Gortani’s project started from needs such as increasing the frequency of analysis, increasing the precision and timeliness of material reorders and reducing warehouses, maintaining the level of customer service by delivering products quickly and reliably.

A company that invests in tools to support the production and work of operators by increasing high added value activities, reducing repetitive and cumbersome ones. This is Gortani and this is the story of the implementation carried out by Link Management of the CyberPlan APS and Opera MES software, used respectively to plan production and to manage the production process.

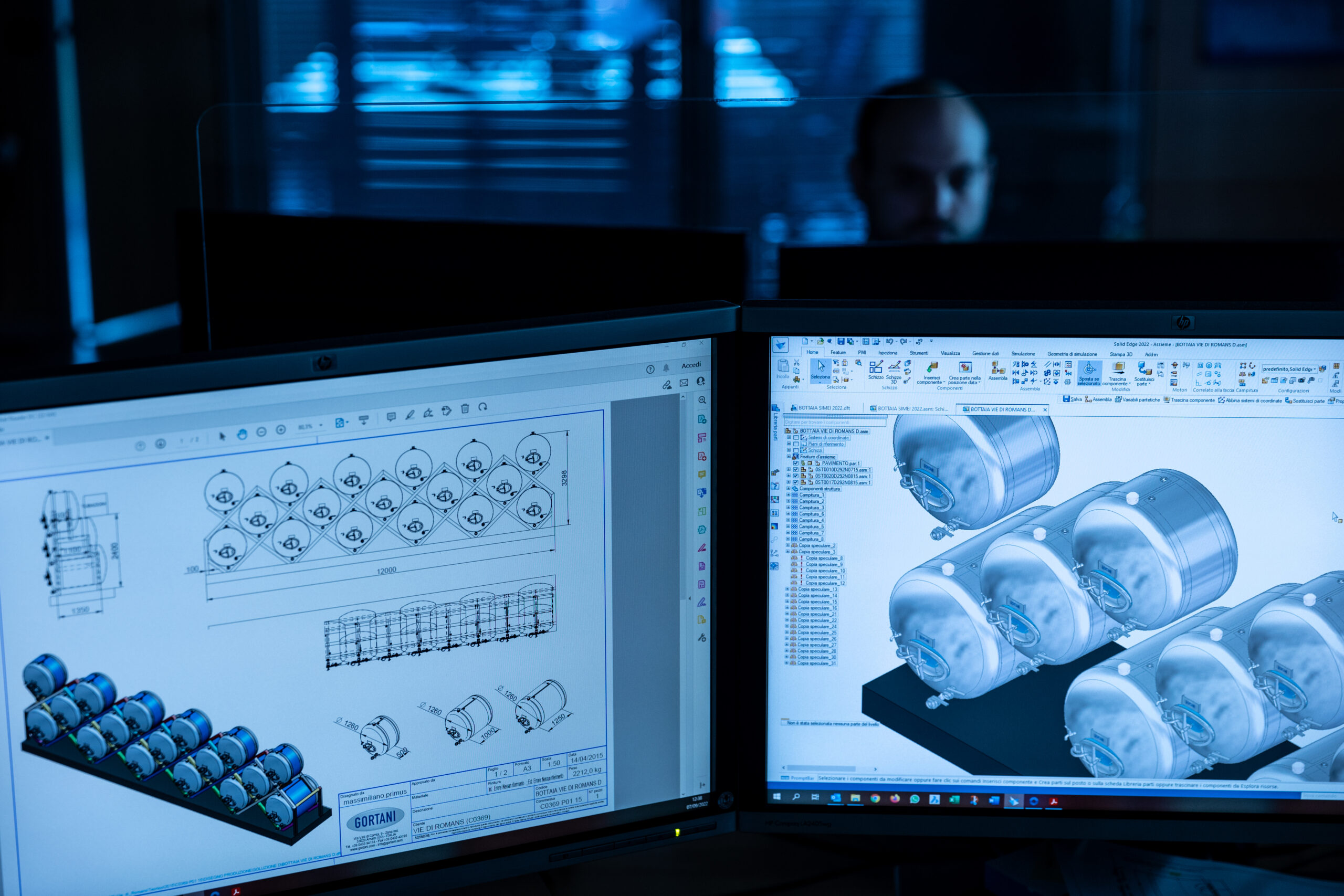

Gortani, autoclaves, tanks and avant-garde winemakers, all over the world

Gortani is the reference brand for the design and supply of machines and systems for oenology, from storage tanks to turnkey cellars. In addition to specialising in the production of autoclaves, tanks and winemakers, he has extensive experience in the winegrowing sector.

The company was founded in the 1960s in Arta Terme, Carnia, in the province of Udine by Gian Pietro Gortani. The need of the time was to produce steel tanks to be used in the family distillery, later evolved on the initiative of his son Gian Paolo Gortani, in the development of increasingly advanced tanks, winemakers and autoclaves.

The growth that followed led the company to exceed 200 employees and to move in 2002 to the new plant in Amaro, in the mountains of the Carnic Alps, which covers an area of about 30,000 square meters where 100% made in Italy quality products are exported all over the world.

The transfer to the new plant has allowed Gortani to increase its production capacity, today reaching about 1,500 tanks, 100 winemakers and 350 autoclaves on an annual basis, while improving efficiency and safety at work. In addition to these aspects, Gortani has always paid great attention to fully satisfying the needs of customers as well as respecting punctuality in the performance of its work. Finally, Gortani stands out for continuous innovation, complete internalisation of processes, traceability and attention to sustainability, understood at 360°.

The challenge: the motivations behind the project

In the last 10 years Gortani has quadrupled its turnover and the number of resources used, this aspect has brought with it a natural increase in the complexity of the production scenario.

In addition, operating in the food and beverage industry, the company often faces the same challenges as the market in which it operates:

- changes in preferences between customers and consequent adaptations of the products,

- local and international competition,

- technological innovation,

- environmental sustainability,

- digitization,

- local and international regulations.

These challenges, combined with the increasing complexity of production flows, have prompted Gortani to equip itself with automated production plants and new computer systems for all the staff working in the offices, including production planning.

With regard to production planning, in particular, the need for an advanced planning system has arisen due to several needs:

- keep material warehouses and supplies under control,

- there was a need to plan loads on production resources,

- speed up the procedures in use, which are too slow and complex,

- need to highlight items with a low turnover,

- need to increase the frequency of analyses.

In short, before the implementation of CyberPlan the procedure was very long and complex, it was done through the MRP of the management system in use every two weeks or so because the ERP needed a few hours to process all the needs. Instead, resources were managed through Excel spreadsheets.

The selection of APS software

To select the best solution, Gortani set up a software selection process.

Simplicity of implementation and subsequent use, added to the satisfaction of all requirements, have led to the choice falling on CyberPlan. The usability of the data was also better than other evaluated solutions and was a differentiating factor.

The project was developed in 6 months without significant difficulties, as the architecture of the CyberPlan system well matched the construction of the Gortani bills of materials and no substantial customizations were necessary as the company has adapted, where necessary, its processes to the standards of the new planning system.

The tanks and autoclaves of Gortani are produced in the plants of Amaro using in almost all cases stainless steel, in its different forms: coil, sheet metal or pipes, for example. The planning of these materials takes place through the explosion of requirements from the MRP and each part and component of the product to be made is coded and inserted into the bill of materials of the finished product.

The benefits of the APS project for Gortani

The CyberPlan implementation project has brought numerous benefits, both direct and indirect, both in the short and long term.

Among these, there was immediately what was perhaps the biggest difference between the before and after: the frequency of the analysis, which went from a twice-weekly to a daily one, with a consequent and drastic reduction in supply times.

To date, in fact, planning takes place daily or several times a day and this increase in frequency has made it possible to identify the critical materials to be ordered, from the moment the order is placed.

In addition, it was also possible to find and highlight all items with a low turnover faster and therefore reduce inventory stocks.

Through the use of CyberPlan, Gortani was able to define the reorder batches and inventory stocks, in a simple and immediate way, based on the consumption analysis.

Finally, today Gortani processes the purchase proposals that come from the planning on a daily basis, previously these proposals were made weekly.

MES for the supervision of the production process

In addition, the implementation of Opera MES for the sequencing of operations and the collection of factory data is in progress.

This MES, acronym for Manufacturing Execution System, will allow you to digitize all the information, both those that go to the departments such as specifications and drawings, and all the return data, adding additional benefits to the Gortani production department.

APS and MES to ensure production governance and customer satisfaction

Gortani’s project is therefore a virtuous and tangible example of the joint implementation of APS and MES software to manage planning and production in an innovative and modern way. These projects carried out by people inside and outside the company have made it possible to achieve ambitious objectives such as punctual and precise dates and the management of advanced logics with a small number of operators.

CyberPlan and Opera MES software are tools used to plan, schedule and manage the execution of the production department of a manufacturing company. The same companies can find other useful solutions dedicated to them within the Zucchetti group’s offer, such as AWMS or Replica Sistemi.

A project of the implementing partner Link Management

The project was carried out by Link Management, Cybertec’s partner for several decades, which was able to implement the CyberPlan and Opera MES solutions in manufacturing companies with productions of all kinds and types. The many years of experience guarantee winning and effective projects, closed in a short time and with great returns.