Being able to have visibility and control over production data is an ambition of many companies. One way to facilitate this process is through the introduction of a MES system, which allows you to make visible a lot of information related to production.

Whatis a MES Software?

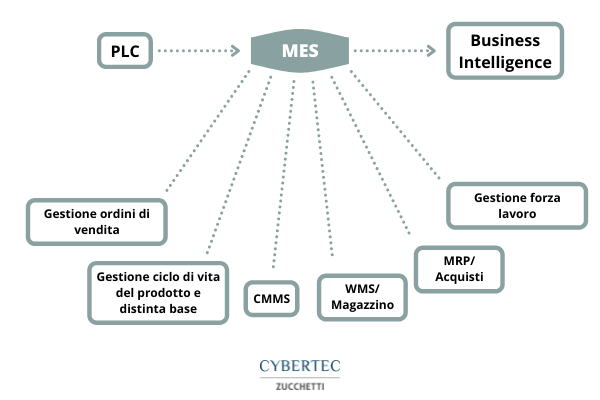

MES is the acronym for “manufacturing execution system” and indicates a computerized system for the control and optimized management of production through the collection of a series of current and accurate data. In this way, the MES acquires and distributes information on the various activities of the production departments, from the launch of the order to the finished product, offering a real-time overview of the entire production process.

The MES is able to align the company departments prepared for strategic management with production, giving useful information for the purposes of strategic choices and allowing to monitor the differences between what is planned and what is actually produced.

What is MES Software for?

The MES system has the valuable task of collecting production-related information and monitoring it in real time, putting ERP systems in communication with machine control systems and giving complete visibility into production.

When ERP systems and control systems do not interact with each other, the production process becomes a kind of black hole, where inputs and outputs are known but not what happens in the middle.

Therefore, the MES makes it possible to optimise production processes by keeping the availability of resources and the general quality of products under control. In fact, through a MES system it is possible to find answers to questions about the efficiency of the production process and solve doubts related to the occurrence of errors.

Which companies use MES Software?

Today the MES plays a key role in the strategic choices of many manufacturing companies, supporting many types of industries and their production processes, such as electronics, medical and pharmaceutical, automotive, semiconductors, aerospace, metals, plastics and so on.

In short, it is used in all those areas where not only the integration of machines is exploited with a view to an Industry 4.0, but where it is also able to support the scheduling processes, quality monitoring during the project phases and the management of raw materials.

In general, it could be said that MES is used by all those companies that make innovation and a broader vision their cornerstones. This is because the MES allows you to analyse a series of data present in the company that, if monitored, can lead to constant improvement over time since any inefficiencies are highlighted and resolved.

How to choose a MES Software?

The offer on the MES software market is quite wide and choosing which system is best suited to your needs may not seem easy. In fact, there are several characteristics that must be taken into account, but we must start from understanding what the business needs are and which solution best meets them.

One element that should definitely be taken into consideration is the ease of integration. The chosen MES system must in fact integrate seamlessly with the ERP and other systems already in use in the company, such as the APS. In this case, it is important that these already existing systems are also flexible and support integrations with other software well. In the case of APS, CyberPlan has the advantage of integrating well with the main ERPs and operating in synergy with the MES system.

Another indicator is the simplicity of configuration and how user–friendly it is. This is because a MES software is used by different figures within the company, both operators with more technical profiles and people working in the field of management. Therefore, it must be easily accessible to everyone.

Finally, the presence of transversal functionalities can also be taken into account, all integrated into a single application.

How much does a MES software cost?

An additional element to take into account in the selection phase is certainly the cost. Thanks to the breadth of the offer, it is possible to find solutions that meet different price ranges, however, you must be aware that the MES is not a ready-made software, but must be adapted and customized according to business needs, so the price can also vary greatly.

In fact, in addition to the monthly license (which can vary from hundreds of euros to a few thousand), the cost of a package of consulting hours must often also be added to understand the needs and identify the company’s objectives and the cost of tailored maintenance.

MES Software and CyberPlan

As already mentioned, CyberPlan is an APS for production planning that integrates seamlessly with MES software and other systems in the company. The integration between these two worlds greatly facilitates the exchange of information on production and consequently increases yield and performance.

Thanks to its flexibility, CyberPlan can be integrated with different MES software. A solution can also be found within the wide offer of the Zucchetti Group, opting for example for Opera MES, the Open Data software, which combined with an APS such as CyberPlan allows you to make the most of the synergies of the Group’s offer.

If you are interested in introducing these technologies in your company and finding out how they can improve performance, you can contact our expert without obligation who will answer all your questions.