the customer. This is where reverse logistics come into play whereby the product must be recyclable or there must be take-back programmes that allow the supply chain to be ‘shut down’.

In this case, customers who discover that their product is not working properly, or simply does not meet their needs, return the items. The manufacturer must then determine if the item can be repaired and resold or if it needs to move to another phase of the reverse logistics path. In that case, the item could be recycled, along with products that other consumers send to the manufacturer through take-back programs. These programs allow customers to recycle potentially hazardous items such as electronics, whether they are broken or obsolete, so that they can be disposed of and recycled according to environmentally friendly processes. Once these products have been recycled, they can be found in new products.

The benefits of the Closed Loop approach

The Closed Loop approach is increasingly relevant, especially in sectors such as consumer electronics; this is due to the fact that landfills around the world have been filled with plastic, heavy metals and other non-biodegradable materials. In addition to being a threat to public health and safety, especially in the countries where they are dumped, these wastes can be a valuable source of materials for the creation of new products. By recycling some of these materials, we reduce the impact on our planet in two ways: by reducing items destined for landfill and by reducing the impact of extracting new natural resources for production.

In addition, companies benefit from the money savings obtained by reselling products that may not need more than a small repair, they can save by using recycled materials that can be cheaper than raw materials and finally obtain clear benefits in terms of image and reputation towards internal and external stakeholders. Finally, when a sustainable initiative saves the company money, it is a win-win situation, and a Supply Chain Closed Loop can do just that, if managed correctly.

The Closed Loop approach in Software

If we talk about Closed Loop System instead, we are referring to something quitedifferent. Systems of this type, in fact, are designed to achieve and maintain the desired conditions thanks to a continuous process of control and comparison with current conditions. If a difference is perceived between the current situation and the desired one, this signal is used to change the system settings and allow the goal to be achieved. In this sense, the output is used as input for the continuous correction system. The CyberPlan solution uses a Closed Loop approach to allow the company to achieve the ideal production plan in light of the current situation thanks to an extremely fast planning and scheduling system that dialogues with the management software by exchanging updated and accurate information at high speed.

Plan production quickly and accurately

Fewer and fewer manufacturing companies are taking continuous risks about their future results by deciding to plan and schedule their production with spreadsheets created by operators and not shareable. Nowadays, in fact, the world of manufacturing has advanced and specific software solutions, evolved over the years and completely dedicated to supply chains. The CyberPlan solution brings with it the fruit of thirty years of experience aimed at supporting Italian manufacturing companies. Find out how to use this solution and quickly get great benefits by contacting an expert at your disposal.