In the world of manufacturing, competitiveness is a continuous race against time. Managing resources, meeting deadlines and minimising errors along the production chain are daily challenges for companies. But how can you turn a production process into an efficient and flawless machine?

A concrete example comes from Fenex S.r.l., a Bartec group company, which has chosen to rely on CyberPlan, an Advanced Planning and Scheduling (APS) software, to face the challenges related to the increasing complexity of production processes and the high security standards required by the sector.

The adoption of CyberPlan marked a real breakthrough for Fenex, revolutionizing production planning and significantly improving the punctuality of deliveries, as well as minimizing errors along the production chain. This strategic step not only increased operational efficiency, but also consolidated the company’s position in the market, ensuring quality, reliability and safety at the highest levels.

real breakthrough for Fenex, revolutionizing production planning and significantly improving the punctuality of deliveries, as well as minimizing errors along the production chain. This strategic step not only increased operational efficiency, but also consolidated the company’s position in the market, ensuring quality, reliability and safety at the highest levels.

A case that demonstrates how the adoption of the right technology can make a difference and turn production management into a concrete competitive advantage.

Let’s explore together the challenges of structured and reliable planning and find out how Fenex tackled these complexities by adopting CyberPlan. We will delve into the strategic role of this solution within the company, the processes it has helped to optimise and, above all, the concrete results obtained: a more efficient management of resources, greater punctuality in deliveries and an overall improvement in production quality.

The Challenge: Structured and Reliable Planning

The growth of the company has highlighted the need for a planning system capable of responding to increasingly complex demand and stringent constraints. But which software to choose? After a careful evaluation of the available solutions, Fenex has opted for CyberPlan, recognized for its:

- Completeness of information: provides an integrated view of all production phases;

- Flexibility of use: also suitable for configured products;

- Ease of integration: allows a smooth data exchange between the management system and the planning environment.

The Implementation of CyberPlan: A Step Forward in Digitalization

Initially, CyberPlan was interfaced with the first company management system, exploiting the ERP module oriented to contract management for the creation of purchase requests and production orders. In the last five years, the use of CyberPlan has evolved considerably, allowing Fenex to:

- Verify the feasibility of the production plan: Through finite capacity simulations, evaluating both the presence of materials and the load on the most critical work centres.

- Disseminate operational information: The plans obtained daily are communicated to production departments, warehouse, purchasing office, Bartec sales offices and direct customers, thus defining the feasible delivery dates.

CyberPlan is also used to compare the load on the assembly department with that of the other Italian Bartec plant in Trezzano sul Naviglio, during weekly joint meetings for the management of sales orders.

In May 2023, with the move to the new ERP, it was decided to integrate Infor LN with CyberPlan to take advantage of its advanced simulation and scheduling capabilities.

The Role of the Planner: from Coordinator to Strategist

In the past, planning management was entrusted exclusively to the production manager, who coordinated the departments based on his own experience. With the adoption of CyberPlan, the figure of the planner emerged, which has become fundamental for:

- Optimise the management of materials and resources: Taking into account not only the availability of materials, but also the production capacity of the departments.

- Reduce errors and inefficiencies: Monitoring data that, although not always perfect, allow you to export purchase proposals and more reliable production orders, thus containing the propagation of errors along the supply chain.

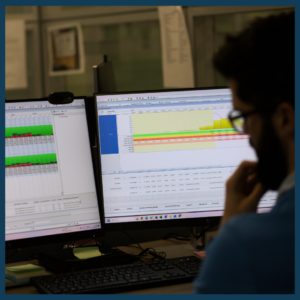

CyberPlan, managed by the Operations Team, acts as an information collector, aggregating and disaggregating data in order to ensure total visibility. The platform communicates sales orders, production capacity and scheduling, offering display windows that allow a quick analysis of the status of orders, thanks also to the presence of pegging that uniquely connects purchase and production orders to sales orders.

With CyberPlan, the figure of the planner has increasingly emerged, fundamental in terms of production efficiency and cost savings. Giulia Beinat – Production Manager states. Watch the full video interview here.

Tangible Results

The adoption of CyberPlan has brought concrete and measurable benefits:

- Optimize production planning: Exporting, on worksheets, the list of production orders organized by reference, status and start date of processing. This facilitated the alignment between the departments on the progress of the orders.

- Analyse specific KPIs: such as the use and production efficiency at the level of machines and workbenches, improving the response to market needs.

- Achieve high standards of punctuality: With an On Time Delivery (OTD) rate of around 90% on confirmed delivery dates.

- Dealing with load increases: The visibility of the available production capacity has made it possible to implement timely corrective measures.

A Model for the Future of Manufacturing

Fenex’s history shows that adopting advanced APS software like CyberPlan is not only an option, but a necessity for modern manufacturing companies.

Investing in technology means improving efficiency, reducing margins of error and ensuring greater competitiveness in the market. So, the real question is: do you also want to transform your company into a model of efficiency and reliability?