How Sipa S.p.a. achieved a 30% increase in planning efficiency, thanks to the finite capacity production planning software, CyberPlan.

The company: electromechanical with a turnover of 1 billion euros

For 30 years Sipa has been designing, producing and selling on the world market all the technologies for the production, filling and secondary packaging of pet (Polyethylene Terephthalate) containers from the preform to the final product for beverages, foods, detergents, cosmetics and pharmaceuticals. Based in Italy, the company has 16 sales subsidiaries, 4 production plants (two sites in Italy, one in Romania and one in China) and 28 after-sales service centres for the provision of technical support and spare parts.

The challenge: planning in an advanced way, starting from SAP

Sipa S.p.a. needed to reduce the amount of hours needed to process MRP on ERP, in fact it was carried out at night.

It was also necessary to solve the complex management and maintenance of the applications grown as a corollary of the ERP system. At the business level, however, the objectives were:

- Maintaining the level of service as a competitive weapon;

- Reduction of contract costs;

- Increase in turnover of warehouses;

- Complexity in accessing information;

- Impossibility of having an overall view by order (SB) due to the lack of dynamic pegging on all bill levels;

- Impossibility of carrying out simulations in acceptable times;

- High number of data to be managed (registry of active codes: 324,000 with 1,122,000 bill links);

- Improve communication between entities.

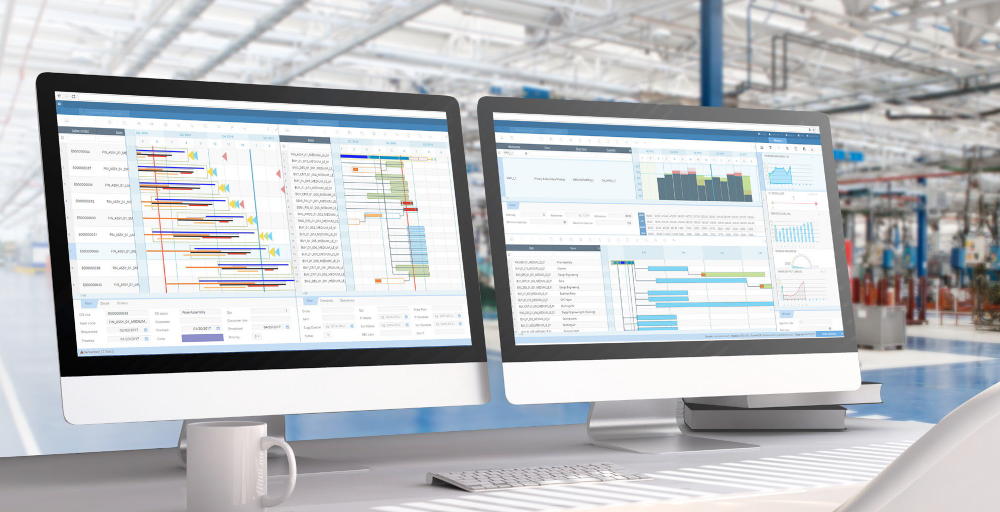

The solution: CyberPlan

The selected solution was the CyberPlan finite capacity production planning software, integrated into the existing IT reality in an effective and efficient way. The software, modelled on the company’s needs, has also made it possible to redesign production planning processes.

The results: reliable delivery dates and a high level of service

The most relevant KPIs (Key Performance Indicators) have increased considerably, reaching in a short time a:

- Increase in production planning efficiency (compared to appointments between orders): +30%

- Reduction in average warehouse coverage: -10%

READ THE CASE STUDY >